Polyolefin Wax"VISCOL", "SANWAX"

Sanyo Chemical's Polyolefin Wax

"VISCOL", "SANWAX" Performs Great in these Areas.

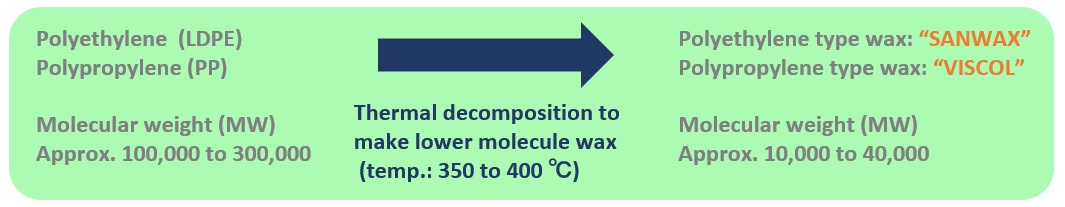

We were the first company in Japan to succeed in the industrialization of synthetic waxes. We manufacture and sell low molecular weight polypropylene ("VISCOL") and low molecular weight polyethylene ("SANWAX").

"VISCOL" and "SANWAX" have a wide molecular weight distribution unique to thermal decomposed polyolefin waxes and exhibit the following characteristics.

- Excellent pigment dispersion

- High softening point, high crystallinity

- Low viscosity, enabling improved flowability of resins and hot melt adhesives

- Low polarity and improved mold release

- Also compatible with resins other than polyolefins such as PC, ABS, PBT, etc.

"VISCOL" and "SANWAX" are Low Molecular Weight Polyolefins Obtained by Thermal Decomposition of Polyolefins.

Polyolefin Waxes "VISCOL" and "SANWAX" are

Used for the following Reasons

Pigment Dispersants

- Excellent pigment dispersibility and can enable production of high concentration masterbatches

- Moderate molecular weight has little effect on the mechanical properties of the resin

- Excellent compatibility with target resin

- Non-polar, does not interfere with pigment coloration, good color stability

Pigment Dispersants

- Low viscosity improves resin flowability

- Low polarity improves mold release properties of molded products

- Smoothness can be added to PVC

- Effective when added in small quantities and does not degrade the mechanical properties of the resin

Processability Improver for Plastics

Modifier for Paints and Printing Inks

- Wax particles form unevenness on the surface of the paint film, diffusing light and giving a matte finish.

- Prevents sedimentation of silica and other matting agents when used in combination, providing an even matting effect.

- Provides water resistance, mold resistance, and stain resistance to paint surfaces.

- Adhesion of paints and inks to hydrophobic substrates such as OPP film.

Additive for Hot Melt Adhesives

- Maintains adhesive strength at high temperatures

- Improved handling by adjusting adhesive viscosity

Features of Thermal Decomposed Polyolefin Wax "VISCOL" and "SANWAX" Products

- Good compatibility with polyolefin resins.

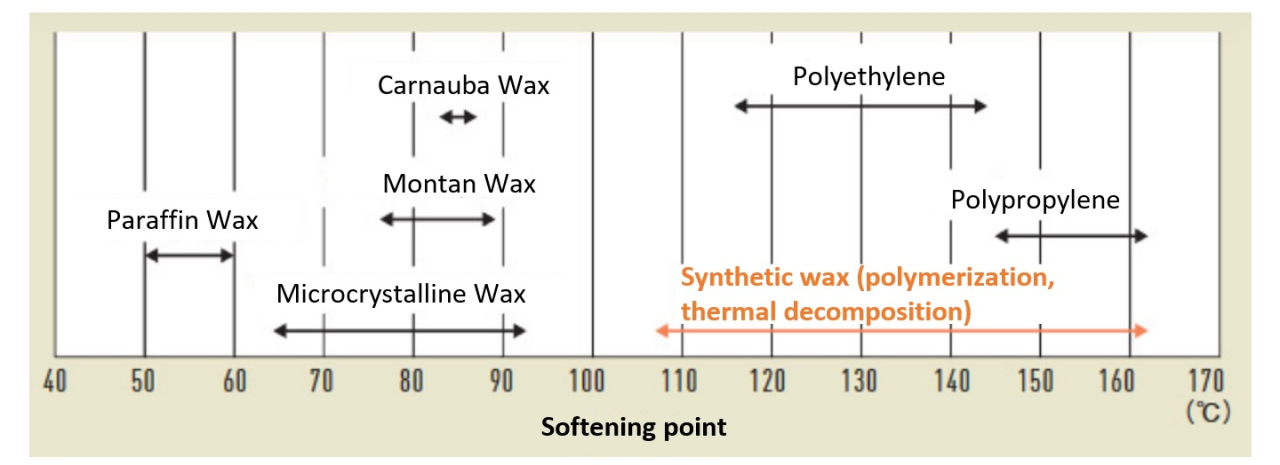

- Has the same softening point and hardness as polyolefin resins (higher softening point and higher crystallinity than natural waxes)

- It has a melt viscosity similar to natural waxes such as mineral and petroleum-based waxes.

- This is a pyrolyzed(thermally decomposed) polyolefin wax, resulting in a wide molecular weight distribution.

- Compatible with resins other than polyolefins (PC, PBT, ABS, etc.)

- The industrial process of polyolefin thermal decomposition is more suitable for small-lot production than the polymerization-type industrial process and can be finely tailored to various needs.

Comparison of Softening Points of Various Waxes

Comparison of Softening Points of Various Synthetic Waxes

| Manufacturing method | Thermally decomposed polyolefin wax (our product) | Polymerization type (high pressure) |

Polymerization type (low pressure) |

|---|---|---|---|

| Molecular weight distribution Mw/Mn |

wide |

narrow | narrow |

| Spatial structure | Contains long-chain branching | Contains short-chain branching (usually methyl group) |

Contains long-chain branching |

Sanyo Chemical's Main Lineup of Polyolefin Waxes

Main Lineup of Polypropylene Wax "VISCOL" Products

| VISCOL 330‐P |

VISCOL 440-P |

VISCOL 550-P |

VISCOL 660-P |

VISCOL |

VISCOL LM-600 (Development product) |

|

|---|---|---|---|---|---|---|

| Features | High molecular weight | Medium to high molecular weight | low molecular weight | low molecular weight | High molecular weight Low melting point |

Low molecular weight Low melting point |

| Appearance | White powder | White powder | White powder | White powder | Light yellow powder | Light yellow powder |

| APHA color scale | 200 | 200 | 200 | 1 | 1 | 1 |

| Melting point (°C) | 145 | 144 | 139 | 136 | 125 | 119 |

| Melt viscosity (mPa-s) | 4000 | 1800 | 200 | 70 | 1400 | 100 |

| Molecular weight (Mw) | 40000 | 27000 | 13000 | 10000 | 30000 | 9000 |

| Main applications | Pigment dispersants, filler dispersants, melt-flow improvers | |||||

Test procedure

Color number: Hazen method (*Gardner method), Melting point: DSC method, Melt viscosity: 160°C (*140°C), Molecular weight: High temperature GPC method

Main Lineup of Polyethylene Wax "SANWAX"

| SANWAX 161‐P |

SANWAX 131-P |

SANWAX 151-P |

SANWAX 171-P |

|

|---|---|---|---|---|

| Features | High molecular weight | Medium to high molecular weight | Low molecular weight | Low molecular weight |

| Appearance | White powder | White powder | White powder | White powder |

| APHAcolor scale | 30 | 30 | 30 | 30 |

| Melting point (°C) | 103 | 102 | 101 | 100 |

| Melt viscosity (mPa-s) |

4300 | 1000 | 290 | 180 |

| Molecular weight (Mw) | 27000 | 20000 | 13000 | 10000 |

| Main applications | Pigment dispersants, filler dispersants, melt-flow improvers | |||

Test procedure

Color number: Hazen method, Melting point: DSC method, Melt viscosity: 140°C, Molecular weight: High temperature GPC method

Data on the Effect of Adding Olefin Wax in Each Application

"VISCOL" (PP Wax), "SANWAX" (PE Wax) by Function and Target Resins

| Dispersion (mainly pigments) | Mold release | Viscosity adjustment | Lubrication | |

|---|---|---|---|---|

| Target resins Common SANWAX VISCOL |

PE PP |

EPDM | PE PP |

ABS PBT PVC PPS PC PS |

| Mechanism |

Polyolefin waxes penetrate between pigments and resins to create dispersion. |

Mold-releasing properties develop due to easy migration of polyolefin wax to the surface. | Adding low molecular weight materials improves flowability during molding. | Polyolefin waxes are less compatible with the above resins and tend to migrate to the surface, thus acting as an external lubricant. |

Application Example 1: Molding Lubricant (PVC Resin) "VISCOL"

Addition of polyolefin wax reduces resistance (torque) when PVC and stearate are melt-blended.

Test conditions

PVC : 100wt%, Stearic acid Calcium stearate: 2.5wt%, Zinc stearate: 1.0wt% , Dioctyl tin Malate polymer: 0.5wt%, Lubricant: 0.3-1.0wt Melt-kneaded using a lab-plast mill (temperature of mixer: 180°C) Mixer temperature: 180, 190, 200°C (mixer temperature: 180, 190, 200°C, screw speed: 50 rpm).

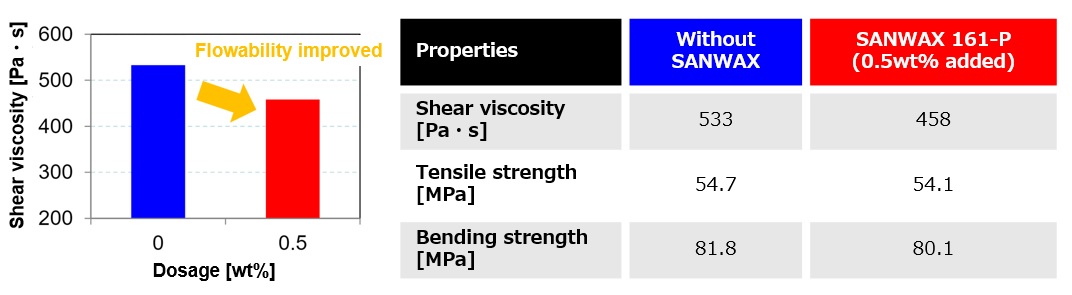

Application Example 2: Melt-flow Improver (PBT Resin) "SANWAX"

- The addition of polyolefin wax improves the melt-flow of PBT resin.

- Melt-flow inprovement is achieved with a low additive amount, which minimizes reduction in resin chemical properties

Specimen preparation conditions

Polybutylene terephthalate (PBT) resin pre-dried at 130°C for 3 hours and "SANWAX 161-P" (0.5 wt%) were mixed in a twin-screw extruder (250°C) and injection molded (molding temperature: 250°C, mold temperature: 50°C) to produce test specimens.

Test conditions

Shear viscosity: Capillary rheometer method (240°C, 608/sec) Tensile test: ASTM D638, Flexural test: ASTM D790.

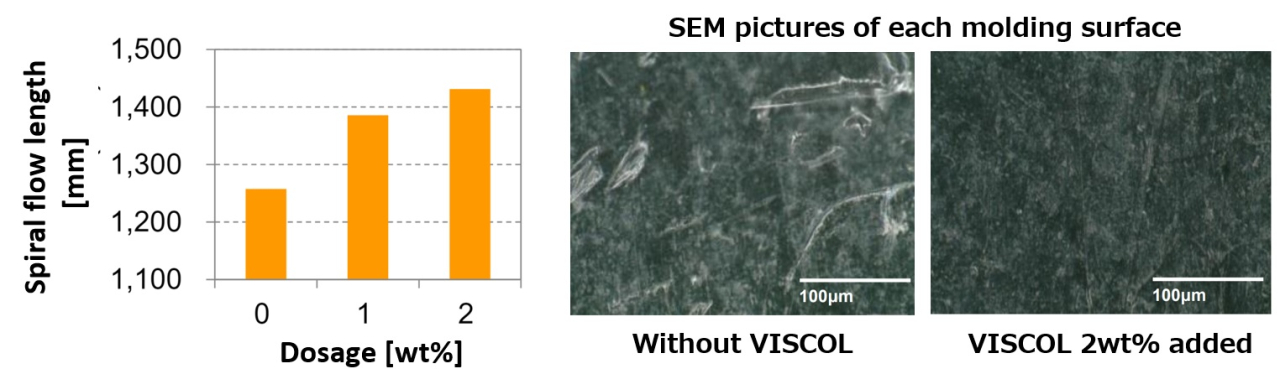

Application Example 3: Flow Improver (Long Glass Fiber/PP Composite) "VISCOL"

| Without VISCOL | VISCOL developmental product (1wt% added) | VISCOL developmental product (2wt% added) | |

|---|---|---|---|

| Spiral flow length (mm) | 1250 | 1390 | 1430 |

| Surface smoothness (Ra value)(μm) The smaller the Ra value, the smoother the surface. | 7.1 | 5.0 | 4.8 |

| Tensile strength (MPa) | 118 | 116 | 112 |

| Bending strength (MPa) | 171 | 168 | 167 |

Specimen preparation conditions

Long glass fiber/PP resin pellets (glass fiber content: 30 wt%) were dry-blended with "VISCOL" and injection molded (molding temperature: 250°C, mold temperature: 50°C) to prepare test specimens for tensile and flexural tests.

Test conditions

Spiral flow length: Long glass fiber/PP resin pellets (glass fiber content: 30 wt%) were dry-blended with "VISCOL", injected into a spiral flow mold (Archimedes spiral), and the flow length was measured. (molding temperature: 230°C, mold temperature: 50°C, injection pressure: 30 kgf/cm2, mold flow channel width: 6 mm, channel thickness: 3 mm), Surface smoothness: Ra value was measured using a laser microscope. Tensile test: ASTM D638, Bend test: ASTM D790.

Related Information

Related Products

-

Link to Sanyo Chemical's corporate website

Technology and Application Topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist