Sizing Agent for Carbon Fibers"CHEMITYLEN"

Carbon fibers with less fluff and excellent processability are obtained, contributing to the production of high-strength and highly reliable (Carbon Fiber Reinforced Polymer)CFRP.

Sanyo Chemical's "CHEMITYLEN" Products Binder/Sizing Agent for Carbon Fibers

1

Modified carbon fibers by "CHEMITYLEN"

High quality carbon fibers with excellent handling and processability is obtained by using "CHEMITYLEN"

- It prevents fluffing by imparting properties, facilitates handling, and protects carbon fibers from damage in the processing.

- The resulting carbon fiber bundles are flexible, have excellent texture, and high processability (openability* and cuttability).

- Improves impregnation of matrix resin.

*Fiber opening property: A property that enables thin and uniform spreading of carbon fibers in the fiber opening process, in which carbon fiber bundles are unraveled to spread carbon fibers in order to facilitate impregnation of the matrix resin.

2

Modified carbon fibers reinforced plastic (CFRP) by "CHEMITYLEN"

- Fibers are easily arranged in a homogeneous manner while maintaining fiber length, resulting in CFRP with excellent fiber homogeneity. The adhesion between carbon fibers and matrix resin is also excellent, resulting in high strength.

- The undulations of the yarn can be reduced, and CFRP with excellent surface smoothness can be obtained.

- It also has excellent heat resistance.

3

Various lineups for different applications

- "CHEMITYLEN HP, EP" products with excellent impregnability to epoxy resins

- "CHEMITYLEN UA" products with excellent flexibility and cuttability.

- "CHEMITYLEN WS" products with good dispersibility in water and the ability to wash off the sizing agent component from carbon fibers

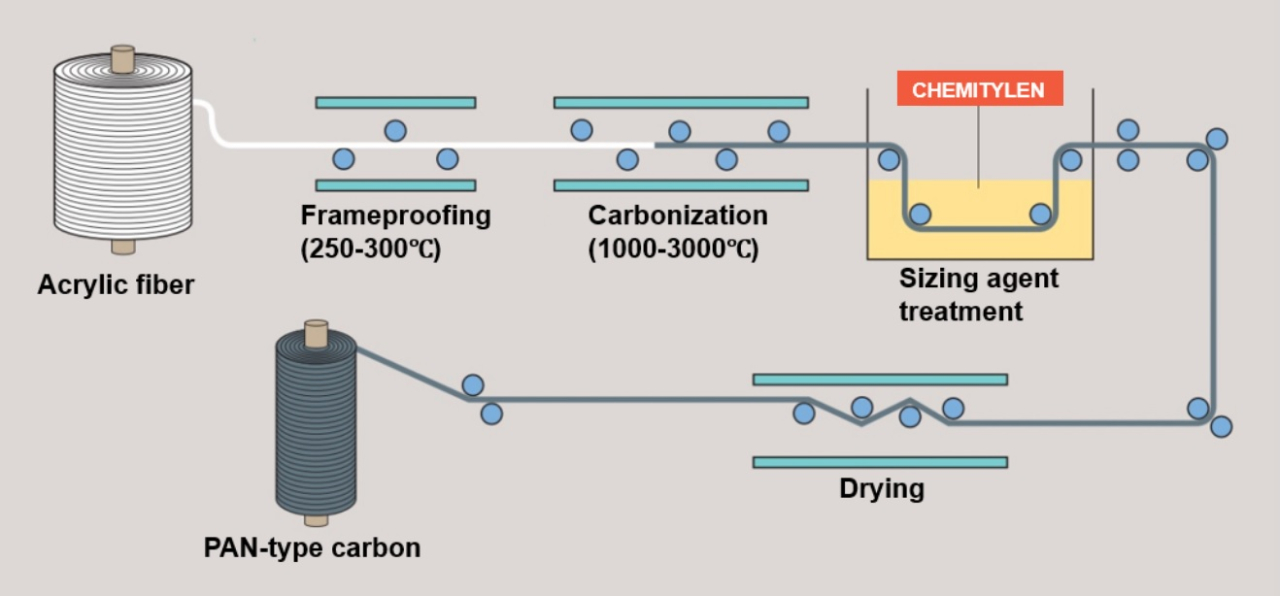

"CHEMITYLEN" products are sizing agents that bind carbon fibers together for easier handling.

"CHEMITYLEN" products, sizing agents, are used in a variety of carbon fiber composite products.

Carbon fiber composite materials can achieve both high strength and light weight, contributing to energy saving and reduction of environmental impact in various fields.

Examples of Uses

1

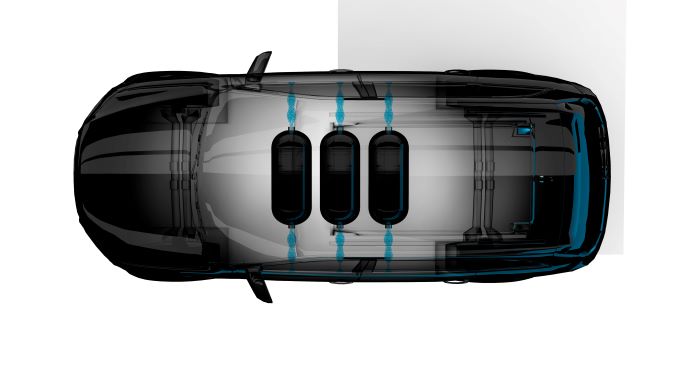

Pressure vessel

Molded by filament winding using sized carbon fibers.

2

Wind turbine components

Molded by pull-torsion using sized carbon fibers.

3

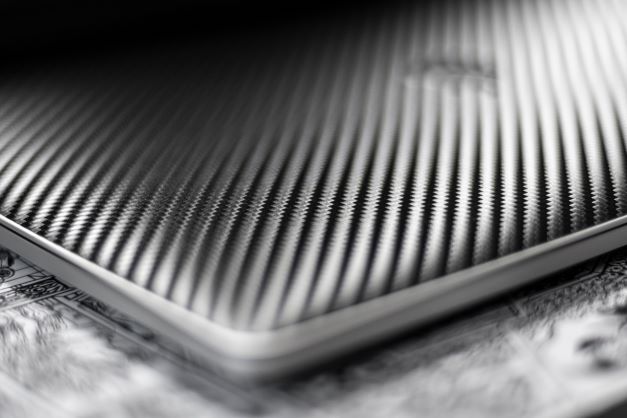

Top panel for X-ray diagnostic equipment

Sized carbon fibers are used as prepreg and press molded.

4

Aircraft Components

Sized carbon fibers are used as prepreg and autoclave molded.

5

Automotive Components

Sized carbon fibers are woven and molded by RTM process (cured after pre-molding)

6

Laptop chassis

Sized carbon fibers are pelletized as chop fiber and then injection molded.

Features of each grade in the "CHEMITYLEN" products

| Products | Features | Effects |

|---|---|---|

| CHEMITYLEN HP・EP (Polyester/Epoxy type) | Excellent impregnation of epoxy resin. | Wets well with epoxy resin and produces high-strength FRP. |

| Excellent fiber-opening properties. | Produces a wide, thin tow. | |

| Less fluffing. | Fiber length can be maintained and high-strength FRP can be made. | |

| CHEMITYLEN UA (Polyurethane type) | Excellent flexibility and cuttability. | Produces flexible, easy-to-handle, easy-to-chop tow. |

| Excellent mixing stability with EP and HP series. | The physical properties can be adjusted to your liking by mixing. | |

| CHEMITYLEN WS (Polyether type) | Good dispersibility in water. | When you do not want to leave the sizing agent component on the surface of carbon fiber, it can be washed off with water. |

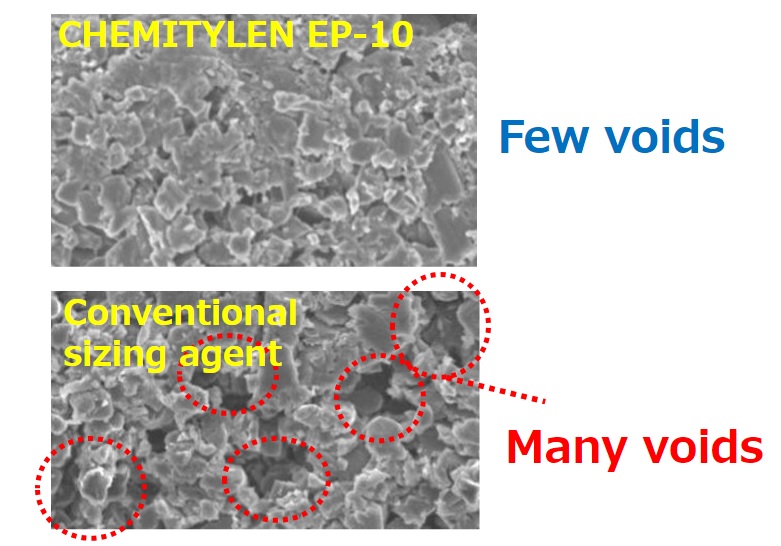

"CHEMITYLEN EP・HP" products

Fig. Carbon fiber composite material after epoxy resin impregnation

SEM photograph of cross section (800x)

<Features >

- Excellent epoxy resin impregnation

- Excellent bundling and opening properties

- Less fluffing

<General composition>

- Special polyester

- Bisphenol A epoxy resin

- Nonionic activator

- Water

Comparison of performance between conventional sizing agents and "CHEMITYLEN EP and HP" products

| Item | Conventional sizing agents (Main component: epoxy resin) | CHEMITYLEN EP-10 | CHEMITYLEN HP-10 | |

|---|---|---|---|---|

| Adhesion amount wt% | 1.5 | 1.5 | 1.5 | |

| Carbon fiber tow basic performance | Fluff amount mg | 2.9 | 0.7 | 0.5 |

| Convergence cm | 13.4 | 18.6 | 17.1 | |

| Openness mm | 6.5 | 6.7 | 7.4 | |

| Epoxy resins aggregation s | 18.5 | 6.9 | 5.7 | |

| Emulsion stability | Stability over time 25℃×6months | Fair | Good | Good |

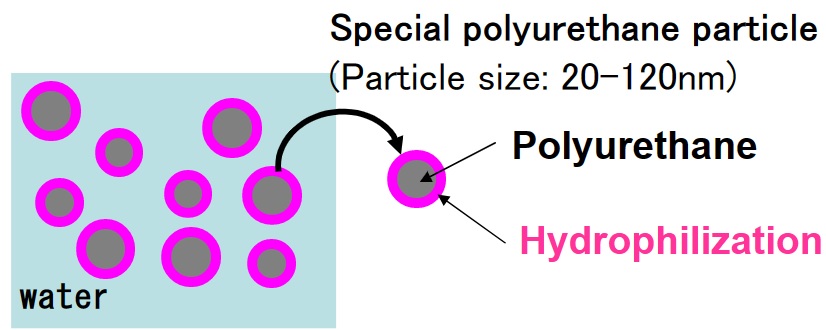

"CHEMITYLEN UA" products

Fig. CHEMITYLEN UA products

<Features>

Moderate flexibility

Excellent cuttability

Excellent cuttability due to excellent mixing stability with CHEMITYLEN EP and HP products.

Bundling and opening properties can be adjusted by mixing with EP and HP products.

<General composition >

Special polyurethane

Water

Comparison of performance between conventional sizing agent and "CHEMITYLEN UA-40"

| Item | Conventional sizing agent (Main component: epoxy resin) | CHEMITYLEN UA-40 |

|---|---|---|

| Adhesion amount wt% | 1.5 | 1.0 |

| Convergence cm | 13.4 | 18.3 |

| Cuttability |  |  |

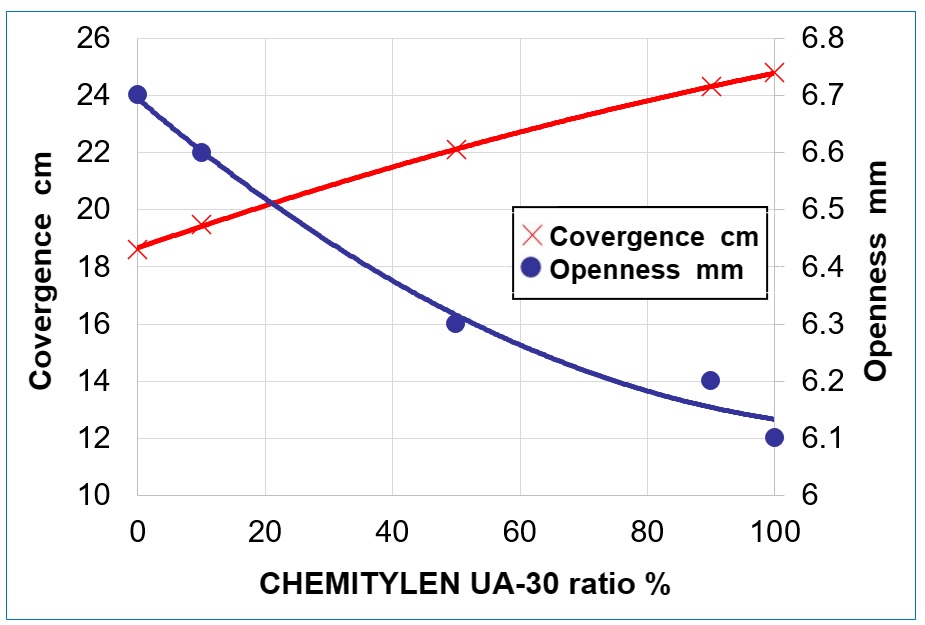

Mixing data of "CHEMITYLEN EP" and "CHEMITYLEN UA" products

Example of performance adjustment by mixing Chemtylen EP-10/UA-30

Excellent mixing stability with CHEMITYLEN EP and HP products

The mixing stability of "CHEMITYLEN EP and HP" products is excellent, so bundling and opening properties can be adjusted by mixing.

"CHEMITYLEN WS" products

< Features >

A water-soluble type carbon fiber sizing agent with excellent solubility in water.

| Item | CHEMITYLEN WS-10 | CHEMITYLEN WS-20 |

|---|---|---|

| Main composition | Polyether aqueous solution | Modified polyether aqueous solution |

| Concentration | 50 | 30 |

| Viscosity (25°C, mPa-s) | 3000 | 25000 |

Comparison of performance between conventional sizing agent and "CHEMITYLEN" WS products

| Item | Conventional sizing agent (Main component: epoxy resin) | CHEMITYLEN WS-10 | CHEMITYLEN WS-20 |

|---|---|---|---|

| Adhesion amount wt% | 1.5 | 1.5 | 1.5 |

| Convergence cm | 13.4 | 13.1 | 23.8 |

| Openness mm | 6.5 | 6.6 | 6.4 |

Main lineup of "CHEMITYLEN" products

"CHEMITYLEN" products performance list

| Product | Carbon fiber tow performance | Heat resitance | |||

|---|---|---|---|---|---|

| convergence | tack | densitometry | fluff | Tg ℃ * | |

| CHEMITYLEN HP-10 | normal | midldle | excellent | excellent | 300 |

| CHEMITYLEN EP-10 | good | midldle | excellent | good | 310 |

| CHEMITYLEN UA-10 | excellent | weak | normal | excellent | 270 |

| CHEMITYLEN UA-20 | excellent | weak | good | excellent | 250 |

| CHEMITYLEN UA-30 | good | weak | good | good | 270 |

| CHEMITYLEN UA-40 | good | weak | excellent | good | 230 |

| CHEMITYLEN WS-10 | poor | strong | good | N/A | 220 |

| CHEMITYLEN WS-20 | good | midldle | good | N/A | 310 |

List of properties of "CHEMITYLEN" Products

| Product | Liquid type | Concentration % * | Resin type | Ionic species |

|---|---|---|---|---|

| CHEMITYLEN HP-10 | emulsion | 40 | modified polyester | nonion |

| CHEMITYLEN EP-10 | emulsion | 40 | modified polyester | nonion |

| CHEMITYLEN UA-10 | emulsion | 39 | modified polyurethane | anion |

| CHEMITYLEN UA-20 | emulsion | 38 | modified polyurethane | anion |

| CHEMITYLEN UA-30 | emulsion | 40 | modified polyurethane | anion |

| CHEMITYLEN UA-40 | emulsion | 35 | modified polyurethane | anion |

| CHEMITYLEN WS-10 | aqueous solution | 50 | polyether | ー |

| CHEMITYLEN WS-20 | aqueous solution | 50 | modified polyether | ー |

Related Information

Related Products

- Link to Sanyo Chemical's corporate site

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist