Biodegradable lubricant base"EXCEBIOL" (product in development)

Water soluble, biodegradable and lubricating

Polyalkylene glycol-based lubricant base

What's great about Sanyo Chemical's Biodegradable Lubricant Base "EXCEBIOL"

1

Good water solubility and biodegradability

The "EXCEBIOL" products have excellent water solubility, so it mixes easily with water and does not separate over time, maintaining a uniform liquid state.

The "EXCEBIOL" products are biodegradable, making it an environmentally friendly lubricant base in the event of a leak.

2

Excellent lubrication function

It has excellent lubricating functions and is useful as a lubricant base in various applications.

3

Extensive lineup covers a wide range of viscosities

The "EXCEBIOL" products cover a wide range of viscosities with a rich lineup, allowing a grade selection that best suits various applications.

"EXCEBIOL" products are a polyalkylene glycol-based lubricant base that is friendly to people and the environment.

Intended use

"EXCEBIOL" is biodegradable, and as a lubricant base can contribute to reduced environmental impact in various fields in the event of a leak, etc.

1

Marine energy

Can be used as a lubricant base in marine energy-related fields.

2

Ship related

Can be used as a base for lubricating screws and other power sources in the marine industry.

3

Agricultural Machinery/Construction Machinery

Can be used as a lubricant base in the field of agricultural and construction machinery.

4

Molding and processing

Can be used as a mold release agent in the molding and processing field.

Main properties of "EXCEBIOL"

Main properties of the "EXCEBIOL" products and comparison with other base oils

| Water solubility | Biodegradability ≧60%:good | Lubricity (coefficient of friction [SRV method*] μ(100N) | Viscosity at 40℃ mm2/s | Viscosity at 100℃ mm2/s | Flow point ℃ | |

|---|---|---|---|---|---|---|

| EXCEBIOL MR-260 | soluble | good | 0.116 | 49 | 11 | -49 |

| EXCEBIOL MR-660 | soluble | good | 0.116 | 141 | 26 | -45 |

| EXCEBIOL TE-600 | soluble | good | 0.153 | 91 | 12 | -61 |

| EXCEBIOL DE-300 | soluble | good | 0.156 | 34 | 6 | -13 |

| EXCEBIOL DE-1000 | soluble | good | 0.147 | - | 17 | 37 |

| Ester base oil | Insoluble (separation) | good | 0.137 | 69 | 8 | -40 |

| Mineral oil base oil | Insoluble (separation) | poor | 0.180 | 37 | 7 | -13 |

| PAO base oil | Insoluble (separation) | poor | 0.230 | 30 | 6 | -61 |

*Test conditions for lubricity [SRV method]: Lubricity (coefficient of friction) evaluation using an oscillating friction and wear test (SRV tester)

Test specimen: Steel ball (SUJ-2, Φ 10 mm), steel disk (SUJ-2)

Test conditions: Load 100 N (50 → 500 N), frequency 50 Hz, vibration width 1.0 mm, temperature 40°C

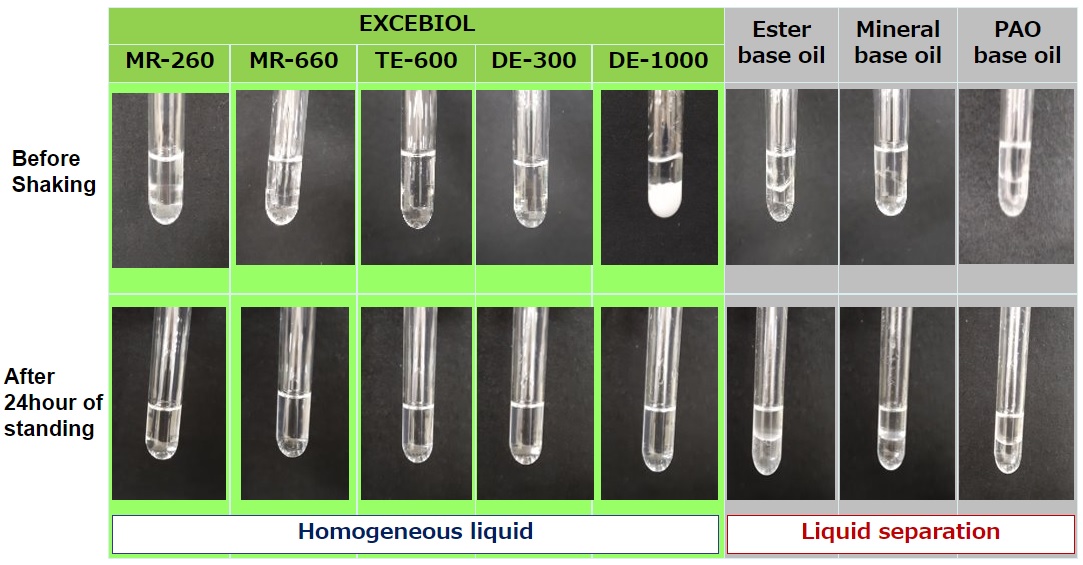

Water solubility of "EXCEBIOL"

Water solubility evaluation of "EXCEBIOL"

"EXEBIOL" can be easily mixed with water and maintained in a homogeneous state by mixing with water and shaking.

<Test Method>

"EXCEBIOL" water solubility evaluation test

A two-layer sample was prepared by weighing 2mL of each part of "EXCEBIOL" in a test tube and gently adding 2 ml of water.

(For "EXCEBIOL DE-1000," 3mL of water was added to 1g of sample.)

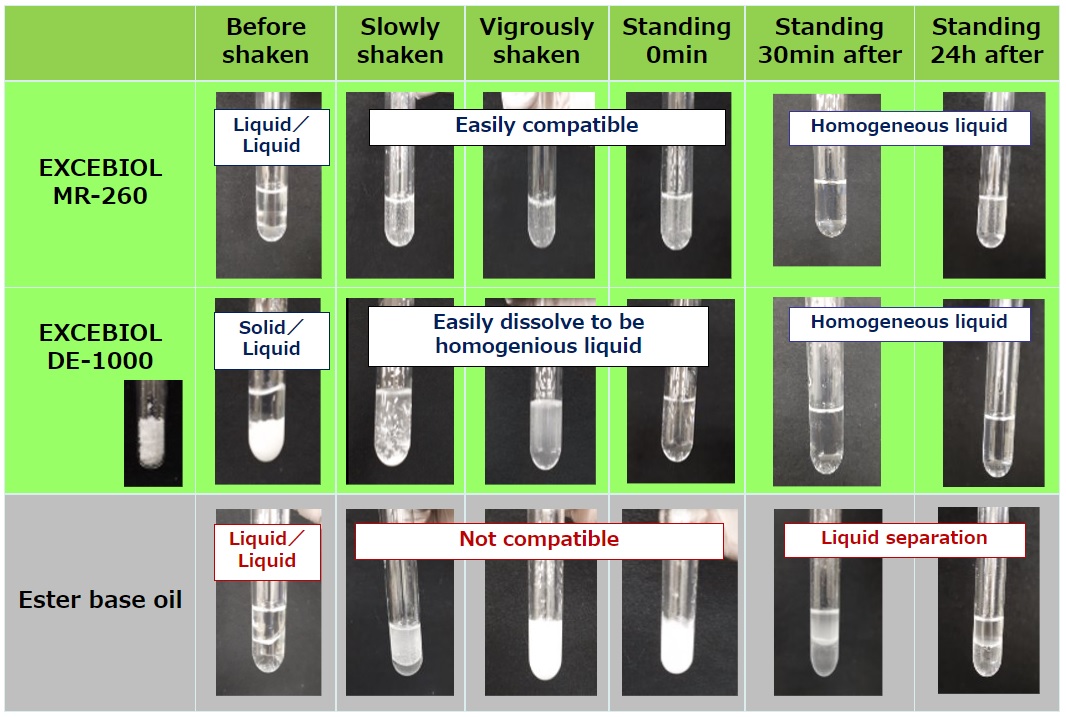

The sample was first shaken gently and then gradually and vigorously to check its compatibility with water.

The compatibility of the samples with water was confirmed by shaking the samples gently and then gradually more vigorously. [The photographs in the table above show the appearance before shaking and after 24 hours of standing.]

Comparison test

The ester/mineral oil/PAO base oil was operated in the same way except that each oil was added to water, and it was confirmed that the oil separated from the water over time.

Change in appearance during water solubilization of "EXCEBIOL"

Related Information

Related products

- Links to Sanyo Chemical's corporate site

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist.