Polyoxyalkylene alkylamine-based detergent base for clothes"PUREMEEL EP-300S"

Base detergent for clothes with excellent cleaning power against grease and oil stains

What's great about Sanyo Chemical's polyoxyalkylene alkylamine-based detergent base "PUREMEEL EP-300S".

1

Excellent cleaning power

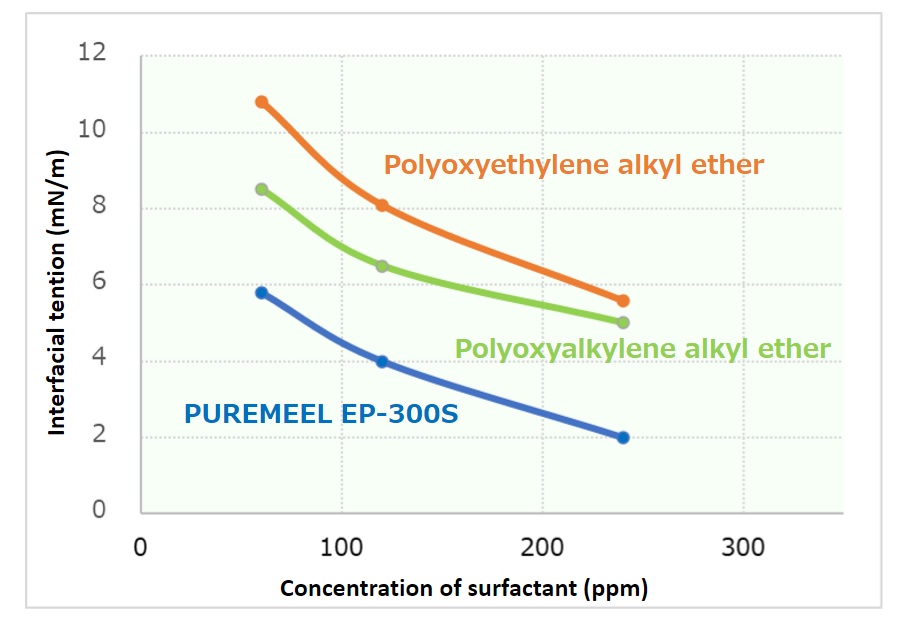

Compared to other nonionic surfactants, "PUREMEEL EP-300S" exhibits excellent surface tension lowering ability against oil and grease even at low concentrations, and demonstrates high cleaning power against oil and grease stains.

Fig. Comparison of interfacial tension lowering ability for fats and oils

Test Method

Sample

The surfactants shown in the left figure were diluted in water to various concentrations and used as samples.

Method of measuring interfacial tension

The interfacial tension between the sample and the following artificial fat composition at 25°C was measured by the pendant drop method using the fully automatic interfacial tension measuring device "Model PD-W" [Kyowa Interface Science Co.,Ltd

Composition of artificial fats and oils (mass ratio)

Oleic acid: 45.0 Fluid paraffin: 4.0 Triolein: 25.0 Squalene: 4.0 Cholesterol olate: 19.5 Cholesterol: 2.5 Total: 100.0

2

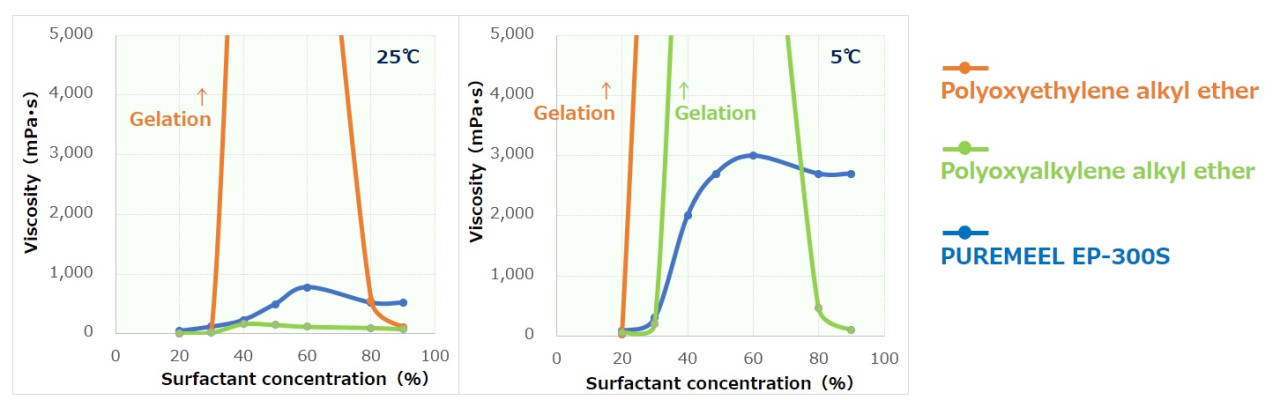

Good water solubility and handling

"PUREMEEL EP-300S" has good solubility in water, and even when diluted with water, the increase in viscosity is small, making it easy to handle. "PUREMEEL EP-300S" also has good flowability at low temperatures.

Fig. Relationship between surfactant concentration and viscosity

( Left:25°C) (Right 5℃)

Measurement Method

Viscosity of aqueous surfactant solutions at various concentrations was measured at 5°C and 25°C using a Type B viscometer.

3

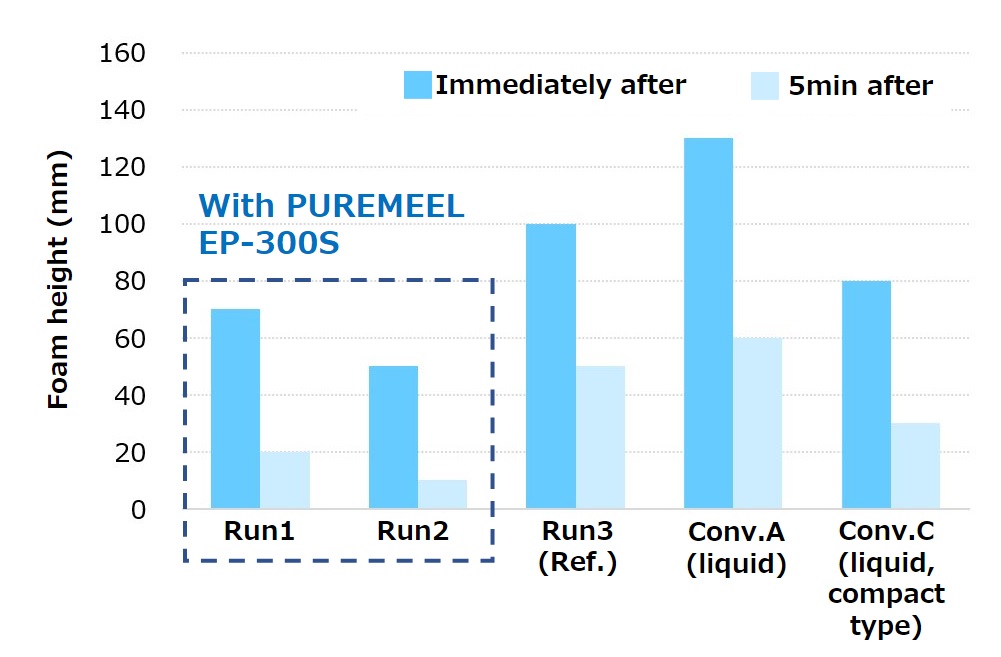

Good foam breaking

Good foam breaking and easy rinsing.

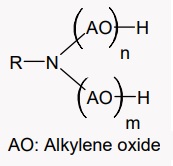

Composition and main properties of "PUREMEEL EP-300S"

| Composition | Polyoxyalkylene alkylamine (see left) |

|---|---|

| Appearance | Pale yellow to yellow liquid |

| pH | Approx. 9 (10 mass% water dilution) |

| Moisture content | Approx. 0.1 mass% (Karl Fischer method) |

| Viscosity | Approx. 600 mPa-s (25°C) |

| Cloud point | Approx. 81°C |

Cleaning Power Data of "PUREMEEL EP-300S"

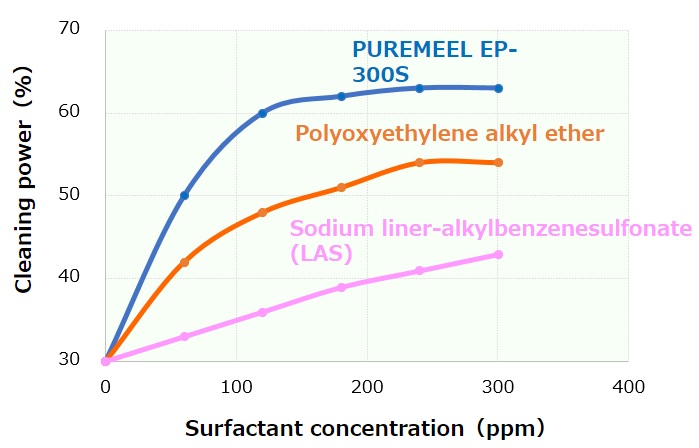

Surfactant concentration and cleaning power (enzyme-containing systems)

"PUREMEEL EP-300S" exhibits superior cleaning power compared to other nonionic and anionic surfactants.

Fig. Surfactant concentration and cleaning power (enzyme blended system)

Test Method

Sample

4 mg of enzyme [Bioplase APL-30K, Nagase ChemteX Corporation] was added to 1 L of diluted solution of the surfactants shown in the left figure, diluted with water to each concentration, and used as the sample.

Method of measuring washing power

Ten wet-type artificially contaminated fabrics [manufactured by Japan Laundry Science Institute] were washed and rinsed using a Turgotometer [manufactured by DAIEI KAGAKU SEIKI MFG. CO., LTD] under the following conditions, and dried in a circulating air dryer at 60°C for 30 minutes. The reflectance of the white cloths and the contaminated cloths before and after washing were then measured at a wavelength of 540 nm using a spectrophotometer (NIPPON DENSHOKU INDUSTRIES CO.,LTD), and the washing power was calculated from the following formula.

Washing conditions: 1L of sample at 25°C for 10 minutes at 85 rpm

Rinsing condition: 1L of water at 25°C for 1 minute at 85 rpm

<Formula for washing power>

Washing power = (reflectance after washing - reflectance before washing) x 100 / (reflectance of white cloth - reflectance before washing)

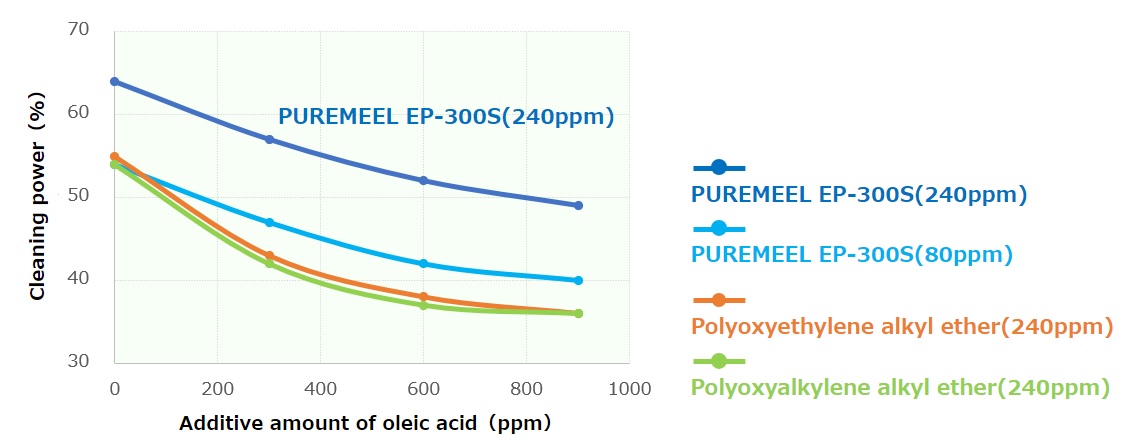

Cleaning power in the presence of oleic acid (enzyme-containing system)

"PUREMEEL EP-300S" shows superior cleaning power at lower concentrations than other nonionic surfactants, even in the presence of oleic acid, a fatty acid.

Fig. Cleaning performance in the presence of oleic acid (enzyme blended system)

Test Method

Sample:

To 1 L of diluted solution, in which the surfactant shown in the above figure was diluted with water to various concentrations and a prescribed amount of oleic acid was added 4 mg of enzyme [Bioplase APL-30K, Nagase ChemteX Corporation] was added to 1 L of diluted solution.

Method of measuring detergency:

Same as the method described above.

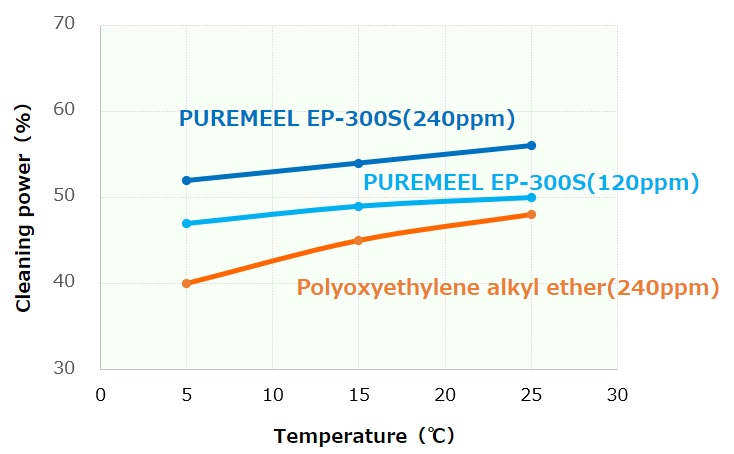

Cleaning temperature and cleaning power

"PUREMEEL EP-300S" exhibits superior cleaning power even at low temperatures compared to other nonionic surfactants.

Fig. Washing Temperature and Washing Power

Test Method

Sample

The surfactants shown in the left figure were diluted with water to various concentrations and used as samples.

Method of measuring washing power

Same as the method described above. However, washing was also performed at 5°C and 15°C.

Performance as a base for liquid laundry detergent

The table below shows an example of a formulation using “PUREMEEL EP-300S” as a liquid detergent for clothes.

In addition to its high detergency against oil and grease stains, hard water resistance, and good rinsing properties, “PUREMEEL EP-300S” has excellent flowability, making it easy to increase the concentration of detergent and reduce the amount of solvent used.

In addition, the resulting detergent is slightly alkaline, so the amount of alkalizing agent added for pH adjustment can be reduced.

Formulation Example

Regular type detergent formulation

| Component | Name | Example of formulation (1) | Example of formulation (2) | Ref. Example of formulation (3) | Ref. Example of formulation (4) | |

|---|---|---|---|---|---|---|

| Formulation(by mass) | Surfactant | PUREMEEL EP-300 | 7.5 | 10 | ー | ー |

| EMULMIN NL-100 *1 | 7.5 | 2 | 30 | 30 | ||

| Solvent | propylene glycol | ー | ー | 10 | 10 | |

| Stabilizer | boric acid | 1 | 1 | 1 | 1 | |

| Thickener | EMULMIN 862 *3 | 2 | 2 | ー | ー | |

| Alkalizing agent | triethanolamine | ー | ー | 3 | ー | |

| Enzyme | Protease *3 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Diluent | water | remaining quantity | remaining quantity | remaining quantity | remaining quantity | |

| Total amount | 100 | 100 | 100 | 100 | ||

| Standard usage amount g (per 30L water) | 25 | 25 | 25 | 25 | ||

| Detergent properties | Viscosity mPa-s(25°C) | 85 | 80 | 90 | 90 | |

| pH (1 mass% water dilution) | 8.2 | 8.3 | 8.5 | 6.2 | ||

| Low temperature flowability (5°C) | Good | Good | Good | Good | ||

Compact type detergent formulation

| Component | Name | Example of formulation (5) | Example of formulation (6) | Ref. Example of formulation (7) | |

|---|---|---|---|---|---|

| Formulation(by mass) | Surfactant | PUREMEEL EP-300 | 50 | 30 | ー |

| EMULMIN NL-100 *1 | ー | ー | 50 | ||

| Solvent | propylene glycol | 10 | 10 | 10 | |

| Stabilizer | boric acid | 1 | 1 | 1 | |

| Enzyme | Protease *3 | 0.5 | 0.5 | 0.5 | |

| Diluent | water | remaining quantity | remaining quantity | remaining quantity | |

| Total amount | 100 | 100 | 100 | ||

| Standard usage amount g (per 30L water) | 10 | 10 | 10 | ||

| Detergent properties | Viscosity mPa-s(25°C) | 150 | 100 | 180 | |

| pH (1 mass% water dilution) | 8.5 | 8.3 | 8.4 | ||

| Low temperature flowability (5°C) | Good | Good | Poor | ||

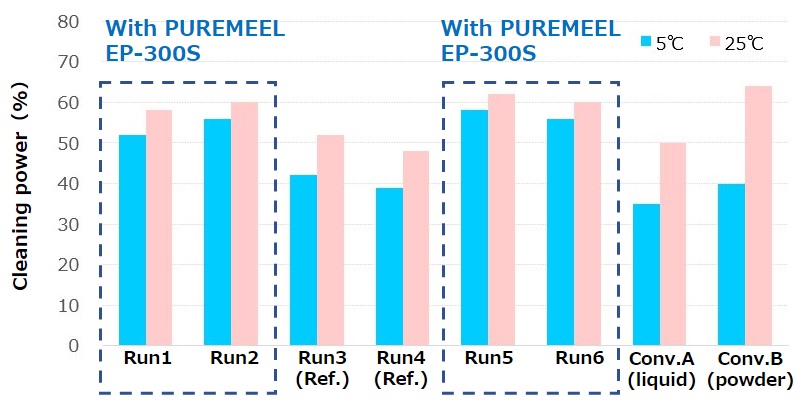

Comparison of cleaning power

Run (1), (2), (5), and (6) using "PUREMEEL EP-300S" exhibited higher cleaning power than conventional formulations and commercial products.

Fig. Comparison of cleaning power

Test Method

Sample

The sample was a diluted solution of each of the aforementioned formulation examples of laundry detergents and standard usage amounts of commercial detergents [25 g (per 30 L of water) for regular-type liquid detergent of commercial product A, 20 g (per 30 L of water) for regular-type powder detergent of commercial product B] in water.

The sample was a diluted solution of each of the aforementioned formulation examples and standard usage amounts of commercial detergents [25 g (per 30 L of water) for regular liquid detergent of commercial product A, and 20 g (per 30 L of water) for regular powder detergent of commercial product B].

Method of measuring detergency:

Same as the method described above.

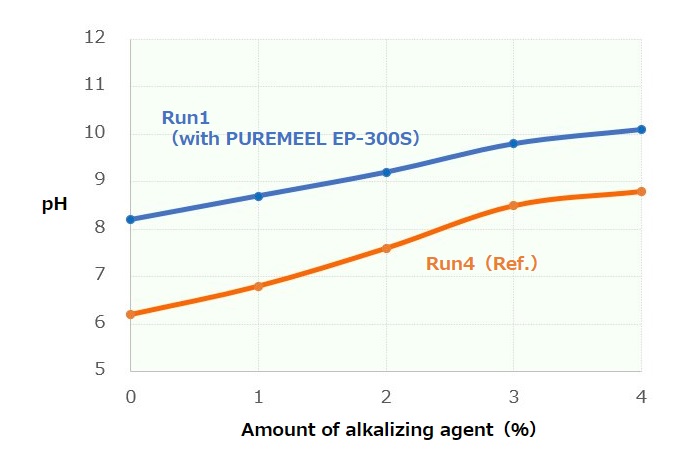

pH of example formulation

Detergents using "PUREMEEL EP-300S" exhibit weak alkalinity.

The amount of alkalizing agent added in pH adjustment can be reduced.

Fig. Relationship between alkalizing agent addition and pH

Test Method

Sample

A sample was prepared by adding a prescribed amount of triethanolamine as an alkalizing agent to the aforementioned laundry detergent formulas (Example 1) and (Example 4).

Method of pH measurement

The pH of a 1 mass% aqueous dilution of the sample was measured at 20°C.

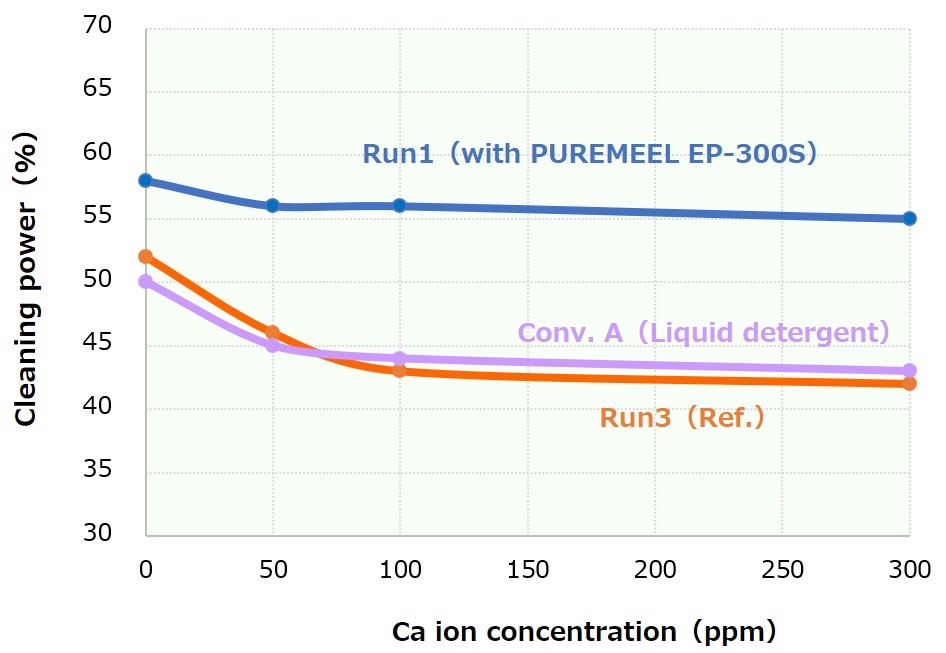

Hard water resistance

"PUREMEEL EP-300S" can be used to produce detergents with excellent hard water resistance.

Fig. Cleaning power at various Ca ion concentrations

Test Method

Sample

A sample was prepared by adding an amount of CaCl2 to 1 L of water dilution solution of the aforementioned laundry detergent formulas (1) and (3) and the standard usage amount of commercial detergent [25 g (per 30 L of water) for commercial product A regular type liquid detergent] to reach the Ca ion concentration shown in the figure on the left.

Method of measuring washing power

Same as the method described above.

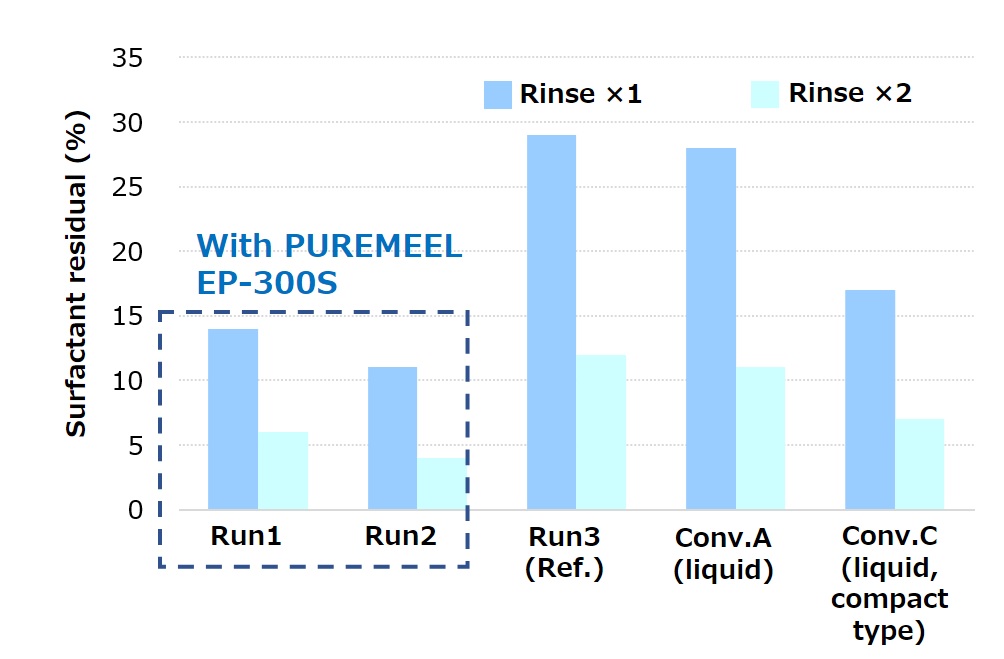

Detergent residue on clothes after rinsing

"PUREMEEL EP-300S" can be used to prepare detergents with good rinsing and foam breakage with low detergent residue on clothes.

Fig. Foam breakage after rinsing

Fig. Surfactant residual after rinsing

Test Method

Samples were water diluted solutions of the aforementioned formulation examples of laundry detergents and standard usage amounts of commercial detergents [25 g (per 30 L of water) for commercial product A regular type liquid detergent, 10 g (per 30 L of water) for commercial product C compact type liquid detergent].

Methods for measuring rinse water foam breakage and surfactant residual rate from rinsing

A washing machine [Panasonic Corporation, NA-FD8005S] was used to wash and rinse 2 kg of clean test cloths under the following conditions, and the effluent from the first and second rinses was collected. Next, 20 mL of the wastewater from the first rinse was placed in a 100 mL stoppered measuring cylinder and shaken 20 times by hand, and the height of the foam was measured immediately after shaking the cylinder and 5 minutes later to determine the foam breaking ability. Next, the surfactant residual amount in the wastewater from the first and second rinses was quantitatively analyzed by LC-MS [LC-MS2010EV by Shimadzu Corporation], and the surfactant residual percentage was calculated from the sample concentration (standard usage volume) and surfactant residual amount using the following formula.

Washing conditions:

A volume of sample at 20°C that fills the middle water level of the washing machine was used for 9 minutes.

Rinsing conditions:

5 minutes, twice, using a volume of 20°C water that fills the middle water level of the washing machine.

<Surfactant Residual Rate Calculation Formula>

Surfactant Residual Rate % = Detected concentration by LC-MS ppm × 100 / Sample concentration ppm

Related Information

Related Products

-

Polyether products

-

Link to Sanyo Chemical's corporate website

-

PUREMEEL CCS-80, PUREMEEL CF-60, PUREMEEL EP-300S, PUREMEEL EP-360, PUREMEEL PPE-103

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist