Polycarboxylic acid type pigment dispersant"CARRYBON L-400"

What's great about Sanyo Chemical's polycarboxylic acid dispersant "CARRYBON L-400"

1

Excellent dispersibility of inorganic pigments in water

"CARRYBON L-400" has excellent dispersibility in water of various inorganic pigments such as calcium carbonate, clay, satin white, and aluminum hydroxide, and when used to disperse them, it produces a slurry with low viscosity.

2

Dispersant with good thermal stability

Pigment slurries using "CARRYBON L-400" as a dispersing agent have excellent viscosity stability when heated, so problems caused by thermal degradation during pumping and transportation rarely occur.

| Appearance | Brownish liquid |

|---|---|

|

pH |

Approx. 7.5 (50 mass% aqueous solution of this product) |

| Viscosity | Approx. 450 mPa (25℃、BL viscometer) |

| Active ingredient | Approx. 43 mass% (evaporation residue after drying at 130°C for 90 min) |

| Solubility | Dissolves in water |

Pigment dispersant "CARRYBON L-400" applications and uses

Use as a dispersing agent for dispersing various inorganic pigments (e.g., calcium carbonate, clay, satin white, aluminum hydroxide, etc.) in water.

Examples of uses

Pigment dispersants

Cement dispersant

Lime slurry dispersant

Amount used

The amount used depends on the type and particle size of the pigment and the concentration of the dispersion solution, but the standard amount is 0.01-3.0 mass percent (active ingredient) of the pigment.

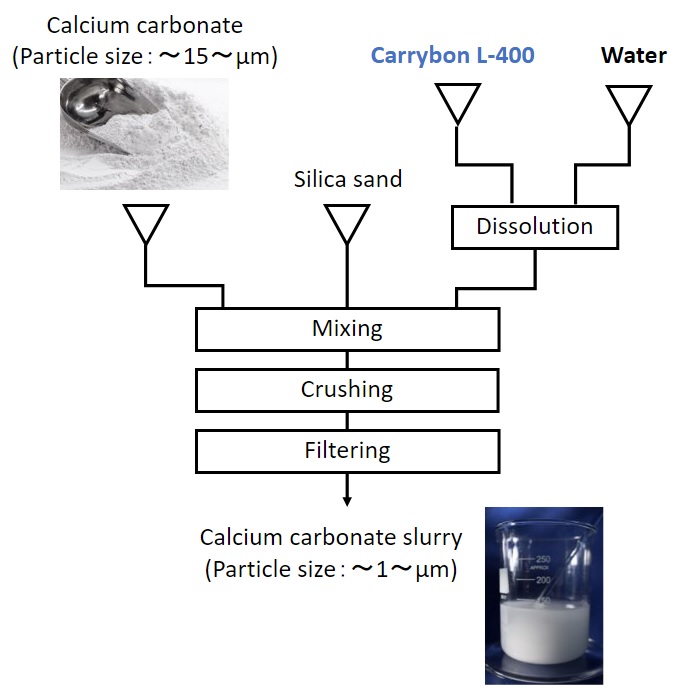

Example of pigment dispersion method (wet dispersion)

Fig. Example of pigment slurry preparation method by wet dispersion (Photo is an image only)

Dispersion of fine pigments

When dispersing fine pigments in water, pigments can be added to an aqueous solution containing a predetermined amount of CARRYBON L-400 under agitation and dispersed in a dispersing machine to prepare a pigment slurry.

Dispersion of pigments with coarse particle diameter

When dispersing coarse pigments in water while wet milling, a pigment slurry can be prepared by adding a predetermined amount of CARRYBON L-400, water, and silica sand, and dispersing in a dispersing machine. The figure below shows an example of how to prepare a pigment slurry by wet milling.

Sanyo Chemical's pigment dispersants

performance of "CARRYBON L-400"

Viscosity reduction effect on pigment slurry

1

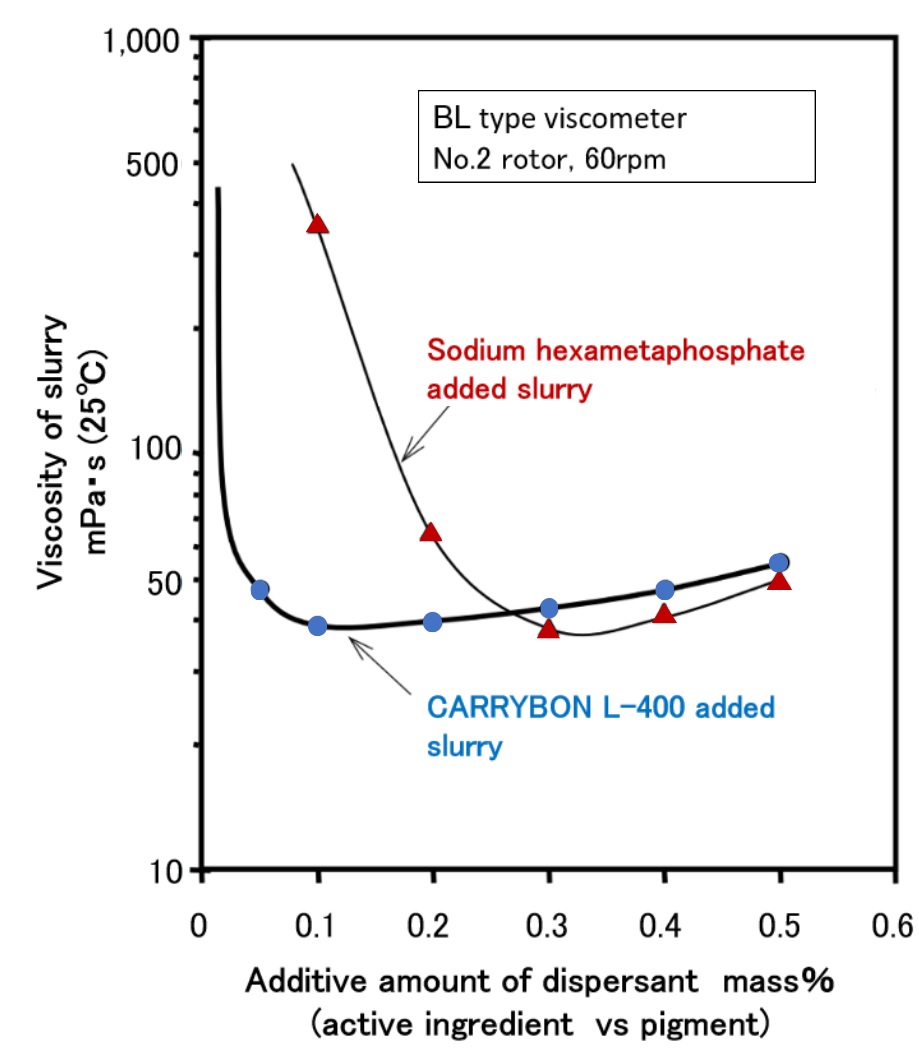

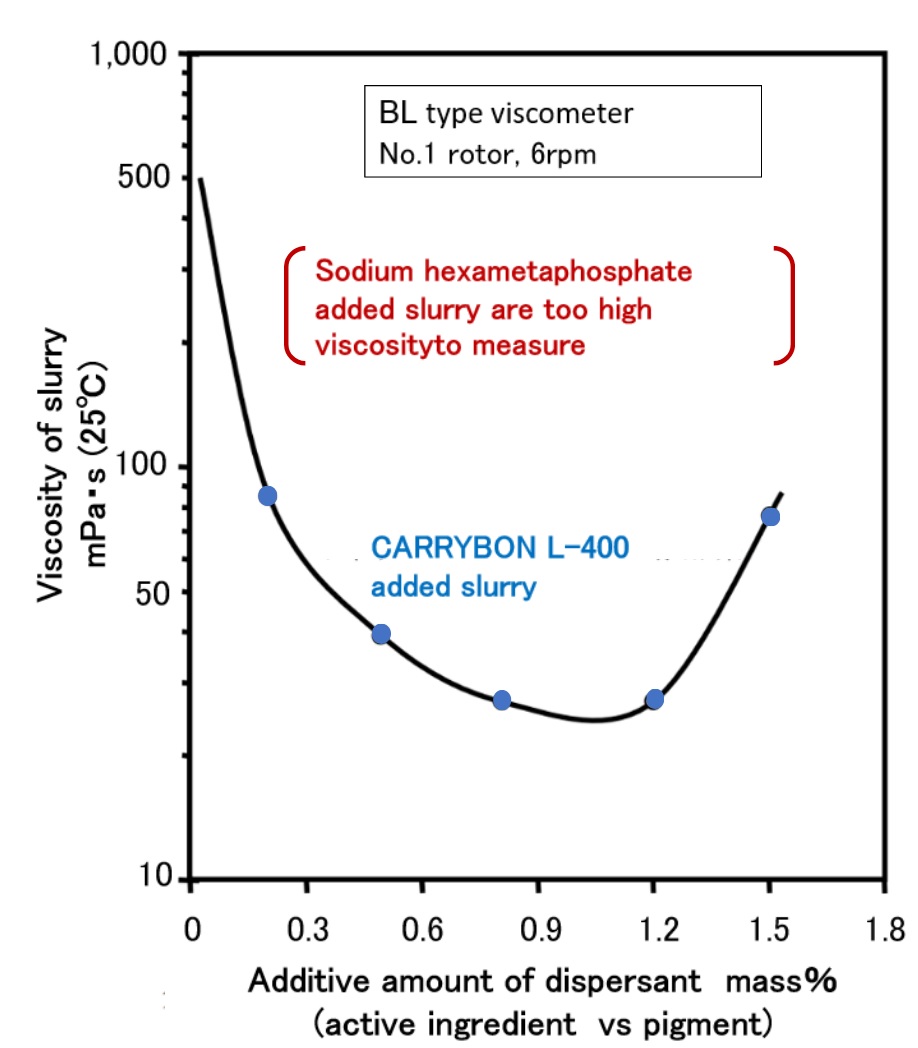

Viscosity reduction effect on slurries containing 70 mass% calcium carbonate

Relationship between the amount of dispersant added and slurry viscosity

(Slurry containing 70 mass% calcium carbonate)

2

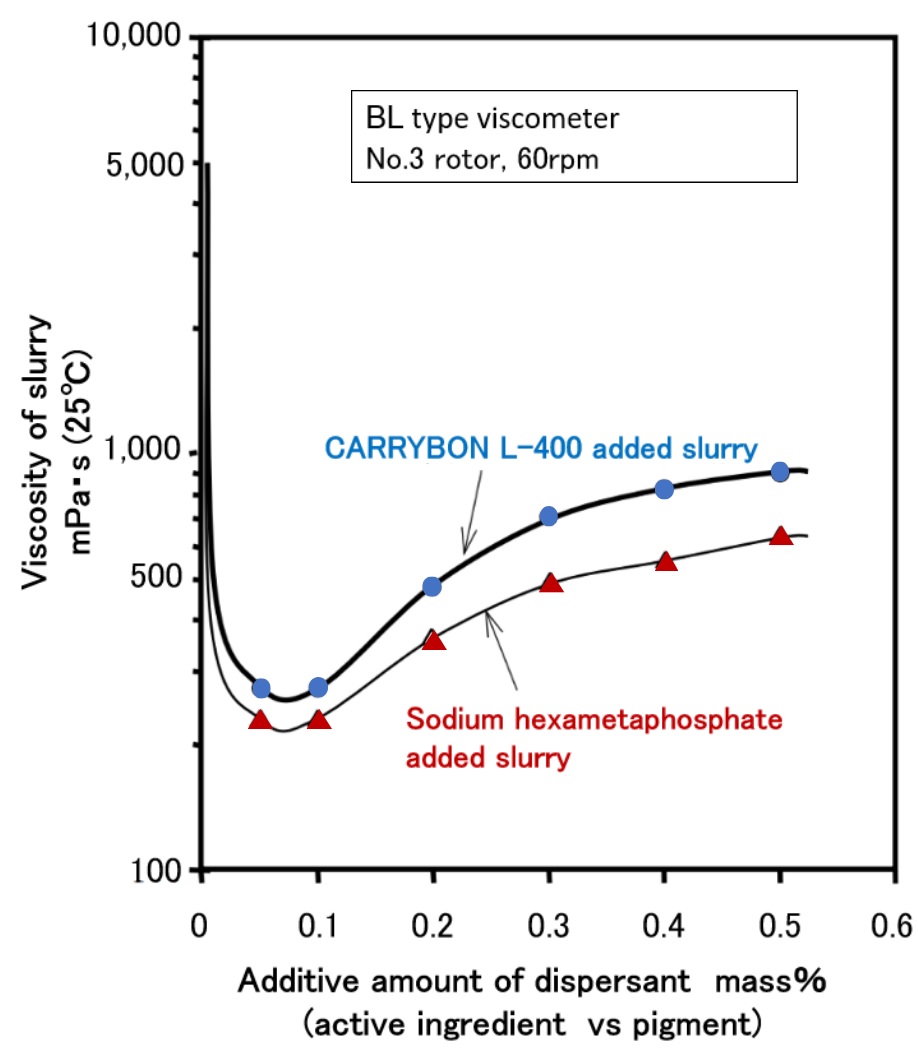

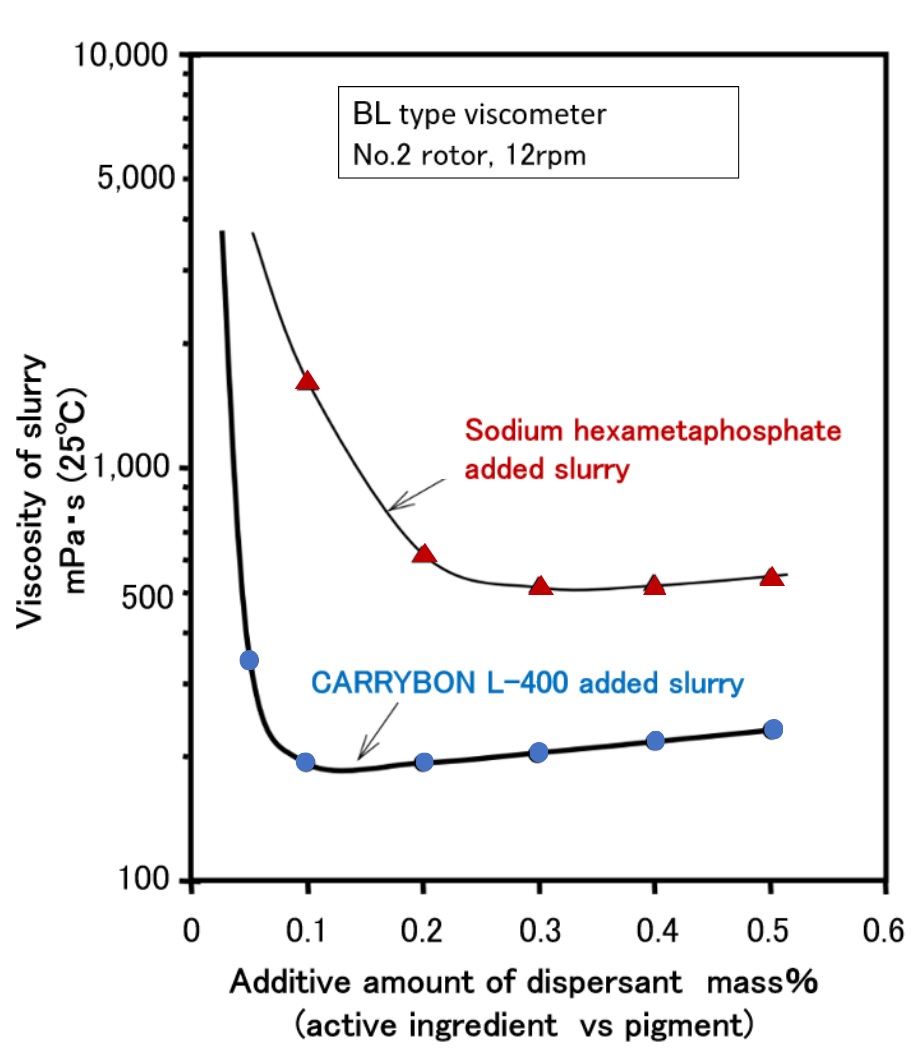

Viscosity reduction effect on slurries containing 70 mass% clay

Relationship between the amount of dispersant added and slurry viscosity

(Slurry containing 70 mass% clay)

3

Viscosity reduction effect on slurry containing 25 mass% Satin White

Fig. Relationship between dispersant addition amount and slurry viscosity

(Slurry containing 25 mass% Satin White)

4

Viscosity reduction effect on slurries containing 70mass% aluminum hydroxide

Relationship between the amount of dispersant added and slurry viscosity

(Slurry containing 70 mass% aluminum hydroxide)

Test Method

Sample:

A sample was prepared by mixing the prescribed amount of inorganic pigment, dispersant, and water as shown in the above figure in a dispersing machine.

Measuring method:

The viscosity of the sample was measured at 25°C. The rotor and rotational speed of the viscometer are shown in the figure.

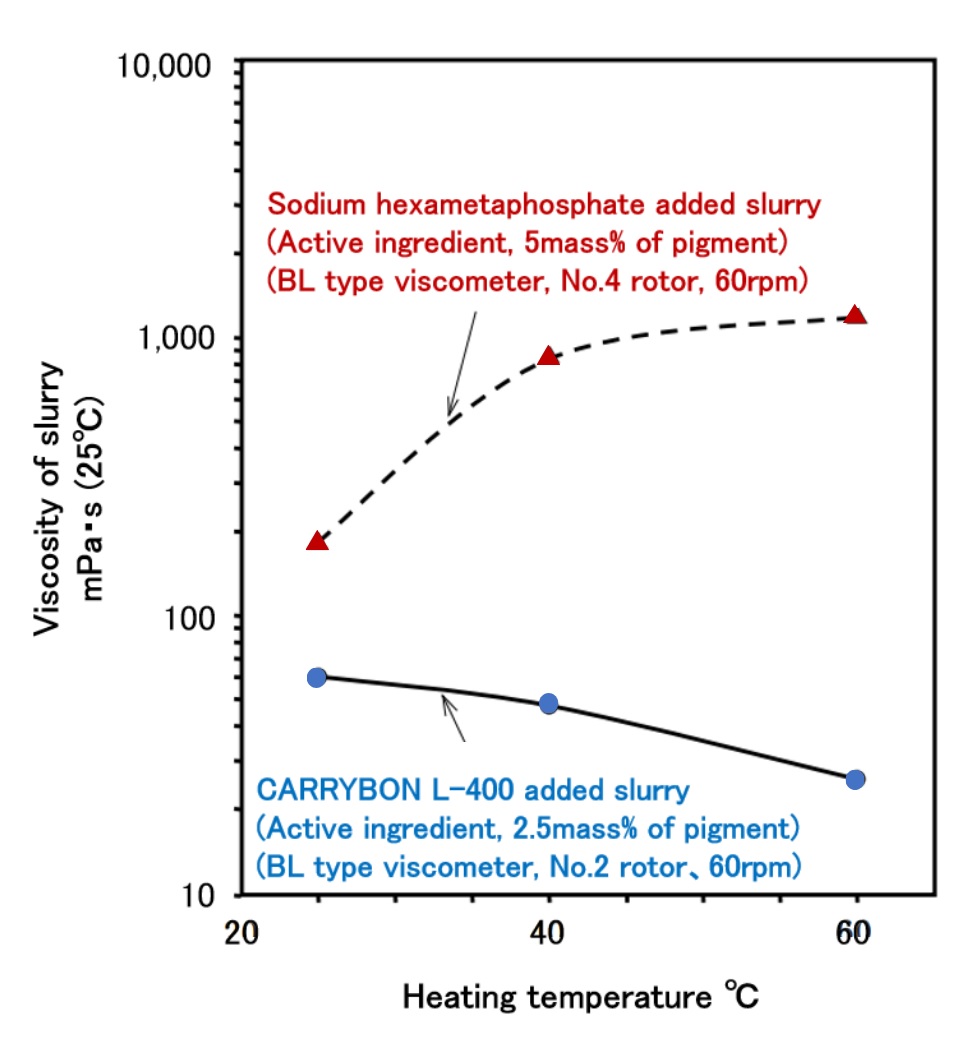

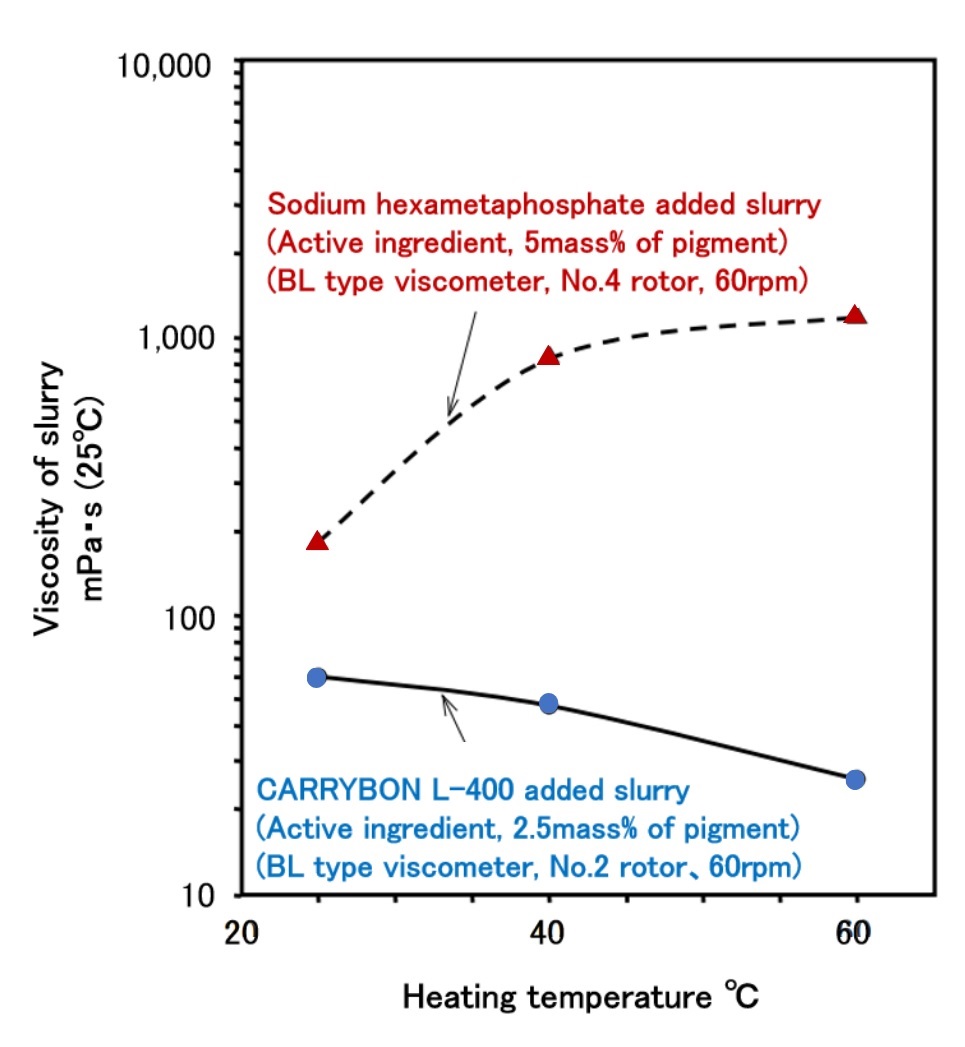

Viscosity stability of pigment slurry when heated

A slurry containing 20 mass% satin white :

Viscosity after heating

The temperature of the pigment slurry may rise when transporting by pump. Pigment slurries using inorganic phosphate dispersants, such as sodium hexametaphosphate, may increase in viscosity due to thermal degradation, which may affect pump transportation.

Pigment slurries using "CARRYBON L-400" as a dispersing agent have excellent viscosity stability when heated, so problems caused by thermal degradation during pumping and transportation rarely occur.

Test Method

Sample:

A sample was prepared by mixing the prescribed amount of inorganic pigment, dispersant, and water as shown in the above figure in a dispersing machine.

Measuring method:

The sample was allowed to stand at a predetermined temperature for 3 hours, and the viscosity was measured at 25°C. The rotor and rotational speed of the viscometer are shown in the figure. The rotor and rotational speed of the viscometer are shown in the figure.

Viscosity stability of pigment slurry over time

A slurry containing 20 mass% Satin White

Viscosity change over time

Pigment slurries using inorganic phosphate dispersants such as sodium hexametaphosphate can increase in viscosity over time, which can affect transportation and coating processes.

Pigment slurries using CARRYBON L-400 have excellent viscosity stability over time, so they rarely cause such problems.

Test Method

Sample:

Inorganic pigment, dispersant, and water as shown in the above figure were stirred in a dispersing machine to make a sample.

Measuring method:

The sample was kept at 25°C and the viscosity at 25°C was measured at intervals of a predetermined time. The rotor and rotational speed of the viscometer are shown in the figure.

Precautions for use

Before handling this product, be sure to read the "Safety Data Sheet" (SDS) for this product and its sub-materials (chemicals). Safety Data Sheets (SDS) for this product are available at our sales offices.

Related Information

Related products

-

Acrylic polymers

-

Link to Sanyo Chemical's corporate site

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist