Low Molecular Antistatic Agents"CHEMISTAT"

Here is what's Great about Sanyo Chemical's Low Molecular Weight Antistatic Agents "CHEMISTAT"

Pigment Dispersant and Antistatic Agent for Paints and Inks for Flexible Packaging Materials ("CHEMISTAT 3500")

Eliminates the need to add pigment dispersant and antistatic agent separately, and improves workability.

Applicable not only to solvent inks but also to water-based inks.

We also have a lineup of low-molecular-weight antistatic agents that can be used in kneaded and coated forms.

Importance of Pigment Dispersants ("CHEMISTAT 3500")

Paints and inks are composed of resins that form the coating film, pigments and dyes that produce colors, solvents and water that dilute the resins and dyes, and additives that condition the coating film and disperse the pigments. Pigments are more durable than dyes and do not deteriorate easily when exposed to rain and wind outdoors, so pigments are mainly used in paints and inks.

The first role of paints and inks is to produce beautiful colors. To achieve this, it is important that the pigments that make up the color be uniformly dispersed in the paint or ink. However, since pigments tend to cluster together, simply mixing pigments in water or solvent will cause them to cluster together and solidify in the paint or ink.

Pigment dispersants play a role in preventing pigments from gathering together. Pigment dispersants enter the space between pigments and solvents or water and serve as a link between the two, creating a stable state in which pigments do not gather even in liquids.

Optimal pigment dispersion not only ensures beautiful colors, but also maintains the proper viscosity to allow paints and inks to set well and be easy to work with, as well as to prevent pigment precipitation due to long-term storage. Thus, pigment dispersants are indispensable components of paints and inks.

Static Electricity Prevention is also an Important Function to Prevent "Stringing" or Catching Fire("CHEMISTAT 3500")

When printing on thin films such as food packages, static electricity generated in the printing process can lead to unexpected accidents as well as poor quality. Therefore, it is important to suppress static electricity.

Since soft packaging materials such as film and ink both have properties that do not conduct electricity well, static electricity is easily generated in the printing process.

Examples of Static Electricity Problems

"Stringing"

A phenomenon in which ink disperses in a thread-like pattern around pictures and characters due to electrostatic repulsion.

If this occurs, the printed material becomes unusable, which affects the yield rate.

Sparks

Film is wound onto large rolls after printing, and static electricity is also generated when the printed material is peeled off the rolls.

If sparks ignite the film it could cause a fire in the worst case.

Limitations of Countermeasures by Static Eliminator

To prevent problems caused by static electricity, static eliminators are usually used to mechanically release the electricity.

However, there are places where static eliminators cannot reach, so measures are taken such as adding special additives to inks and films to prevent static electricity. In the printing of films and other soft packaging materials, the prevention of static electricity, which can cause defective products and accidents, is another indispensable function of ink.

"CHEMISTAT 3500" Combines

Pigment Dispersion and Antistatic Function

Thus, paints and inks require both pigment dispersion and antistatic functions, but generally separate additives are used for each. Sanyo Chemical's "CHEMISTAT 3500" is a unique product that combines both of these functions.

It is a long-running product that has been used since the 1960s, and is employed in a variety of inks, especially in the field of printing soft packaging materials, such as packages for confectioneries, frozen foods, and retort pouch foods. The fact that a single additive has two functions, eliminating the need to add each additive separately is a major advantage of this product, and it is highly evaluated by customers not only for its functionality but also for its ease of use.

"CHEMISTAT 3500" is compatible with oil-based solvents as well as water , and is expected to make a significant contribution to the shift to water-based inks. Sanyo Chemical continues to develop pigment dispersants that can contribute to both prosperous living and environmental protection in the world of inks, where water-based inks are being developed.

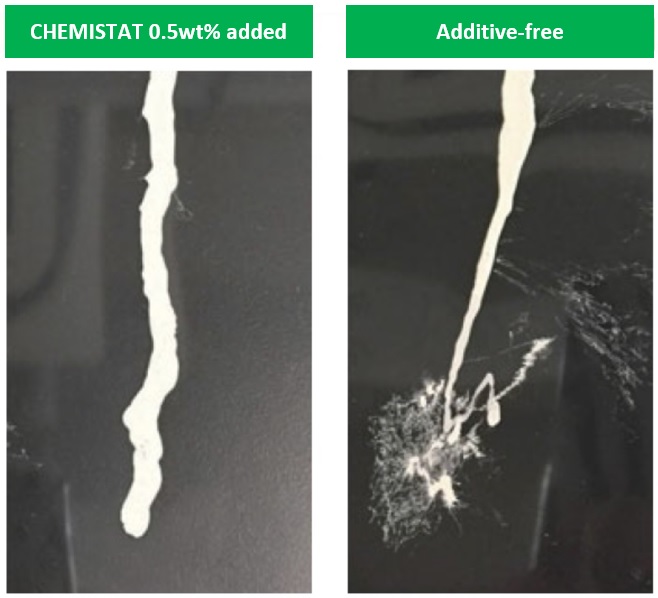

Antistatic Effect in Ink

Comparison of charging behavior of ink with and without "CHEMISTAT 3500"

Ink on PET film artificially charged by rubbing with a cloth.

Ink without additives has been blown off due to electrostatic repulsion caused by the electrification of the ink.

Main Lineup of "CHEMISTAT"

In addition to "CHEMISTAT 3500", which can be applied to paints and inks, we have a lineup of other low-molecular-weight antistatic agents.

| CHEMISTAT 3033 | CHEMISTAT 3500 | |

|---|---|---|

| Appearance | Pale yellow Granule | Pale yellow Paste |

| Solid content (%) | 99 | 97 |

| Melting point (°C) | 70 | ー |

| Ionicity | anion | anion |

| Features | Excellent heat resistance. Effective when used with high Tg resin (not suitable for transparent products). | Applicable to inks and paints |

Compatible Resins, usage

| Type | Applicable resin | CHEMISTAT 3033 | CHEMISTAT 3500 |

|---|---|---|---|

| Kneading | Poly olefin | ✔ | |

| Poly vinyl chloride | ✔ | ||

| Poly ester | ✔ | ||

| ABS | ✔ | ||

| Ink | ✔ | ||

| Positive list registration number | [B]NL-3184 | - | |

Related Information

Related products

-

Link to Sanyo Chemical's corporate website

Technology and Application Topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist