Polyoxyalkylene lauryl ether-type nonionic surfactant"EMULMIN FL, HL" products

Non-ionic surfactant (polyoxyalkylene lauryl ether) made from natural lauryl alcohol.

Here is what's great about "EMULMIN FL, HL" products

1

Surfactants made from natural products

"EMULMIN FL and HL" products are non-ionic surfactants (polyoxyalkylene lauryl ether) made from natural lauryl alcohol.

2

Good low-temperature flowability

Compared to other nonionic surfactants that exhibit nearly the same cloud point, it has a lower flow point, better low-temperature flowability, and faster dissolution rate in cold water, making it easier to transfer and blend.

3

Excellent cleaning and dispersing power

"EMULMIN FL and HL" products have excellent cleaning and dispersing power, and are widely used as raw materials in a variety of detergents, as well as emulsifiers, dispersants, wetting agents, and other applications in the textile industry, paper and pulp industry, synthetic resin industry, metal industry, and other industries.

| EMULMIN FL-80 | EMULMIN FL-100 | EMULMIN HL-100 | |

|---|---|---|---|

| Appearance (20±5℃) | Colorless to pale yellow liquid | Colorless to pale yellow liquid | Colorless to pale yellow liquid |

| Cloud point *1 ℃ |

52 | 61 | 61 |

| pH *2 | 6.5 | 7.0 | 7.0 |

| Viscosity mPa・s (25℃) |

53 | 64 | 75 |

| Flow point *3 ℃ |

-18 | -11 | -17 |

Examples of Applications and Formulations

"EMULMIN FL and HL" products have excellent detergency and emulsifying/dispersing power, and can be used in kitchen detergents, clothing detergents, household detergents, range cleaners, floor wax strippers, and bottle washer detergents. Examples of formulations for these applications are shown below.

Formulation example for kitchen detergent

| mass% | |

|---|---|

| EMULMIN FL-80 | 5 |

| Sodium alkyl ether sulfate | 12 |

| Coconut oil fatty acid diethanolamide | 3 |

| Ethanol | 2 |

| water | as needed |

| Total amount | 100 |

Formulation example for liquid laundry detergent

| mass% | |

|---|---|

| EMULMIN FL-80 | 32 |

| Alkyl ether sulfate triethanolamine salt | 22 |

| Triethanolamine hydrochloride | 8 |

| Flavorings, colorings, etc. | as needed |

| water | as needed |

| Total amount | 100 |

Formulation example for powdered laundry detergent

| mass% | |

|---|---|

| EMULMIN FL-80 | 7 |

|

Sodium salt of linear alkylbenzene sulfonate |

18 |

| Zeolite | 13 |

| Sodium metasilicate | 11 |

| Sodium carbonate (Na2CO3) | 13 |

| Fatty acid soap (powder) | 2 |

| CMC sodium salt | 1 |

| Sodium sulfate (sulphate) | 33 |

| Fluorescent dyes, fragrances, colorants, moisture | as needed |

| Total amount | 100 |

Formulation example for Household Detergent

| mass% | |

|---|---|

| EMULMIN FL-100 | 3 |

| Sodium alkyl ether sulfate | 1 |

| Butylcarbitol | 6 |

| Flavorings, colorings, etc. | as needed |

| water | as needed |

| Total amount | 100 |

Formulation example of Bathtub Detergent

| mass% | |

|---|---|

| EMULMIN FL-100 | 10 |

| NEWPOL B-12 *1 | 8 |

| Citric acid | 2 |

| Ethylenediaminetetraacetic acid (EDTA) | 1 |

| Flavorings, colorings, etc. | as needed |

| water | as needed |

| Total amount | 100 |

*1: Our product, glycol ether type solvent

Performance data

Comparative data between EMULMIN FL-80, FL-100, and HL-100 and our conventional products regarding (1) surface activity performance, (2) flow point, and (3) performance as a kitchen detergent are shown below.

(1) Surface Active Performance

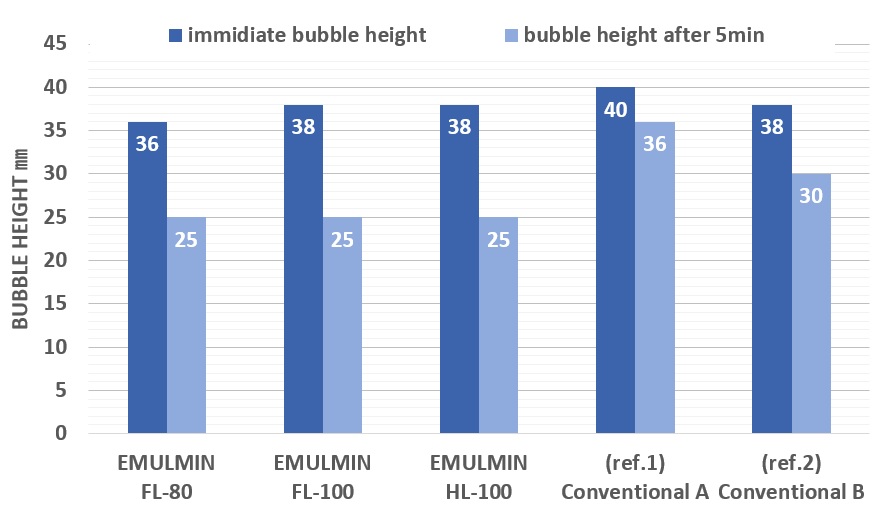

As shown in the table and figure below, the aqueous solutions of EMULMIN FL and HL products exhibit almost the same surface tension, permeability, and foaming power as the aqueous solutions of our conventional products, which have superior permeability and a similar cloud point.

| Product | Test concentration Mass percent |

Surface tension *1 mN/m |

Penetration *2 s |

Foaming power *3 Figures in () are after 5 min. mm |

|---|---|---|---|---|

| EMULMIN FL-80 | 0.01 | 28.9 | 12.1 | 36 (25) |

| 0.1 | 28.7 | 0.5 | 113 (32) | |

| EMULMIN FL-100 | 0.01 | 29.7 | 12.5 | 38 (25) |

| 0.1 | 29.6 | 0.6 | 115 (33) | |

| EMULMIN HL-100 | 0.01 | 29.7 | 12.5 | 38 (25) |

| 0.1 | 29.6 | 0.6 | 115 (33) | |

| (Comparison Example 1) Conventional product A *4 |

0.01 | 29.0 | 13.0 | 40 (36) |

| 0.1 | 28.9 | 0.7 | 114 (49) | |

| (Comparison Example 2) Conventional product B *5 |

0.01 | 29.2 | 12.5 | 38 (30) |

| 0.1 | 29.0 | 0.6 | 114 (47) |

*1: Wilhelmy method, measurement temperature 30°C

*2: Cotton canvas sedimentation method at 30°C

*3: Ross-Miles method, temperature 30°C, bubble height after 5 minutes

*4: Synthetic higher alcohol nonionic surfactant manufactured by our company

[Cloud point 81°C (2 mass% water dilution)]

*5: Synthetic higher alcohol non-ionic surfactant manufactured by our company

[Cloud point 56°C (2 mass% aqueous dilution)]

Comparison of foaming power of Emulmine FL and HL aqueous solutions (Ross-Miles method, 30°C, surfactant concentration 0.01 mass%)

(2) Flow point

As shown in the table on the right, the EMULMIN FL and HL products exhibit a lower flow point than our conventional products, which have similar cloud points.

| Flow point *1 ℃ |

|

|---|---|

| EMULMIN FL-80 | -17.5 |

| EMULMIN FL-100 | -12.5 |

| EMULMIN HL-100 | -15.0 |

| (Comparison Example 1) Conventional product A *2 | 20.0 |

| (Comparison Example 2) Conventional product B *3 | 5.0 |

*1: According to JIS K 2269

*2: Synthetic higher alcohol nonionic surfactant [Cloud point 81°C (2 mass% aqueous dilution)] manufactured by our company

*3: Synthetic higher alcohol nonionic surfactant [Cloud point 56°C (2 mass% aqueous dilution)] manufactured by our company

(3) Performance as a kitchen detergent

The table below shows the results of evaluation of detergency, viscosity, and low-temperature stability of model formulations of liquid kitchen detergents using the EMULMIN FL and HL products.

The "EMULMIN FL, HL" products shows good performance as a raw material for kitchen detergents.

| Cleaning power % |

Viscosity of sample mPa-s (30°C) |

Low temperature stability | |

|---|---|---|---|

| EMULMIN FL-80 | 99.0 | 18 | good |

| EMULMIN FL-100 | 99.0 | 21 | good |

| EMULMIN HL-100 | 99.0 | 21 | good |

| (Comparison Example 1) Conventional product A *2 | 98.5 | 53 | poor |

| (Comparison Example 2) Conventional product B *3 | 99.0 | 27 | good |

test procedure

Sample

A model formulation of liquid kitchen detergent with the following composition was used as the measurement sample.

mass%

Nonionic surfactant : 6 (active ingredient)

SANDET END *1 : 11 (active ingredient)

PROFAN 128 EXTRA *2 : 0.4

water : Remaining amount

--------------------------------------------------------------

Total :100mass%

*1: Our product, sodium salt of alkyl ether sulfate

*2: Coconut oil fatty acid diethanolamide

Method of measuring cleaning power

The cleaning power was measured according to the Lee-Nut method (JIS K 3370). However, six glass slides were used as a set of stain support, and a chloroform solution of artificial stain of the following composition was applied to the stain component. A 0.15 mass% aqueous dilution of the sample concentration (active ingredient) was used as the cleaning solution, and the supports coated with the artificial stain were cleaned using a Lehnhardt modified method tester to obtain the cleaning power from the following formula.

Artificial stain

Artificial stain was made by dissolving 20 g of a mixture of beef tallow and soybean oil at a volume ratio of 1:1, 0.25 g of monoolein, and 0.1 g of oil red in 60 ml of chloroform.

Washing power

Cleaning power = (amount of stain before cleaning g - amount of stain after cleaning g) × 100 / amount of stain before cleaning g

Viscosity Measurement Method

The viscosity of the sample was measured at 30°C using a B-type viscometer.

Low Temperature Stability Measurement Method

After the sample was left at -5°C for 24 hours, its appearance was visually observed and judged according to the following criteria.

good: Clear liquid

poor: Cloudy

In addition to surfactants, detergents may contain appropriate foam stabilizers, solubilizers, and builders. Please check the performance, safety, and stability of these formulations in advance.

EMULMIN FL, HL" series are non-ionic surfactants. Therefore, if they are used together with sodium hypochlorite in bleach applications, sodium hypochlorite will decompose and the oxidizing effect of sodium hypochlorite will oxidize "EMULMIN FL, HL" series, causing performance degradation. Therefore, do not use with sodium hypochlorite bleaches.

Please be sure to read the "Safety Data Sheet" (SDS) for each product and sub-material (chemical) before handling the products listed on this website. The SDS can be obtained from here. https://www.sanyo-chemical.co.jp/products/en/sds/

Related information

Related products

-

Link to Sanyo Chemical's corporate site

EMULMIN FL-100, EMULMIN FL-80, EMULMIN HL-100

EMULMIN 140, EMULMIN 180, EMULMIN 200, EMULMIN 240

EMULMIN 40, EMULMIN 50, EMULMIN 70

EMULMIN 862

EMULMIN AF-101

EMULMIN CC-150, EMULMIN CC-200, EMULMIN CCE-130, EMULMIN CS-100W

EMULMIN L-90-S, EMULMIN LS-80, EMULMIN LS-90

EMULMIN NL-100, EMULMIN NL-110, EMULMIN NL-70, EMULMIN NL-80, EMULMIN NL-90

Products search

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist