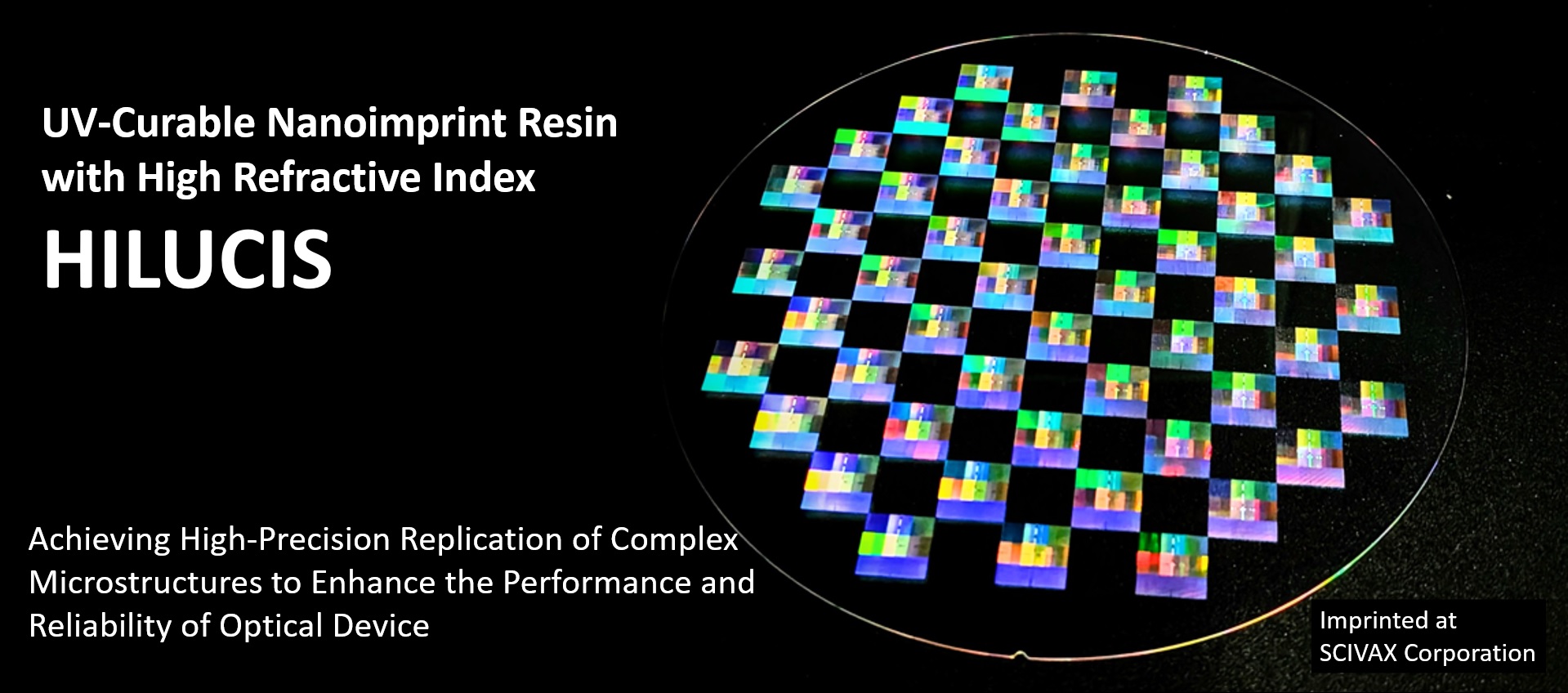

UV-Curable Nanoimprint Resin with High Refractive Index"HILUCIS"

Revolutionizing Next-Generation AR/VR Optical Devices

UV-Curable Nanoimprint Resin with Superior Light Resistance and High Refractive Index

What is Great about Sanyo Chemical's UV-curable Nanoimprint Resin with High Refractive Index “HILUCIS"

1

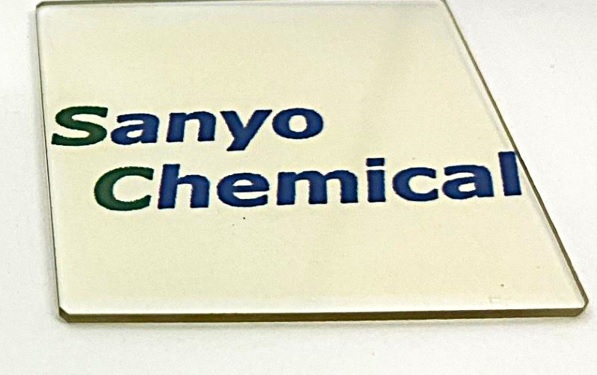

Superior Optical Performance (Transparency and Refractive Index)

・High refractive index (nd = 1.9)

・High transparency

light transmittance on glass: ≥90%

low haze:≤0.1%

2

High Light Resistance

—Contributes to Enhanced Reliability of Optical Devices

• Maintains transparency with minimal yellowing after exposure to UV radiation.

• Ensures vivid, long-lasting optical performance.

| HILUCIS | Conventional high refractive index resin (Reference model) |

|---|---|

|

|

3

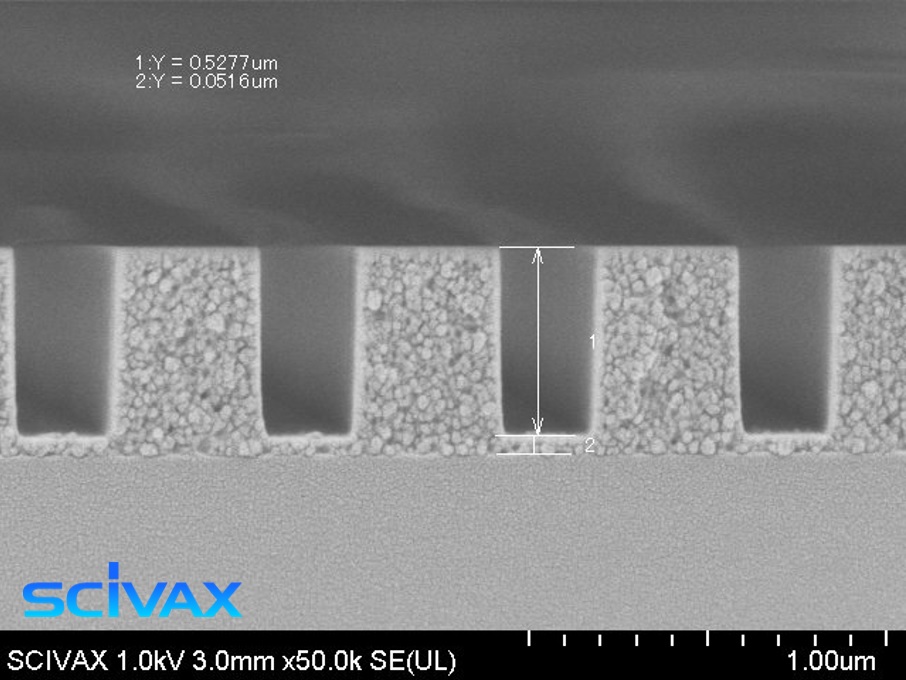

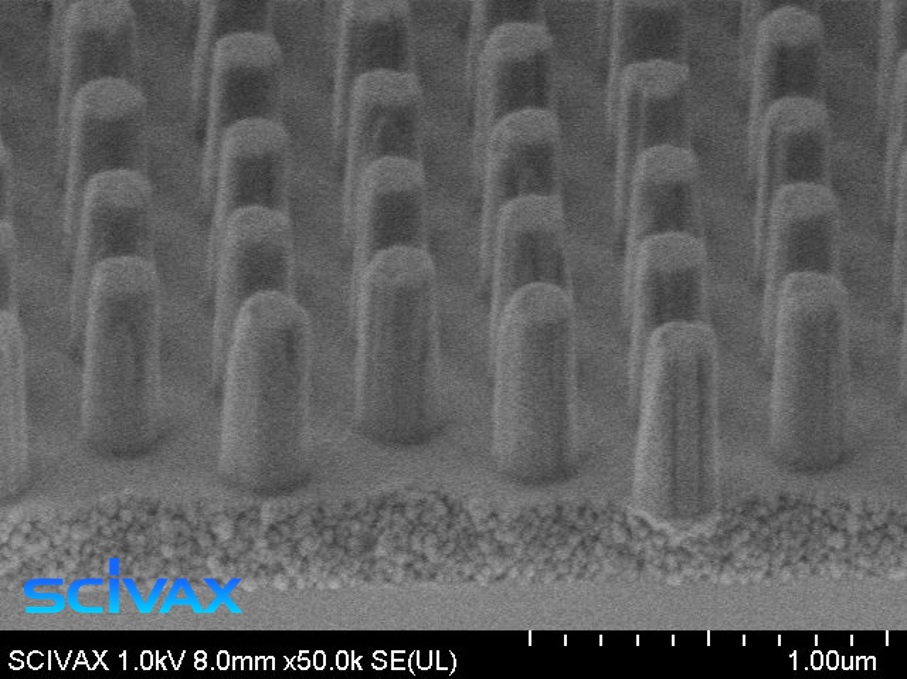

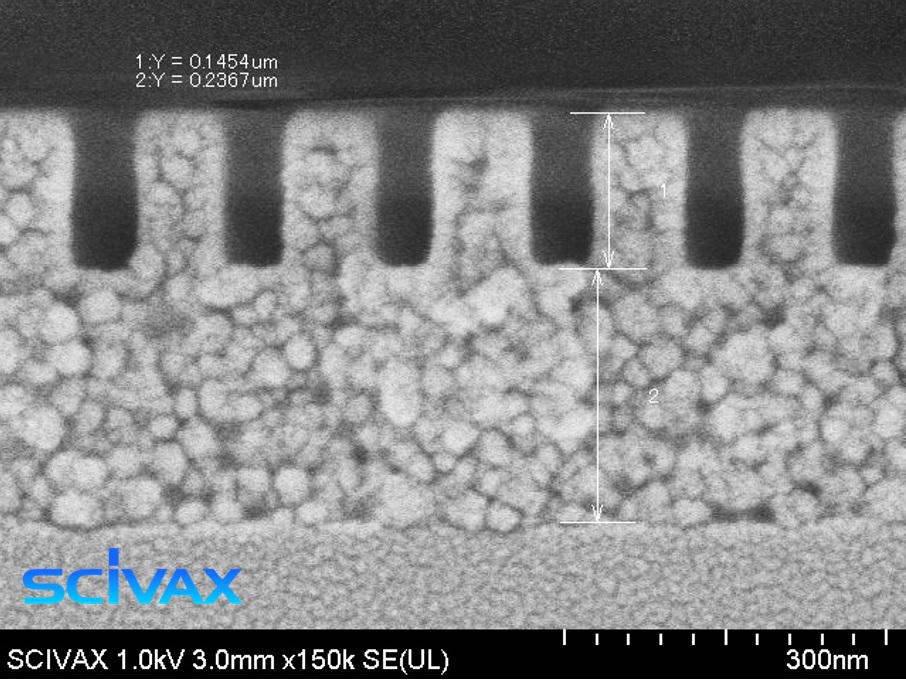

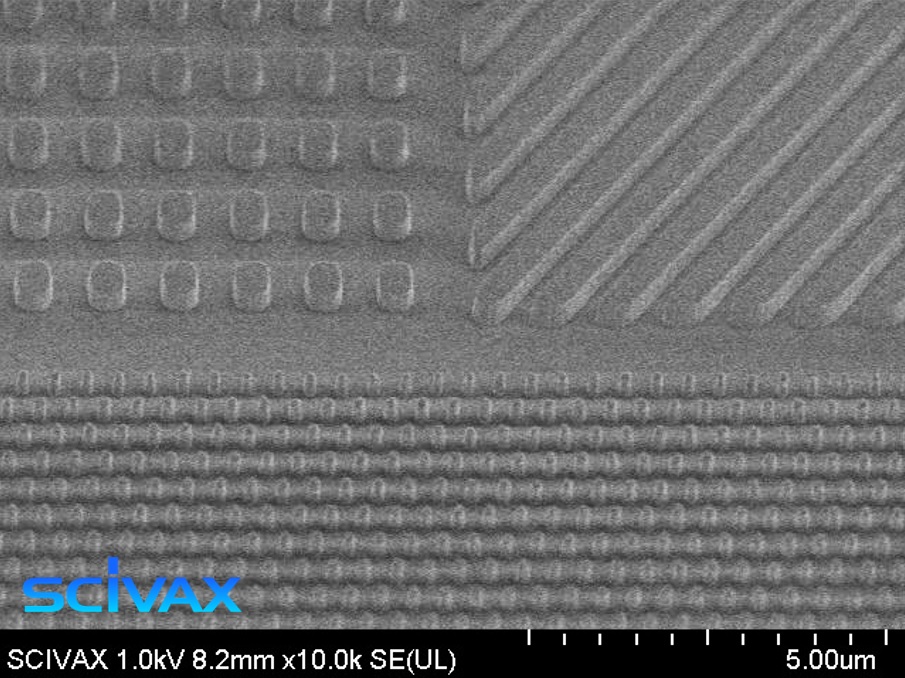

Exceptional Nanoimprint Compatibility

—Contributes to Enhanced Performance and Yield of Optical Devices

• Accurately replicates intricate patterns, even with significant density variations where areas of high and low density coexist on a single substrate.

• Produces thin, uniform residual films, enhancing optical system design flexibility.

Accurately replicates intricate patterns. Produces thin, uniform residual films (≦50nm)

Imprinted with RubiQ

Imprinted with RubiQ

Imprinted with RubiQ

Imprinted with RubiQ

Development of "HILUCIS"

Background of Development

Nanoimprint technology enables the precise transfer of nanoscale patterns onto resin substrates, playing a vital role in manufacturing optical devices such as displays, smartphone cameras, AR/VR glasses, facial recognition systems, and autonomous driving sensors. These devices require advanced optical components—like waveguides and diffraction gratings—for light propagation, focusing, and diffraction.

Both glass and resin are commonly used materials for these optical components. Among them, UV-curable resins with high refractive indices have gained attention for their ability to expand viewing angles and improve light control performance while offering greater design flexibility and production efficiency. Common fillers used in high-refractive-index resins include titanium oxide and zirconium oxide. Titanium oxide, while exhibiting high optical activity, can cause photodegradation due to its photocatalytic properties under UV light, potentially compromising the resin's durability. On the other hand, zirconium oxide has a lower refractive index compared to titanium oxide, making it challenging to achieve a refractive index above 1.8 while maintaining sufficient light resistance.

We have developed UV-curing resin with a high level of transparency, exceptional light resistance, and superior nanoimprint compatibility, successfully balancing these properties with a high refractive index.

Technical Breakthrough

HILUCIS addresses these challenges by incorporating a proprietary inorganic filler with low optical activity, minimizing yellowing in the near-UV to visible light spectrum. Leveraging Sanyo Chemical's extensive expertise in designing UV-curable resins for display applications, the resin matrix has been carefully optimized, and HILUCIS achieves a high level of transparency, exceptional light resistance, and superior nanoimprint compatibility, successfully balancing these properties with a high refractive index.

| Refractive index | ||||

|---|---|---|---|---|

| ~1.7 | 1.8 | 1.9~ | ||

| Light resistance | Good | ZrO2 type | ||

| ↑ | HILUCIS | |||

| Bad | TiO2 type | |||

Applications of "HILUCIS"

HILUCIS is ideal for:

• Smart glasses and head-mounted displays for AR, VR, and MR (Mixed Reality).

• Sensors for autonomous driving (e.g., LiDAR, 3D sensors) and facial recognition systems.

• Micro-lens arrays and diffractive optical elements (DOEs).

Related Information

Related Products

-

UV Curing Resin

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist