Biodegradable Ether Carboxylic Acid-based Hypoallergenic Detergent Base"BEAULIGHT LCA-25N"

What's great about ether carboxylic acid type detergent base

"BEAULIGHT LCA-25N"

1

Hypoallergenic

-As a hypoallergenic detergent, "BEAULIGHT LCA-25N" is suitable for sulfate-free shampoos, body soaps, etc.

-"BEAULIGHT LCA-25N" is an ether carboxylic acid that uses a unique narrow ethoxylation technology (*) and has low skin and eye irritation.

*This technology produces ether carboxylic acids with a narrow distribution of ethylene oxide added and low unreacted higher alcohol content.

2

Biodegradable

"BEAULIGHT LCA-25N" is an ether carboxylic acid surfactant made from naturally occurring alcohols. It is highly biodegradable.

2

Foamability

Even with its weak acidity, "BEAULIGHT LCA-25N" exhibits good foaming properties and is characterized by a refreshing wash.

4

Hard water resistance

Good hard water resistance.

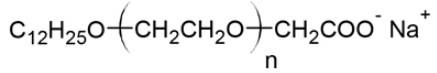

Ingredient Information

| Cosmetics labeling name | Sodium laureth-4-carboxylate |

|---|---|

| Evaporation Residue | Approx. 28wt% |

| Appearance | Colorless to pale yellow liquid |

| Molecular structure |  |

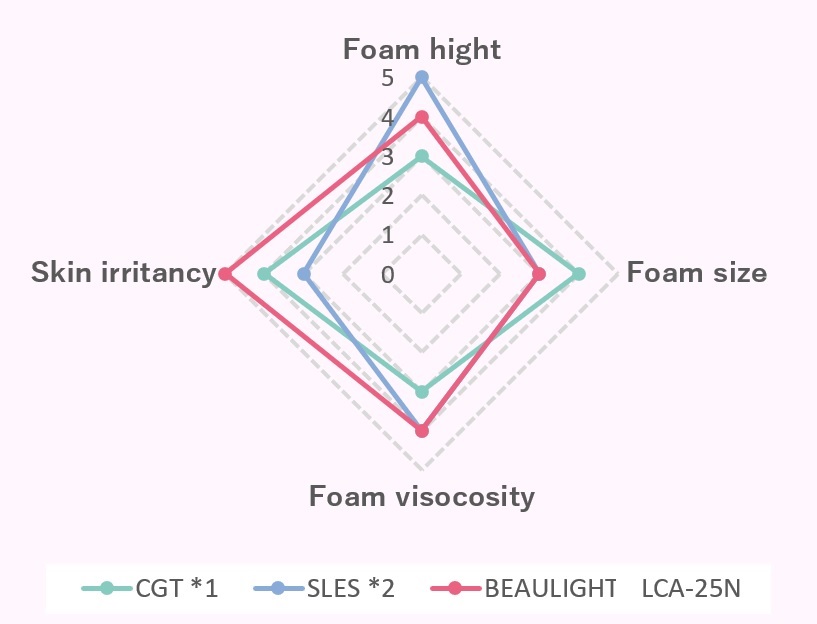

Performance of "BEAULIGHT LCA-25N"

Performance comparison chart with CGT (TEA cocoyl glutamate) and SLES (sodium laureth sulfate)

Fig. Performance Comparison Chart

*1 CGT: Cocoyl glutamate TEA

*2 SLES: Sodium laureth sulfate

Hypoallergenic

Compared to CGT and SLES, it is hypoallergenic and gentler on the skin.

Foam height and size

Forms bubbles comparable to those of general anionic surfactants.

Foam viscosity

It shows the same foam viscosity as SLES, and forms moist and glossy foam.

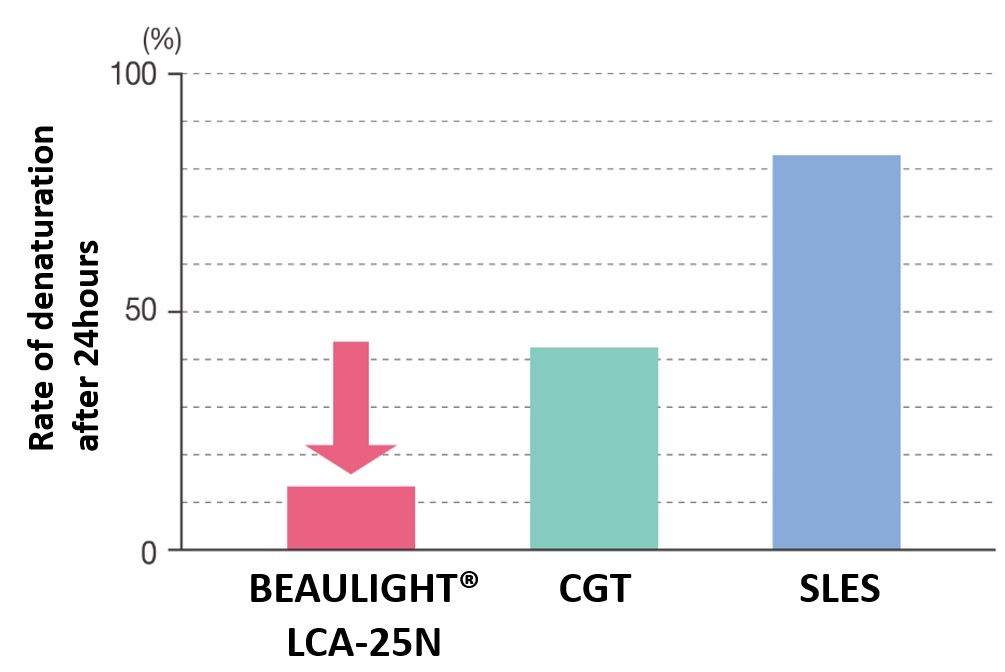

Protein denaturation rate (irritation)

Fig. Protein denaturation rate in each detergent base

*1 CGT: TEA cocoyl glutamate

*2 SLES: Sodium laureth sulfate

Sanyo Chemical's proprietary "narrow ethoxylation technology" allows for use as a cleaning base for shampoos and body soaps with minimal irritation.

Test Method

Protein: 0.05% albumin solution

Active agent concentration: 1.0% aqueous solution of active ingredient

(SLES (sodium laureth sulfate) is measured as a standard)

Bath ratio: albumin aqueous solution/activator aqueous solution = 9/1

Denaturation temperature: 20-25°C x 24 hours

Quantitative method: High performance liquid chromatography (HPLC)

Formula

Protein denaturation rate (%)= {(peak height of blank after 24 hours)-(peak height of sample solution after 24 hours)} / (peak height of blank after 24 hours) × 100

Hard water resistance

"BEAULIGHT LCA-25N" has good hard water resistance equivalent to SLES (sodium laureth sulfate).

| Surfactant | Hard water resistance (mL) |

|---|---|

| BEAULIGHT LCA-25N | ≧ 200 |

| SLES (Sodium laureth sulfate) | ≧ 200 |

| CGT (TEA cocoyl glutamate) | 1 |

Application data

Example formulation: Sulfate-free high foaming shampoo

| INCI name | Product name | Formulation (wt%) |

|

|---|---|---|---|

| A | water | 18.45 | |

| sodium benzoate | 0.3 | ||

| B | Polyquaternium-10 | 0.5 | |

| water | 25 | ||

| C | Cocamidopropyl betaine |

LEBON HC-30W |

10 |

| Sodium laureth 4-carboxylate | BEAULIGHT LCA-25N | 35 | |

| Sodium lauryl carboxylate | BEAULIGHT SHAA | 5 | |

| D | Polyquaternium-47 | 0.7 | |

| water | 1.4 | ||

| E | Cocamide DEA | PROFANEXTRA 24 | 3 |

| phenoxyethanol |

NEWPOL EFP |

0.5 | |

| F | citric acid | 0.15 | |

|

Total |

100.0 | ||

- A: Dissolve uniformly at room temperature.

- B: After stirring and dispersing at room temperature, heat to 70-75°C to dissolve uniformly, and then feed into A at room temperature to mix uniformly.

- Dissolve C uniformly in the A+B mixture at room temperature.

- While stirring the mixture of A+B+C at room temperature, add D and dissolve uniformly.

- Put E into the mixture of A+B+C+D and stir uniformly.

- F is added to the mixture of A+B+C+D+E and the pH is adjusted to 5.5-6.0.

- After uniformly stirring, cool and defoam.

Related Infomation

Related Products

| Cosmetic raw materials |

|---|

| Links to Sanyo Chemical's corporate site |

|---|

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist