Permanent Antistatic Agents (General Purpose)"PELESTAT"

Prevention of Spark and Dust Adhesion for Various Plastic Products by Simply Mixing with a Permanent Antistatic Agent.

What's great about Sanyo Chemical's Permanent Antistatic Agent "PELESTAT"

1

Full Lineup for Various Resins and Molding Methods

When added to various resins such as ABS, PP, and PE, it quickly exhibits antistatic performance and permanently prevents problems caused by static electricity.

2

Low Pollution

Since "PELESTAT" is an ion-conductive polymer, there is no contamination of the resin surface due to bleed-out of antistatic agents.

3

Retention of Mechanical Properties

Minimizes the effect on hardness and heat resistance of plastics when added. While imparting an antistatic effect, there in almost no change in mechanical properties.

"PELESTAT" is Used to Solve Various Static Electricity Problems

It can be used to solve various static electricity problems, from preventing dust and powder from adhering to resin surfaces to explosion-proof applications.

Prevents Adhesion of Dust and Powder (Surface Resistivity: 1012 (Ω/sq.))

<Mainly Applied to Home Appliance Parts and Automobile Interior Parts>

Vacuum Cleaner Dust Box

Base Resin: Transparent ABS

(Injection Molding)

When added to a transparent dust box, it prevents dust adhesion caused by static electricity buildup on the resin surface, while maintaining transparency and visibility.

Refrigerator Parts

Base Resin: PP

(Injection Molding)

Prevents dirt from accumulating on the floor near the refrigerator scaffolds.

Air Conditioners, Air Cleaner Front Cover

Base Resin: HIPS

(Injection Molding)

Prevents stains caused by dust adhesion.

Medical Equipment (Inhalers)

Prevents powder from adhering to the inner wall due to static electricity, contributing to an accurate drug dosage.

Prevention of Sudden Discharge (Surface Resistivity: 1010 to 1011 (Ω/sq.)) <Applied Mainly for Explosion-proof Applications >

Explosion-proof helmet

Base resin: PP (injection molding)

They are also used in explosion-proof applications for plastic products because they suppress the generation of sparks caused by static electricity.

Flexible Container Pack for Powder (inner bag)

Base Resin: PE

(Inflation Molding)

Antistatic inner bags reduce the risk of dust explosions.

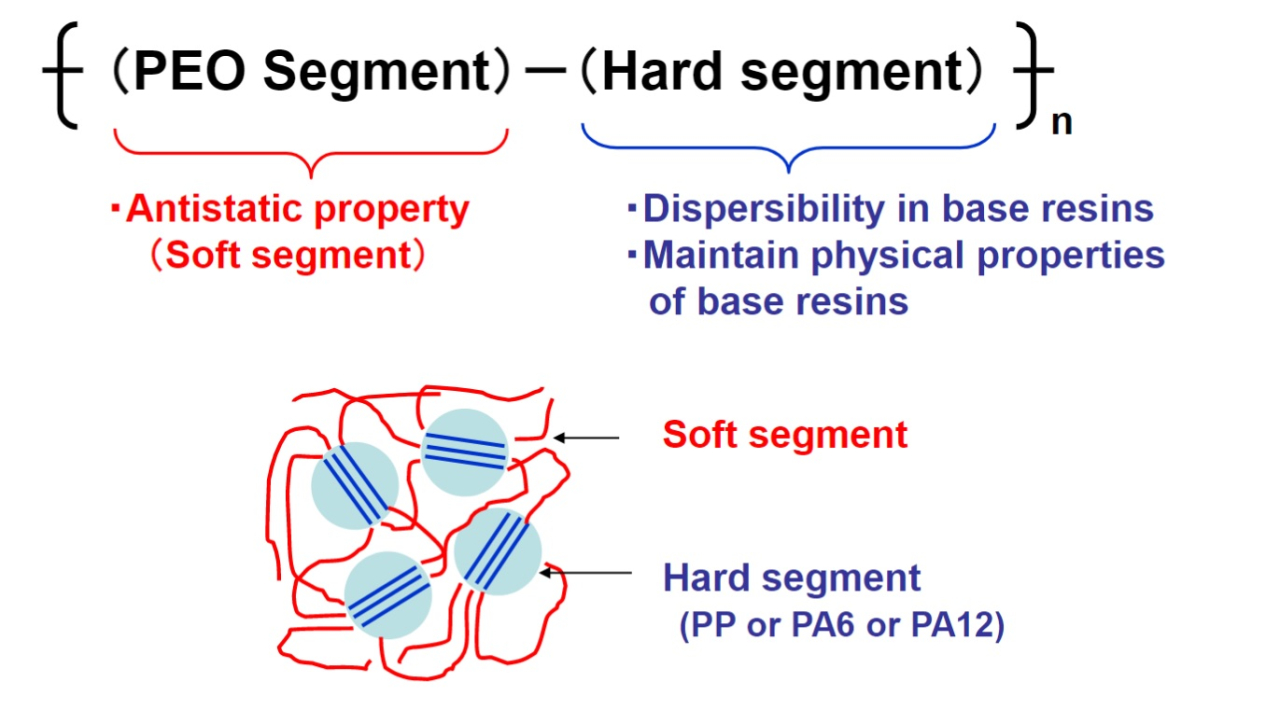

Features of Sanyo Chemical's Permanent Antistatic Agent "PELESTAT" Products

Sanyo Chemical's Antistatic Agent "PELESTAT" can Solve Static Electricity Problems in Plastic Products with the following Features.

1

Good Dispersibility

The addition of this product provides antistatic properties with almost no change to mechanical properties.

2

Superiority over Carbon-based Conductive Materials

It has advantages over carbon-based conductive materials in homogeneous antistatic properties, low dust generation, impact resistance, and color selectivity.

3

Superiority over Low-molecular-weight Antistatic Agents

It is superior to low-molecular-weight antistatic agents in that it has a long-lasting antistatic effect, is independent of humidity, and exhibits antistatic properties immediately after molding.

4

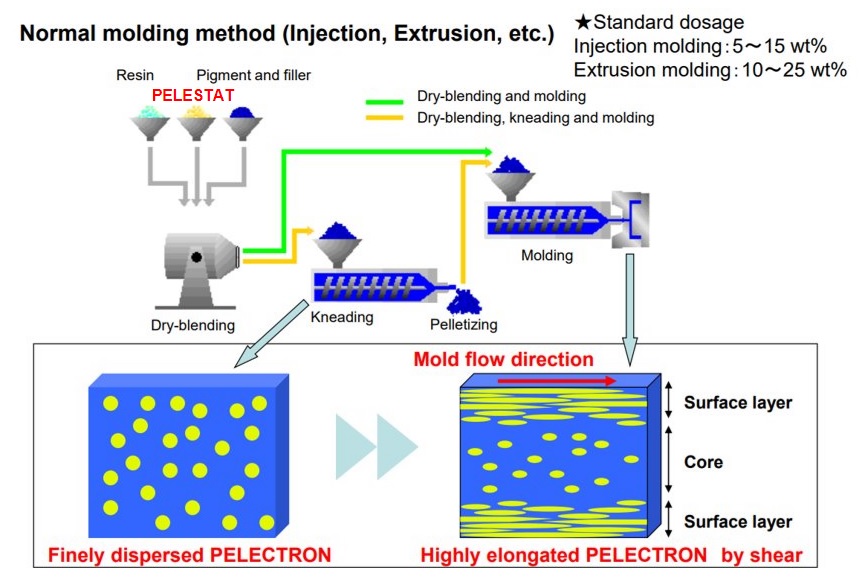

Various Process Compatibility and Technical Support

Various molding methods such as injection molding, extrusion molding, etc. are available.

We can provide technical support based on our extensive experience.

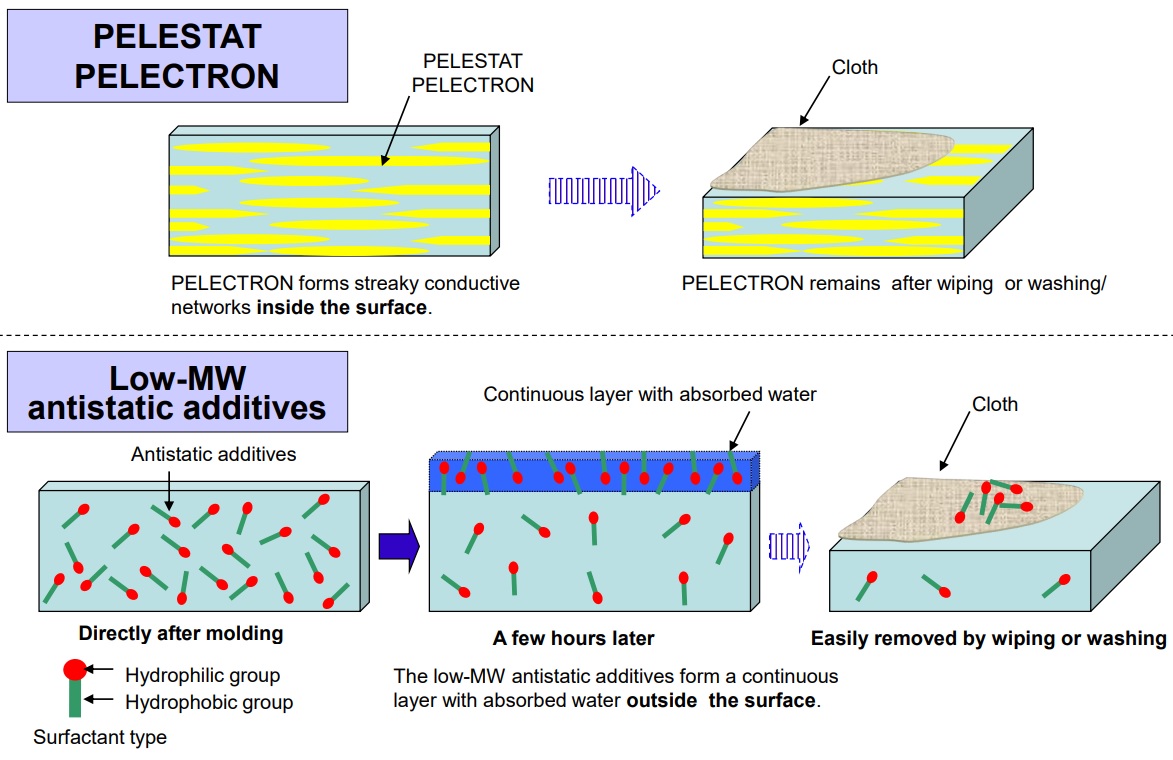

Permanent Antistatic Agent "PELESTAT"/"PELECTRON" vs. Low Molecular Weight Antistatic Agents

| Permanent antistatic agent PELESTAT PELECTRON |

Low-molecular-weight antistatic additives | |

|---|---|---|

| Surface resistivity (Ω/sq.) |

108~1012 |

109~1012 |

| Required additive amount (wt%) | 5~25 | 0.2~2 |

| Sustainability of antistatic effect | Good (Sustained) |

Poor (Not sustainable) |

| Humidity dependence of antistatic effect | Good (No humidity dependence) |

Poor (Worse under low humidity) |

| Antistatic properties immediately after resin molding | Good (Effective immediately after molding) |

Poor (No effect immediately after molding) |

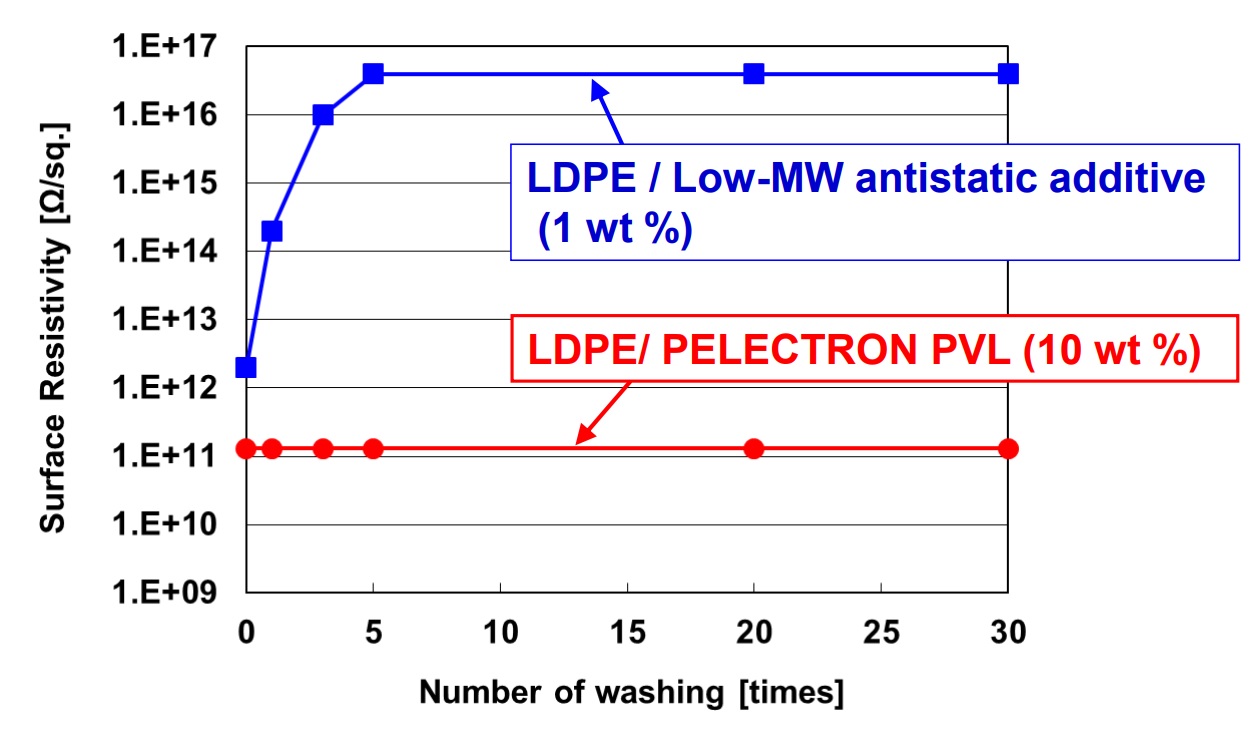

Example of Evaluation of Maintaining Antistatic Properties

When LDPE containing a low molecular weight migratory type antistatic agent is washed, the antistatic effect wears off. In the case of a permanent antistatic agent, the surface resistivity does not change even after repeated washings.

Measurement method

Test pieces of LDPE resin were soaked in water, rinsed with a cotton cloth on the surface of the test piece, and then dried under reduced pressure (130 Pa, 70ºC, 2 hours). The test piece was then humidified for 24 hours at 23ºC, 50% R.H., and the surface resistivity was measured using an ultra-insulation meter.

LDPE resin: extrusion grade used [MFR = 2 g/10min (190ºC, 21.18 N)

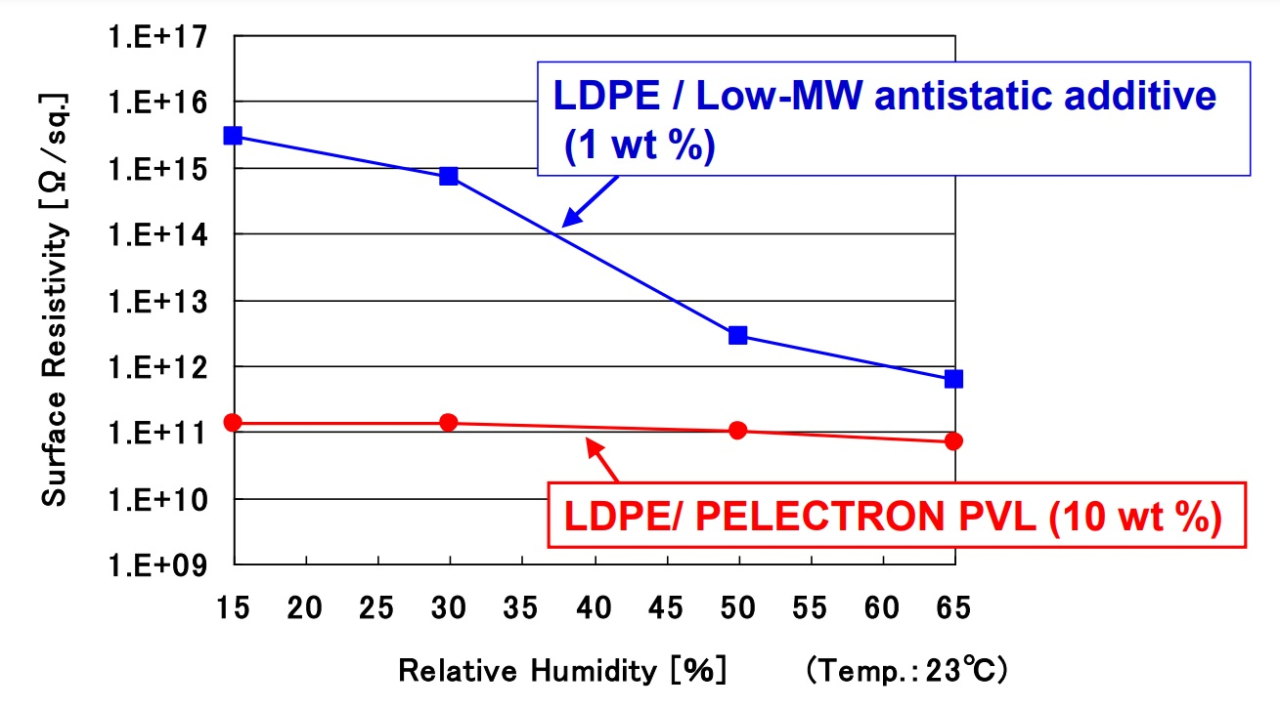

Example of Evaluation of Humidity Dependence of Antistatic Effect

The surface resistivity of LDPE resin with a low molecular weight antistatic agent increases at low humidity, whereas the surface resistivity of LDPE resin with permanent antistatic agent does not change with humidity.

Measurement method

Test pieces of LDPE resin were placed in a room with a specific humidity at 23ºC for 24 hours, and then surface resistivity was measured using an ultra-insulation meter.

LDPE resin: extrusion grade used [MFR = 2 g/10min ( 190ºC , 21.18 N)

Comparison of Permanent Antistatic Agent "PELESTAT"/ "PELECTRON" and Carbon-based Conductive Materials

| Permanent antistatic agent PELESTAT PELECTRON |

carbon black | carbon fiber | |

|---|---|---|---|

| Conductor (elec) | ionic conduction | electron conduction | electron conduction |

| Surface resistivity(Ω/sq.) |

~109 |

~106 | ~106 |

| Resistance uniformity | Very Good | Fair | Poor |

| Prevention of dust attraction | Very Good | Poor | Fair |

| Stiffness (bending modulus) | Fair | Good | Very Good |

| Impact resistance | Very Good | Poor | Fair |

| Color selectivity | Very Good | Poor(black only) | Poor(black only) |

Main Lineup of Permanent Antistatic Agent "PELESTAT"

| PELESTAT 300 | PELESTAT 230 | PELESTAT NC6321 | PELESTAT 6500 | PELESTAT 6200 | |

|---|---|---|---|---|---|

| Target resin | PP、PE (Injection molding) | PP、PE | ABS、 Clear ABS、PC/ABS PBT | ABS、 Clear ABS、PC/ABS PBT | ABS、PC/ABS PBT |

| Appearance | Pale yellow pellet | Pale yellow pellet | Pale yellow pellet | Pale yellow pellet | Pale yellow pellet |

| Melting point ℃ | 135 | 163 | 203 | 191 | 193 |

| MFR g/10min (Measurement temperature) | 30 (190℃) | 10 (190℃) | 20 (215℃) | 20 (215℃) | 30 (215℃) |

| Surface resistivity* Ω/□ | 1×108 | 5×107 | 1×109 | 1×108 | 1×108 |

| Surface resistivity of molded product can be controlled (Ω/□) | 1010~1012 | 1010~1012 | 1010~1012 | 1010~1012 | 1010~1012 |

*The surface resistivity of "PELESTAT" was measured using a super-insulation tester after molding "PELESTAT" alone and humidifying it at 23°C 50%R.H. for 24 hours.

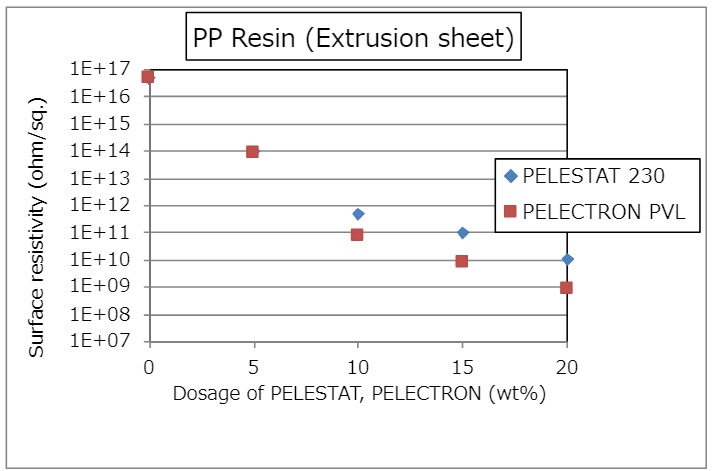

Additional Data for Resins

PP Resins (Extrusion Sheet)

"PELESTAT 230" (General Purpose),

"PELECTRON PVL" (Low Resistance)

Resin grade : Film type , MFR=3.3(g/10min) [230℃, 21.18N]

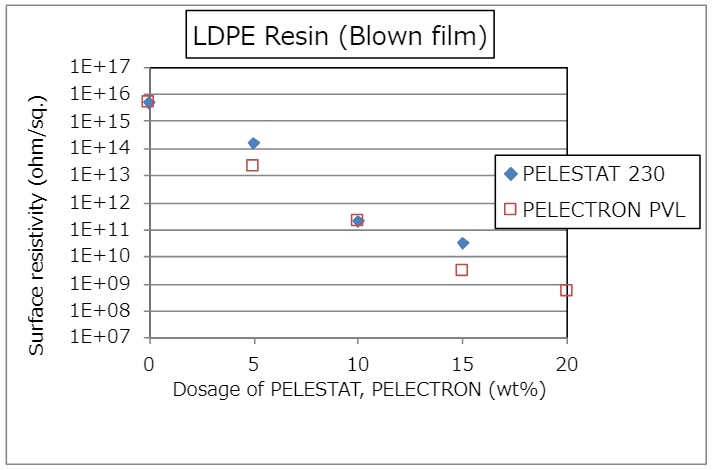

LDPE Resin (Blown Film)

"PELESTAT 230" (General Purpose),

"PELECTRON PVL" (Low Resistance)

Resin grade : Film type , MFR=0.3(g/10min) [190℃, 21.18N]

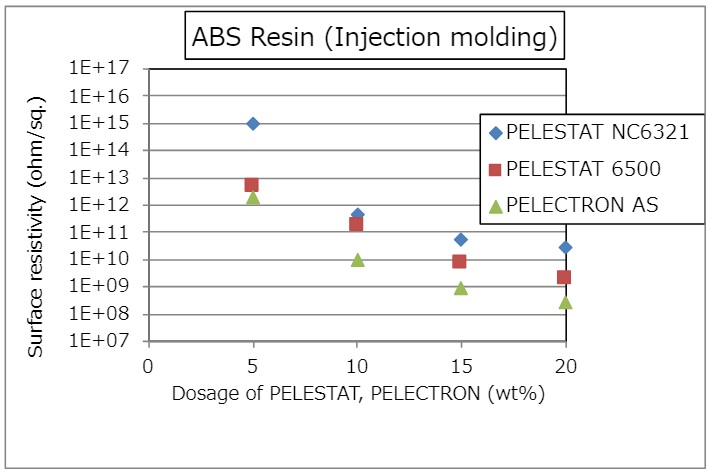

ABS Resin (Injection Molding)

"PELESTAT NC6321" (General Purpose), "PELESTAT 6500" (General Purpose), "PELECTRON AS" (Low Resistance)

Resin grade : General / high impact type , MFR=17(g/10min) [220℃, 21.18N]

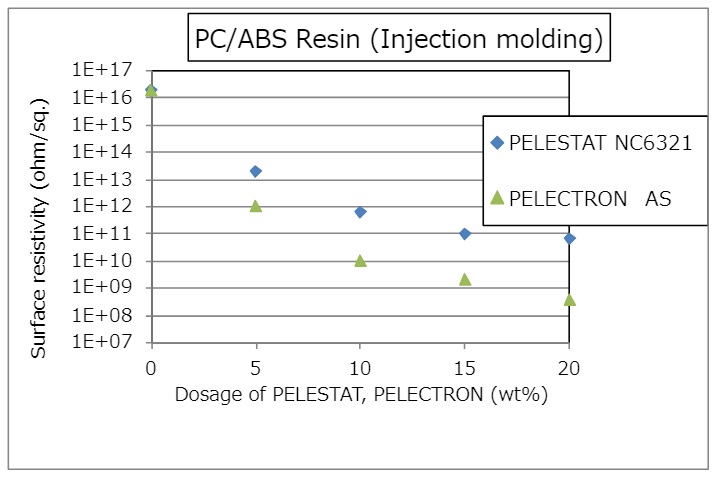

PC/ABS Resins (Injection Molding)

"PELESTAT NC6321" (General Purpose) , "PELECTRON AS" (Low Resistance)

Resin grade : General / high impact type , MFR=7.2(g/10min) [260℃, 21.18N]

Related Information

Related Products

-

Link to Sanyo Chemical's corporate website

Technology and Application Topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist