Filler Dispersant in Resin (Acid-modified PP)"UMEX"

Acid-modified Polypropylene for Various Applications from Biomass Dispersion to Compatibilization of Polymer Alloys

What's Great about Sanyo Chemical's "UMEX" (Acid-modified Polypropylene)

1

Wide Range of Acid Values

We have a wide range of acid modified polyolefins with various degrees of acid modification, and can recommend the most suitable grade for your application, from dispersion of filler in resins to flowability improvement and softening point adjustment of hot-melt adhesives.

2

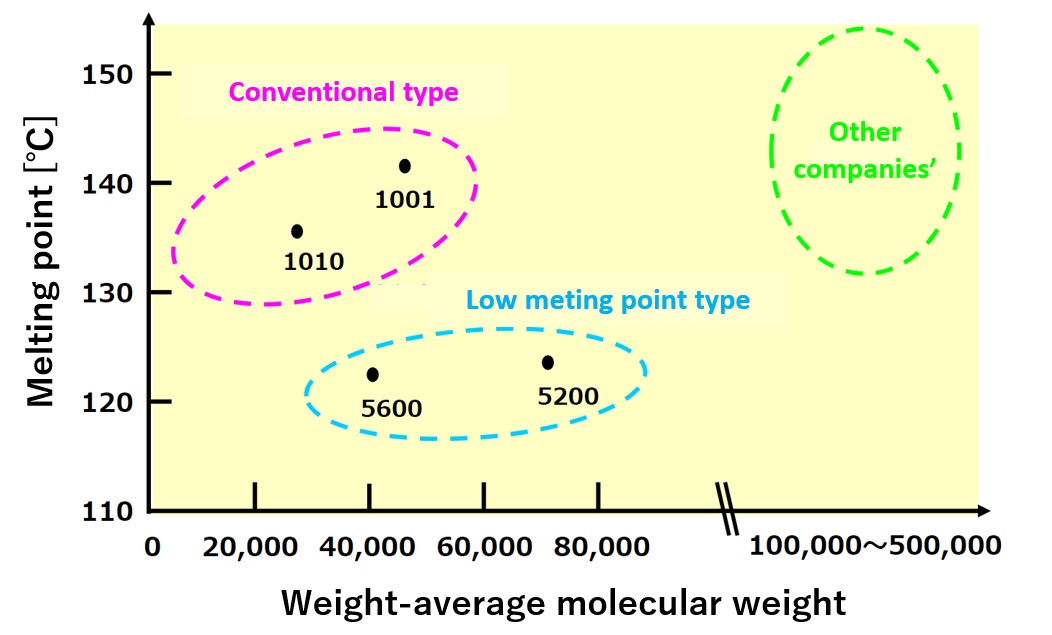

Low Molecular Weight Design Achieves High Fluidity

Compared with acid modified polyolefins from other companies, the molecular weight of Sanyo Chemical's acid modified polyolefin "Umex" is designed to be lower, enabling more effective flowability during resin melting.

3

Melting Point Valuation

We offer a variety of acid modified polyolefins from high to low melting point types, depending on the purpose and application.

"UMEX" is a highly modified polyolefin modified with maleic anhydride, a functional group (maleic anhydride) added to a low molecular weight polyolefin obtained by thermal decomposition of polyolefin resin.

Why is Acid-modified PP Important in Biomass Composites?

In recent years, there has been a trend to reduce the use of petroleum-derived raw materials by blending biomass as a filler in resins. Such biomass composite materials also contribute to the environment in terms of effective utilization of by-products.

- Examples of Biomass fillers

- Plastic mixed with wood powder: Materials for housing construction and wooden decks

- Rice bran: Used for garbage bags and food storage bags

Challenges in Dispersibility of Biomass Fillers

Because of the opposing properties of biomass (hydrophilic) and plastics (hydrophobic), uniform mixing of biomass into plastic tends to be poor, and simply mixing the two does not have a sufficient dispersion.

Challenges in Formability of Biomass Fillers

Simply mixing biomass filler into resin results in a material that is difficult to process with poor moldability, resulting in low yield and poor appearance of the molded product.

The dispersibility and moldability of biomass filler dispersion resin can be improved by adding Sanyo Chemical's acid modified polypropylene, "UMEX", to biomass composites during mixing.

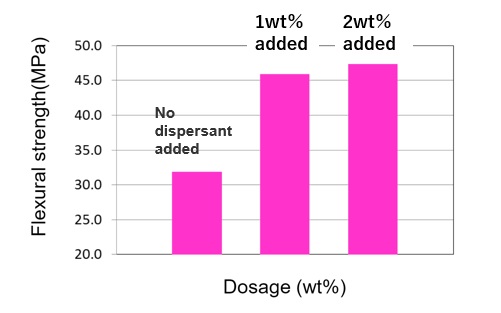

The mechanical properties of wheat bran/PP resin composites are improved by the addition of Sanyo Chemical's acid-modified PP, "UMEX".

| Properties | No addition | UMEX 1001 (1wt% added) | UMEX 1001 (2wt% added) |

|---|---|---|---|

| Tensile strength (MPa) | 17 | 27 | 28 |

| Bending strength (MPa) | 32 | 46 | 47 |

| Flexural modulus (GPa) | 2.0 | 2.2 | 2.3 |

Specimen preparation conditions

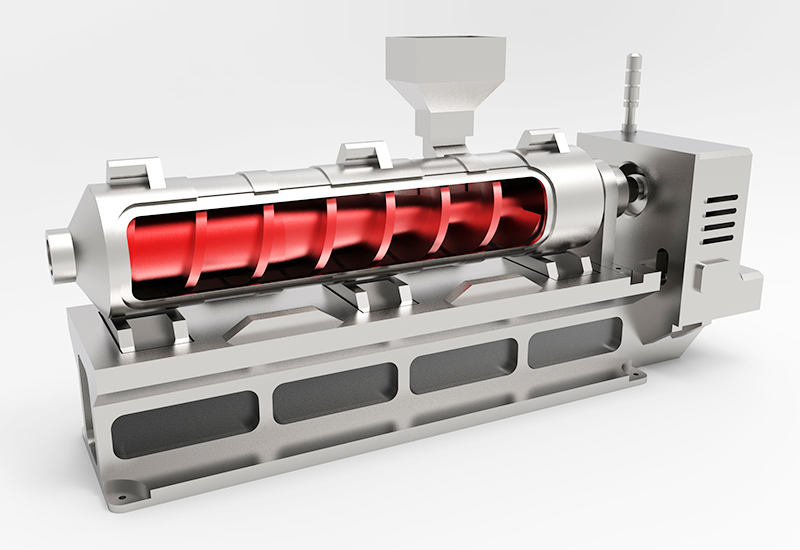

Wheat bran(50wt%)*, polypropylene resin (50wt%), and Umex were melted and kneaded in a twin-screw extruder (200°C) to produce resin test pieces using an injection molding machine. (Molding temperature: 200°C, mold temperature: 50°C) *Wheat dander: average particle size 180 μm, pre-dried (80°C, 2 hours), used.

Test conditions

Bending test: ASTM D790, Tensile test: ASTM D638, Izod impact test: JIS K7110 (notched).

Features of the Acid-Modified Polyolefin "UMEX"

- "UMEX" is an acid modified polypropylene with high degree of modification and low melt viscosity, which improves the dispersibility of pigments and fillers in polyolefin resins.

- Provides dispersibility and compatibility: High degree of acid denaturation and low additive amount provides filler dispersion effect in resin.

- Improved flowability: Low melt viscosity, excellent for improving the moldability of resins.

- Improved heat resistance: High softening point provides excellent heat resistance improvement.

Acid-modified PP "UMEX" is Used for the Following Reasons

1

Dispersants for Biomass Composites and Pigments

The addition of "UMEX" improves the dispersibility of wood flour and other biomass materials in PP resin and increases the mechanical strength of the composite material.

2

Compatibilizer for Polymer Alloys

The addition of "UMEX" improves the compatibility of polypropylene and nylon resins.

3

Flow Improver for ABS Resin

"UMEX" is compatible with ABS resins, and its addition improves flowability.

4

Softening Point Adjuster for Hot Melt Adhesives

The desired softening point can be adjusted by adding to hot melt adhesives.

5

Dispersant of Glass Fiber and Carbon Fiber in Resin

The addition of "UMEX" improves the mechanical properties of glass fiber/PP composites, such as bending strength. The same effect is achieved when carbon fibers are dispersed in PP resin.

Main Lineup of Sanyo Chemical's Acid-modified PP "UMEX"

| UMEX 1001 | UMEX 1010 | UMEX 100TS | UMEX 5200 | UMEX 5600 (developmental product) | |

|---|---|---|---|---|---|

| Main application | Glass fiber/resin dispersant | Wood flour/resin dispersant | Hot melt adhesives Asphalt additives | Glass fiber/resin dispersant | Glass fiber/resin dispersant |

| Apearance | yellow granular | yellow granular | yellow granular | yellow granular | yellow granular |

| Melting point ℃ | 142 | 135 | 136 | 124 | 122 |

| Melt viscosity mPa・s | 15000 | 6000 | 120 | 20000 | 3000 |

| Acid value mgKOH/g | 26 | 52 | 3.5 | 11 | 17 |

| Moleular weight MW | 45000 | 30000 | 9000 | 70000 | 40000 |

Relationship between Molecular Weight and Melting Point of the "UMEX"

Its low molecular weight results in low melt viscosity, and its addition improves the flowability of the resin during molding.

Relationship between Molecular Weight and Acid Value in "UMEX"

"UMEX" has a high degree of acid modification and a filler dispersion effect in resins at low additive amounts.

Data on the Effect of Adding "UMEX" in each Application

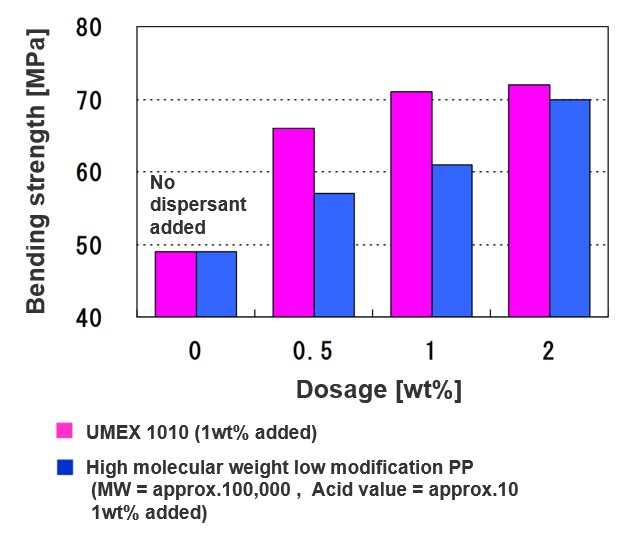

Application Example 1: Biomass Composite Material (Wood Powder/PP Resin) "UMEX 1010"

The addition of "UMEX" improves the mechanical properties of wood flour/PP composites, such as bending strength.

The addition of "UMEX" improves the mechanical properties of wood flour/PP composites.

Compared to high molecular weight low modification PP. The mechanical property improvement effect can be obtained with a lower additive amount.

| Properties | No dispersant added | UMEX 1010 (1wt% added) | High molecular weight low modification PP (1wt% added) |

|---|---|---|---|

| Bending strength (MPa) | 49 | 71 | 61 |

| Tensile strength (MPa) | 28 | 47 | 38 |

| Izod impact strength (kJ/m2) | 2 | 2 | 2 |

Specimen preparation conditions

Wood flour (50wt%)*, polypropylene resin (50wt%), and "UMEX" were melted and kneaded in a twin-screw extruder (200°C) to make resin specimens using an injection molding machine. (Molding temperature: 200°C, mold temperature: 50°C) * Wood flour: Cedar wood flour with an average particle diameter of 180 μm was dried in a progressive air dryer (80°C, 2 hours) and used.

Test conditions

Bending test: ASTM D790, Tensile test: ASTM D638, Izod impact test: JIS K7110 (notched).

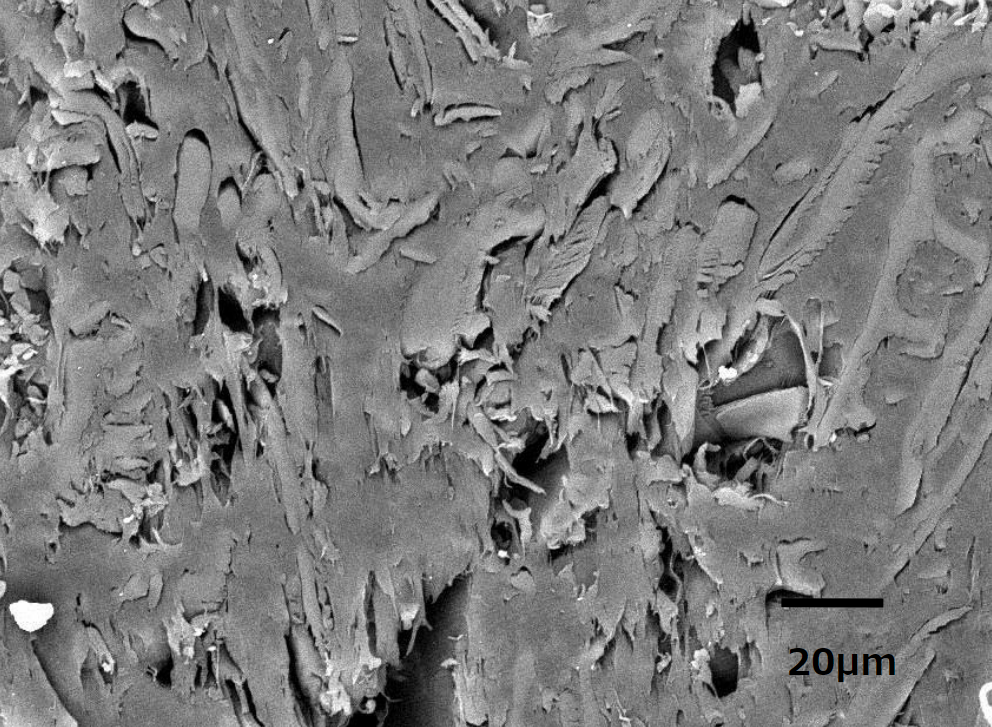

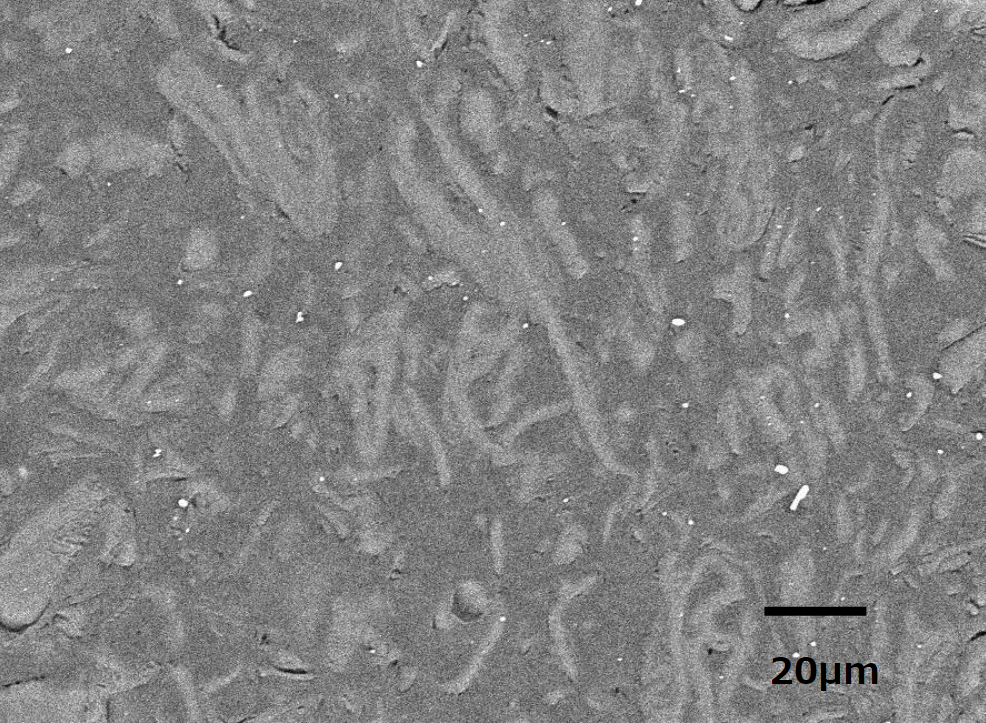

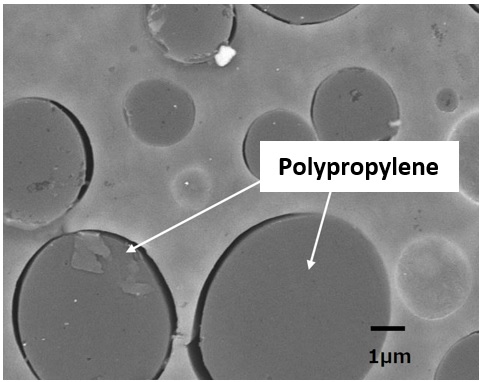

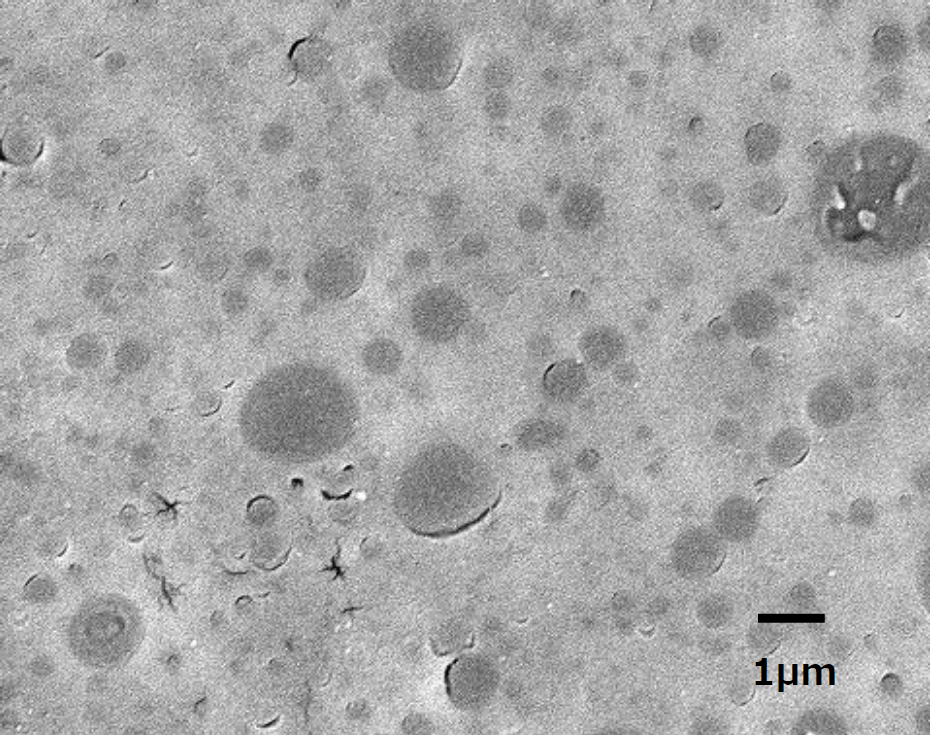

SEM image of cross section of biomass composite material (wood powder/PP resin)

No "UMEX" added

Addition of "UMEX 1010"(1wt%)

The addition of "UMEX" improves adhesion at the interface between wood flour and polypropylene resin.

Application Example 2: Glass Fiber Dispersant (Glass Fiber/PP Resin)

"UMEX 1001"

The addition of ”UMEX” improves the mechanical properties such as the bending strength of PP resin with glass fiber dispersion.

Addition of "UMEX 1001" (0.5 to 5 wt%) improves flexural strength

Improves mechanical properties at lower additions compared to high molecular weight low modification PP

| Properties | No dispersant added | UMEX 1001 (1wt% added) | High molecular weight low modification PP (1wt% added) |

|---|---|---|---|

| Bending strength (MPa) | 50 | 120 | 80 |

| Tensile strength (MPa) | 27 | 72 | 70 |

| Izod impact strength (kJ/m2) | 9 | 11 | 8 |

Specimen preparation conditions

Polypropylene resin (70wt%), glass fiber (30wt%)*, and a dispersant were melted and kneaded in a twin-screw extruder at 220°C. Resin specimens were prepared using an injection molding machine. (Molding temperature: 220°C, mold temperature: 50°C) *Glass fiber: chopped strand with fiber diameter = 13 μm and fiber length = 3 mm

Test conditions

Bending test: ASTM D790, Tensile test: ASTM D638, Izod impact test: JIS K7110 (notched).

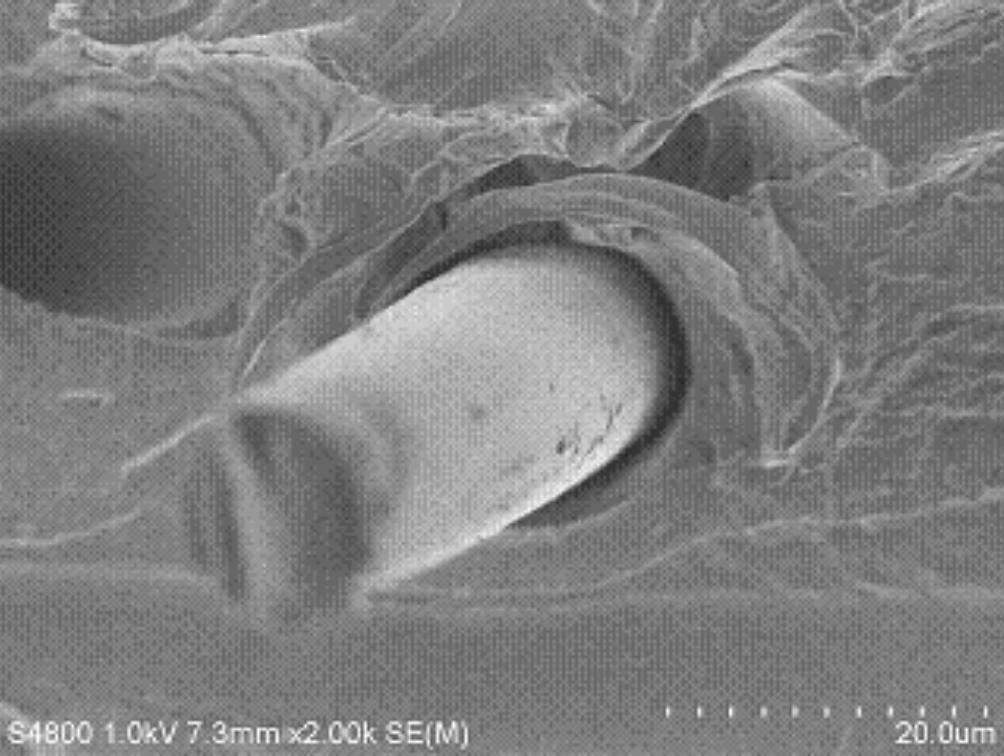

Glass fiber dispersion (glass fiber/PP resin) SEM image of cross section

No "UMEX" added

Addition of "UMEX 1001" (1wt%)

The addition of "UMEX" improves adhesion at the interface between the glass fiber and polypropylene resin.

Application Example 3:

Compatibilizer for Alloys (PP Resin/nylon Resin) "UMEX 1001"

The addition of "UMEX" improves the tensile strength and other mechanical properties of nylon and PP resin alloys.

| Properties | No dispersant added | UMEX 1001 (2wt% added) |

|---|---|---|

| Bending strength (MPa) | 40 | 45 |

| Tensile strength (MPa) | 58 | 62 |

| Izod impact strength (kJ/m2) | 4 | 4 |

Specimen preparation conditions

6-nylon (70 wt%), polypropylene resin (30 wt%), and Umex were melt-mixed in a twin-screw extruder (240°C), and resin specimens were prepared using an injection molding machine. (Molding temperature: 240°C, mold temperature: 50°C)

Test conditions

Bending test: ASTM D790, Tensile test: ASTM D638, Izod impact test: JIS K7110 (notched).

SEM image of cross section of PP resin/nylon resin alloy

No "UMEX" added

Addition of "UMEX" 1001 (2wt%)

The addition of "UMEX" improves the compatibility of nylon and polypropylene resins.

Related Information and Topics

Related Products

-

Additive for resin

-

Link to Sanyo Chemical's corporate website

Technology and Application Topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist