Durable hydrophilic agent for nonwoven fabrics"HYDROTHROUGH PS-887"

What is great about "HYDROTHROUGH PS-887", a durable hydrophilic agent for nonwoven fabrics

1

Realization of high repetitive water permeability to nonwoven fabrics

"HYDROTHROUGH PS-887" is a durable hydrophilic agent that imparts hydrophilicity and permeability to PP, PE, PET, and other nonwoven fabrics by coating or impregnating them with the agent.

It is a unique design by our company, and shows higher repeated water permeability in comparison to general-purpose durable hydrophilic agents.

2

Non-silicone and plant-derived ingredients are used.

It is a durable hydrophilic agent that does not contain animal oil and does not contain silicone components.

Properties of "HYDROTHROUGH PS-887"

| Item | HYDROTHROUGH PS-887 |

|---|---|

| Appearance | yellowish liquid |

| Active ingredient % | Approx. 80 |

| pH (1% emulsion) | Approx. 6.5 |

| Viscosity | Approx. 200mPa・s |

It can be supplied in the form of highly concentrated oil.

Low viscosity makes it easy to handle.

Application examples of "HYDROTHROUGH PS-887"

"HYDROTHROUGH PS-887" is used for hydrophilic treatment of hydrophobic fibers such as PP, PE, and PET nonwoven fabrics.

The following are possible applications. In addition, antistatic properties and water absorbency can be expected as functions associated with hydrophilicity improvement.

Hydrophilic treatment of nonwoven fabrics for diapers

Hydrophilic treatment of agricultural sheets

Hydrophilic treatment of nets for civil engineering

Performance of "HYDROTHROUGH PS-887"

Method of making "HYDROTHROUGH PS-887" emulsion

(Example) To produce 1000 kg of a 5% emulsion of "Hydro-Thru PS-887" with 80% active ingredient

Emulsion Preparation Method

(1) Heat a certain amount of ion exchange water to 20-40°C. (2) Emulsify PS-887 under agitation at a rate of 6-7 kg/min.

(2) Under agitation, add "HYDROTHROUGH PS-887" at a rate of 6 to 7 kg/min, and emulsify for 30 minutes (approximate).

→ Finished emulsion of 5.0% active ingredient of "HYDROTHROUGH PS-887"

Nonwoven fabric treatment method (for our evaluation)

Emulsion is applied to the nonwoven fabric so that the OPU (oil adhesion rate) is a predetermined amount, and the emulsion is dried at 50°C for 3 hours.

| Amount of brewing [kg] | |

|---|---|

| Deionized water | 937.5 |

| HYDROTHROUGH PS-887 | 62.5 |

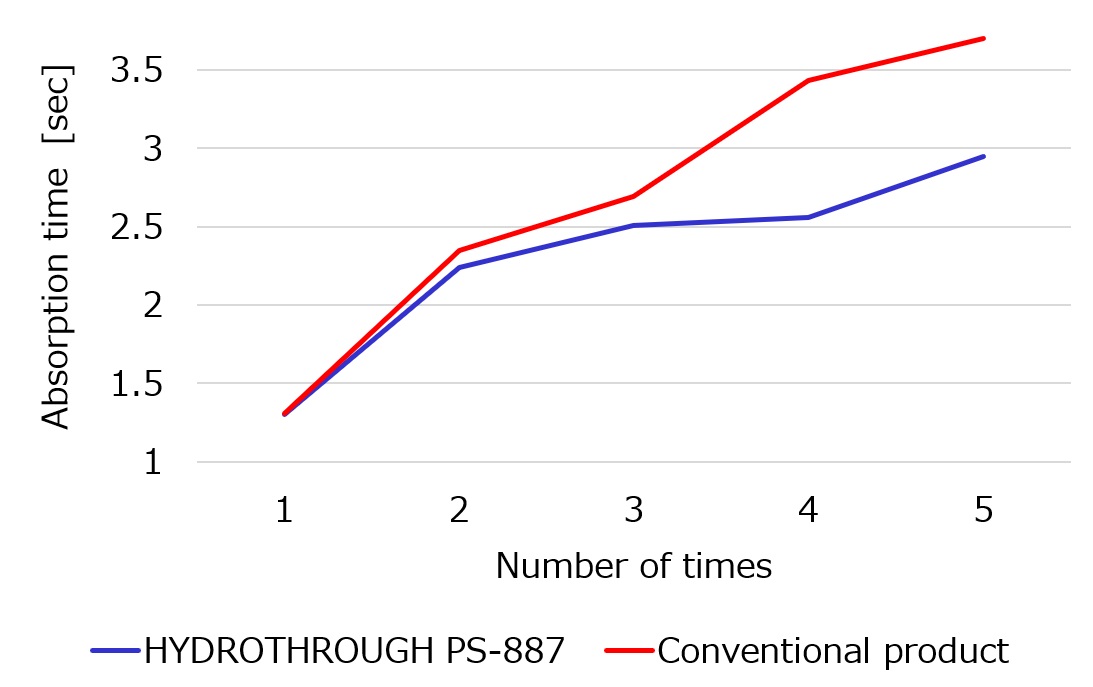

Durable hydrophilic agent (repeated permeability): Lister test

Nonwoven fabrics treated with "HYDROTHROUGH PS-887" exhibit higher repeated water permeability than conventional products.

| Absorption time [sec] | ||

|---|---|---|

| HYDROTHROUGH PS-887 | Conventional product | |

| 1st | 1.30 | 1.31 |

| 2nd | 2.24 | 2.35 |

| 3rd | 2.54 | 2.69 |

| 4th | 2.56 | 3.43 |

| 5th | 2.95 | 3.70 |

<Evaluation Method>

Follows the Repeated Liquid Strike-Through Time (EDANA WSP 70.7).

Nonwoven fabrics were placed on top of 5 sheets of absorbent paper, and the absorption time of 5 ml of saline solution was measured using a Lister tester (shown below).

The same method is repeated at 1-minute intervals for the second and subsequent times.

<Rating Condition>

Evaluated with OPU (oil pigmentation rate) = approx. 0.5%, PP/PE core sheath air-through non-woven fabric = 23gsm

Fig. Appearance of Lister tester

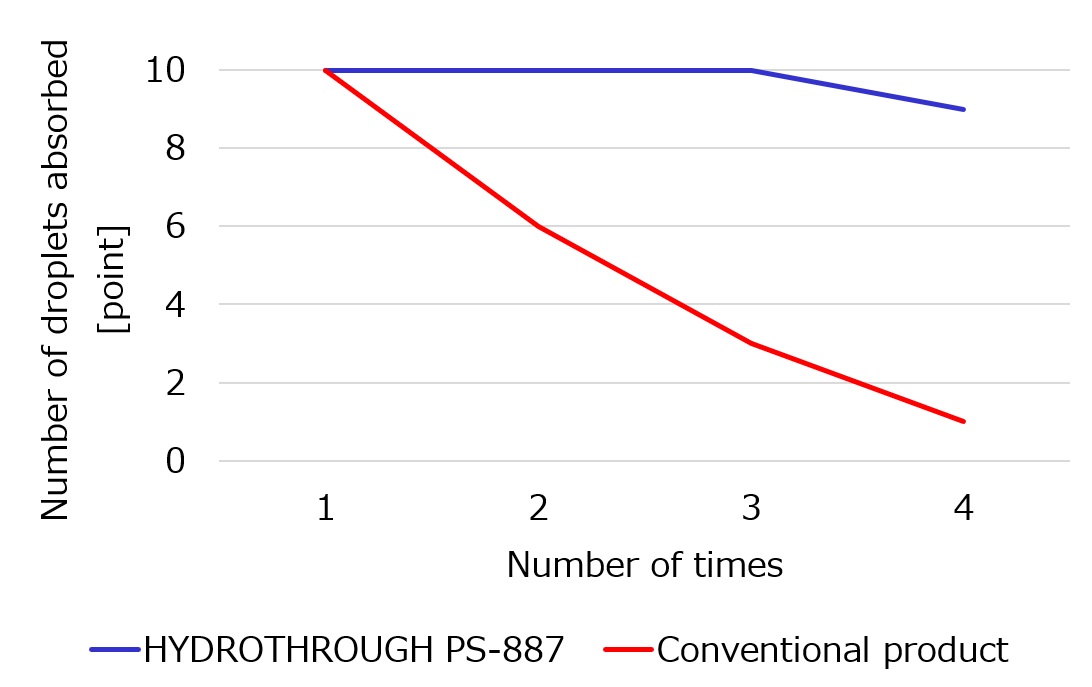

Durable hydrophilic agent (repeated permeability): 10-point method

Nonwoven fabrics treated with "HYDROTHROUGH PS-887" exhibit higher repeated water permeability than conventional products in the following evaluation methods.

| Number of droplets absorbed [points/10points] |

||

|---|---|---|

| HYDROTHROUGH PS-887 | Conventional product | |

| 1st | 10 | 10 |

| 2nd | 10 | 6 |

| 3rd | 10 | 3 |

| 4th | 9 | 1 |

Evaluated with OPU (oil pigmentation rate) = approx. 0.5%, PP/PE core sheath air-through non-woven fabric = 23gsm

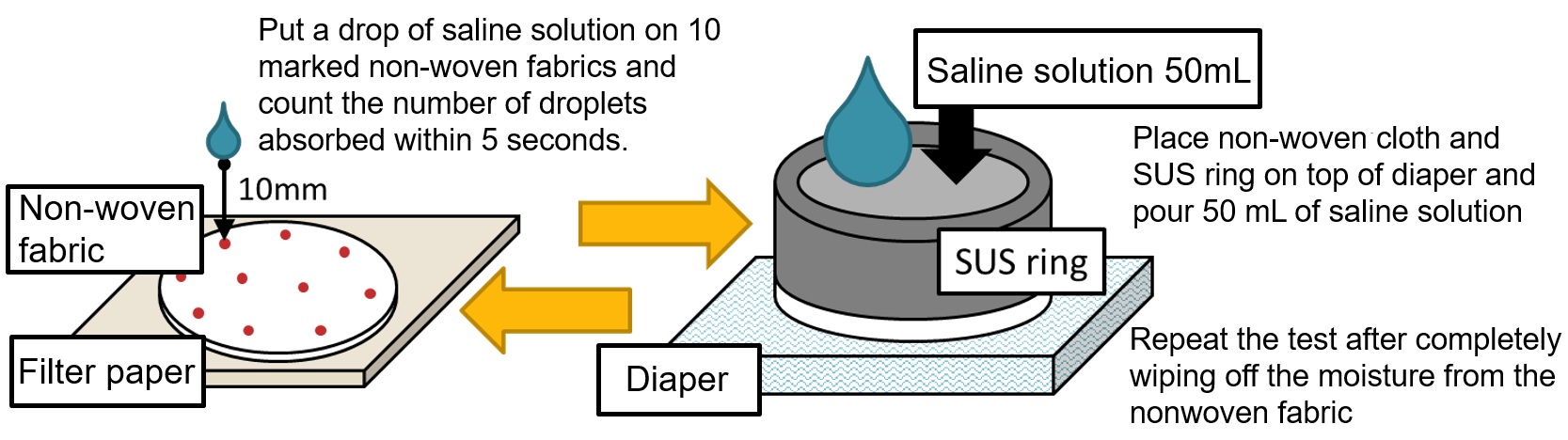

<Evaluation method>

Put a drop of saline solution on the 10 marked non-woven fabrics, and count the number of drops absorbed within 5 seconds.

Place the non-woven cloth and SUS ring on the diaper and pour 50 mL of saline solution.

Wipe off the water completely from the non-woven cloth, and repeat the test.

<Rating condition>

Evaluated with OPU (oil pigmentation rate) = approx. 0.5%, PP/PE core sheath air-through non-woven fabric = 23gsm

Fig. Repeated Permeability Test Method

Note that the liquid return property (pressurized return water volume) is slightly larger than that of the general-purpose product because the durable hydrophilicity is improved when non-woven fabrics are treated with "HYDROTHROUGH PS-887".

Spot absorbency: Run off test

Nonwoven fabrics treated with "HYDROTHROUGH PS-887" show comparable spot absorbency compared to general-purpose products.

| HYDROTHROUGH PS-887 [mm] |

Conventional product [mm] |

|

|---|---|---|

| Liquid flow distance | 13 | 14 |

Evaluated with OPU (oil pigmentation rate) = approx. 0.5%, PP/PE core sheath air-through non-woven fabric = 23gsm

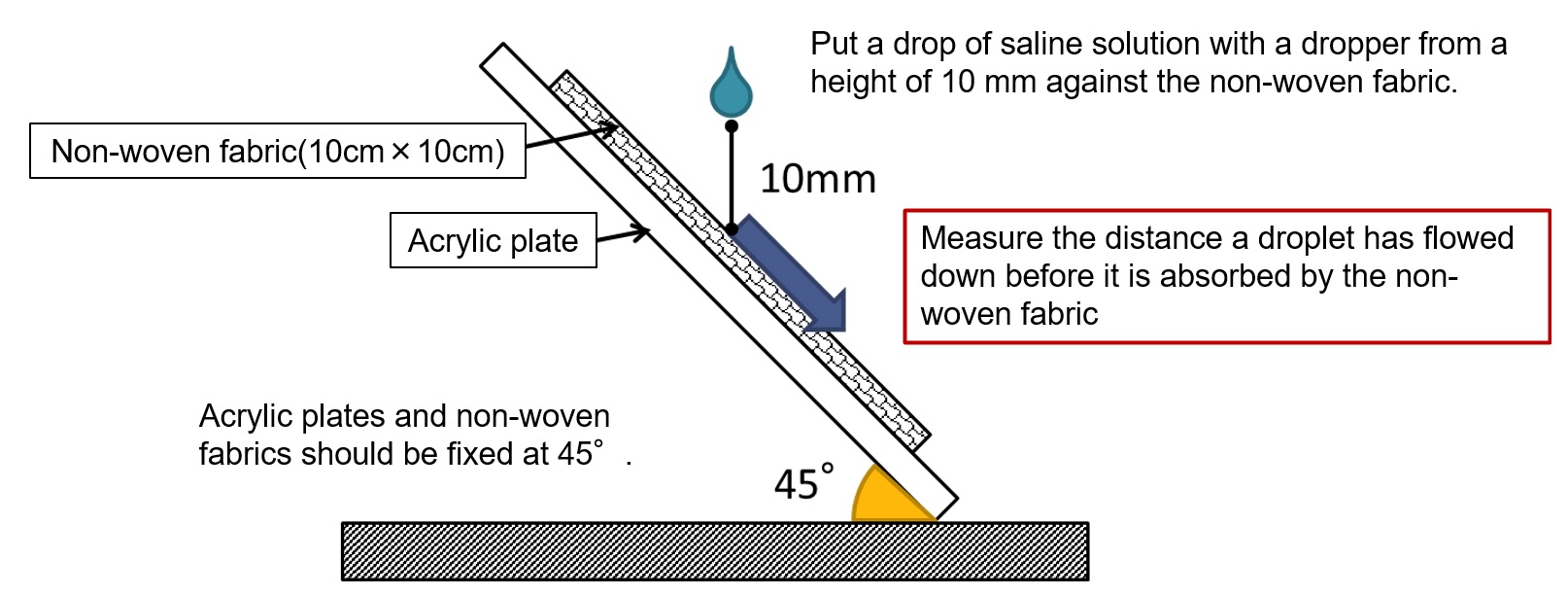

<Evaluation Method>

Put a dropper droplet of saline solution from a height of 10 mm against the non-woven fabric.

Measure the distance the droplet flowed down to be absorbed into the nonwoven fabric.

Fig. Run Off test method

Before handling this product, be sure to read the "Safety Data Sheet" (SDS) for this product and its sub-materials (chemicals).

Related Information

Related Products

-

Link to Sanyo Chemical's corporate website

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist.