Ionic Liquid

Offering a Wide Variety of Solutions

as one of the World's Largest Ionic Liquid Suppliers

What is Great about Sanyo Chemical's Ionic Liquids

- Possesses synthesis technology with high purity and high design flexibility

- Our proprietary technology enables the production of halogen-free ionic liquids

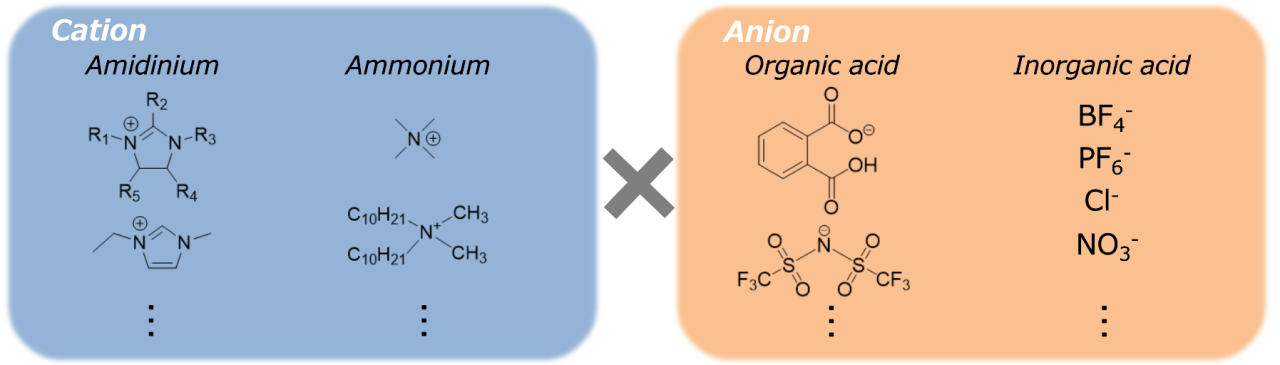

- A wide variety of cations and anions can be combined to provide the optimal composition to meet your needs

(over 20 years of production experience).

What is an Ionic Liquid?

A salt (a compound consisting of a cation and an anion) that has a low melting point and is a liquid near room temperature.

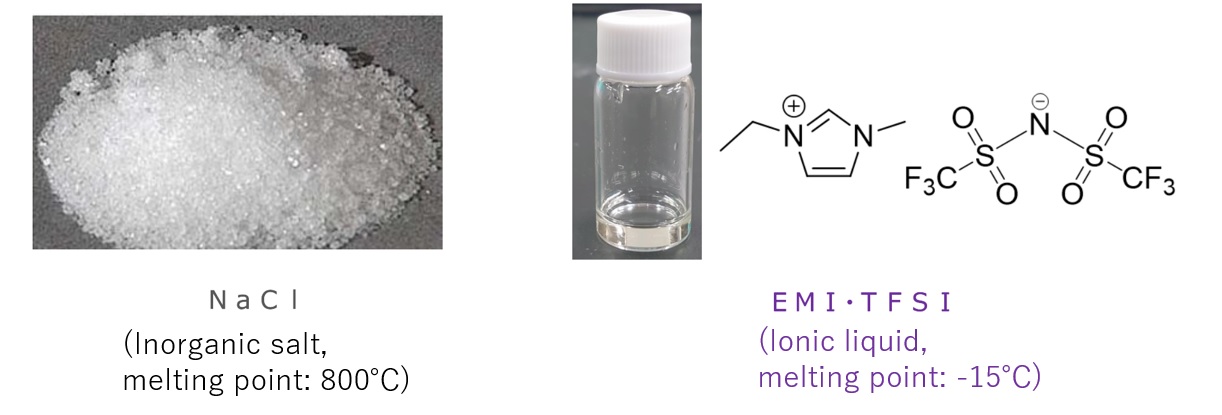

Comparison of Appearance of Inorganic Salts and Ionic Liquids

Main Features of Ionic Liquids

1

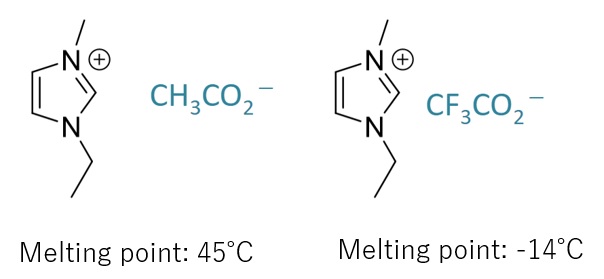

Low Melting Point

Ionic compounds generally have a high melting point, while ionic liquids have a low melting point due to their structure that weakens interactions and inhibits crystallinity.

(The melting point can be controlled by molecular design and combination of anions and cations.)

Lower electron density of ionic groups due to electron-withdrawing groups, etc., results in a lower melting point

2

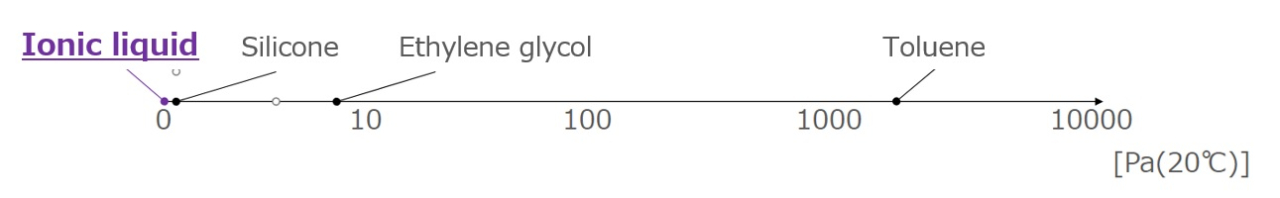

Low Volatility

The vapor pressure is very low due to the presence of electrical interactions between ions. There is little concern about air pollution or ignition due to volatilization.

Difference between organic solvents and ionic liquids

| Organic solvent | Ionic liquid |

|---|---|

|

|

Vapor pressure of each liquid

3

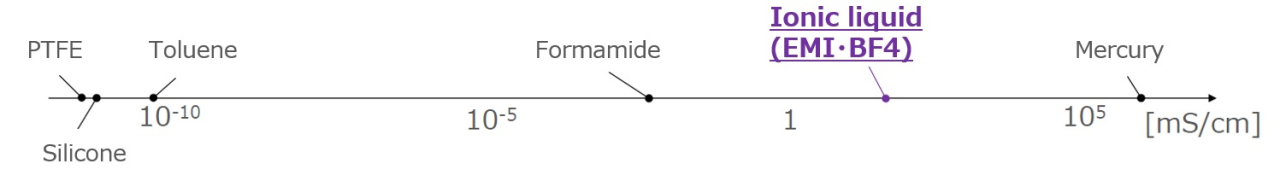

High Ionic Concentration and High Conductivity

Since it is composed solely of ions, it has a high ionic concentration and high electrical conductivity.

Electrical conductivity of each liquid

4

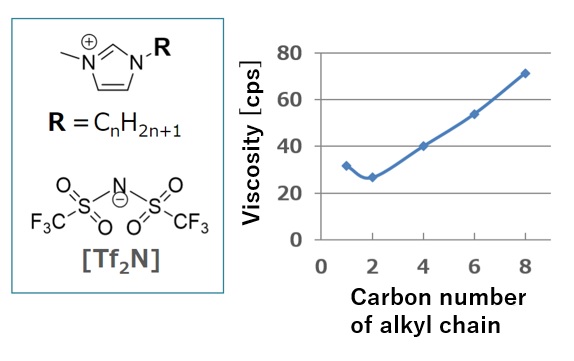

Wide Range of Structural Design

Since organic ions are used, the physical properties can be adjusted according to the application.

Relationship between alkyl chain length and viscosity

Viscosity increases as van der Waals forces increase due to elongation of alkyl chains, etc.

Examples of Industrial Applications of Ionic Liquids

Industrial Applications of Ionic Liquids Part 1: Electrolyte for Capacitors

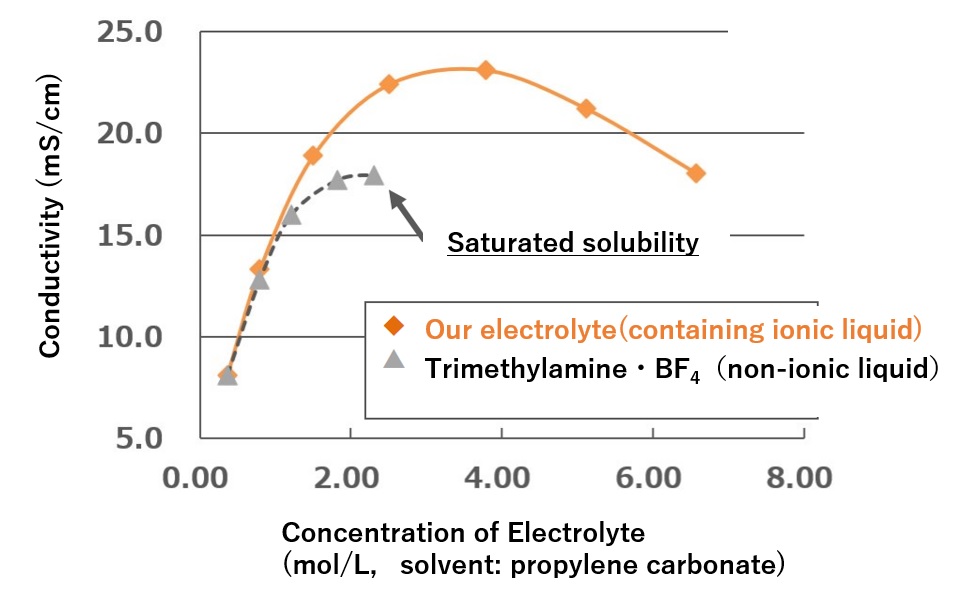

Why Ionic Liquids are Used as Electrolyte for Capacitors?

- Low melting point: No precipitation even at low temperatures

- High conductivity: High conductivity can be achieved by increasing the concentration of electrolyte

Conductivity and Low Temperature Solubility Data for Ionic Liquids and General Amine Salts

| Our electrolyte (Ionic liquid) |

Triethylamine phthalate (Non-ionic liquid) |

|

|---|---|---|

| Conductivity mS/cm(@30℃) | 14.2 | 6.0 |

| Low temperature solubility( -55℃) | Good (Dissolution) | Poor (precipitation) |

High Conductivity by Ionic Liquids

Industrial Applications of Ionic Liquids Part 2: Antistatic Agent

Why Ionic Liquids are Used as Antistatic Agents

- High conductivity and low melting point: Antistatic properties even in low-moisture (low-humidity) environments

- Low volatility: Stable retention in resin

- Design freedom: adjustable compatibility with resins

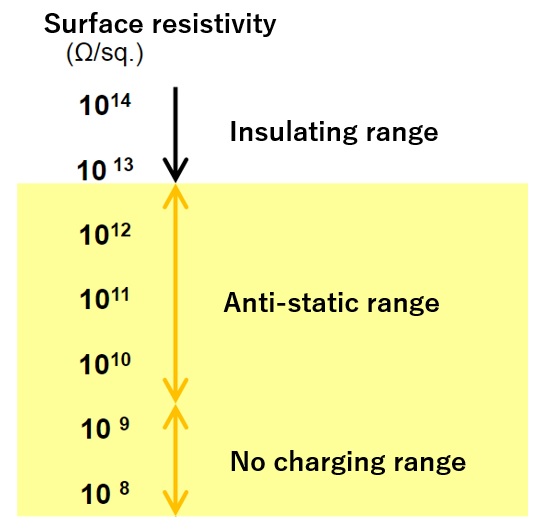

Difference in antistatic properties depending on humidity

Since ionic liquids have electrical conductivity on their own, they do not need to adsorb water on their surfaces as conventional surfactants do, and are less affected by humidity.

| Antistatic agent* | Surface resistance (Ω/sq.) | |

|---|---|---|

|

25℃ 75%RH |

25℃ 25%RH |

|

| Without addition | 3×1015 | ≧1×1016 |

| Surfactant | 4×1010 | 9×1014 |

| Ionic liquid | 8.5×1010 | 9×1010 |

*2wt% by weight added to acrylic resin

Relationship between surface resistance and antistatic properties

Antistatic Agent - Fluorine-free ionic liquid product developed by our company

Our developed product uses a composition that does not contain fluorine elements and has low corrosiveness.

In addition, its large molecular size makes it difficult to bleed out.

Industrial Applications of Ionic Liquids Part 3: CO2 Gas Absorbent

Why Ionic Liquids are Used

- Low volatility: Low loss in process

- Design freedom: Can be selectively structured to easily adsorb CO2

(1)Adsorption in crevices due to its bulky structure (physical adsorption)

(2)Reacts with CO2(chemisorption)

Industrial Applications of Ionic Liquids Part 4: Biomass Field

Cellulose Dissolving and Dispersing Agent

Cellulose: A major component of trees. Expected as a biomass resource.

Advantages of Ionic Liquids

- High ionic concentration: Hydrogen bond breakage enables dissolution of poorly soluble cellulose

- Design freedom: Development of optimal structure for dissolution is possible.

Industrial Applications of Ionic Liquids Part 5: Drive Components

High Performance Lubricant for Use Under Vacuum Conditions

- Design flexibility: Adjustable viscosity to suit the lubricant

- Stability: Does not decompose even in harsh environments

- Non-volatile: Lubricity can be maintained even under high vacuum conditions

Industrial Applications of Ionic Liquids Part 6: Medical Field

Solvents for Transdermal Drug Delivery (DDS)

- High ionic concentration enables dissolution of poorly soluble drugs using hydrogen bonding

- Combination of hydrophobic ions can improve skin penetration

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist