A Highly Functional Textile Containing Wood Powder,"MOC-TEX™"

"MOC-TEX™" is a plant-derived textile with the warmth and charm of wood. It excels in moistureabsorption and desorption and deodorizing properties derived from wood.

SANNOPCO CO., LTD. is an affiliate of SANYO CHEMICALS and a chemical manufacturer of defoamers, dispersants, viscoelasticity regulators, wetting agents, lubricants and mold release agents for various industries and applications.

What is great about SAN NOPCO's "MOC-TEX™".

1

Community Contribution

"MOC-TEX™" is a highly functional textile that reproduces the appearance and flexible texture of genuine leather while containing approximately 80% plant biomass materials including domestic wood.

"MOC-TEX™" is a high-functional textile that reproduces the look and feel of genuine leather while containing approximately 80% plant biomass materials, including domestic wood, and is designed with interface control technology to uniformly disperse wood powder in a high concentration in resin and resin design technology to achieve a flexible texture, contributing to the promotion of use and added value of local wood.

2

Wood-derived functionality

It has the color, aroma, and moisture absorption and desorption as well as aging properties of wood.

3

Environmental friendliness

High biomass (80% plant biomass) contributes to the realization of carbon neutrality.

This textile is made by upcycling unused wood, such as thinned wood, which has no use.

Awards

Received the 23rd Ichikawa Award from the Wood Technological Association of Japan in 2024.

Winner of the Grand Prize at the 24th (2023) Annual Conference of Young Corporate Engineers, Kansai Branch, Wood Technological Association of Japan

Wood Design Award 2022 (Technology), Incentive Award

What is the Wood Design Award?

The Wood Design Award is an awarding system that recognizes and honors outstanding architecture, spaces, products, activities, systems, research, etc., with the aim of reconstructing the quality and value of wood through the power of design.

Example of using SAN NOPCO's "MOC-TEX™"

Pass case

*Produced by Career Consulting Inc

MOC-TEX Pass Case - For Japanese Souvenirs, "Kore-Iiwa" - Traditional Crafts, Japanese Souvenirs (japan-novelty.jp)

Card cases and other miscellaneous goods

Chairs

Cushions

Why did SAN NOPCO develop MOC-TEX™?

Issues of forests and forestry in Japan

The majority of planted forests are 50 years old or older, and there is a need to actively promote the use of domestic timber. Due to the decline of the forestry industry, the number of inadequately maintained forests is increasing, and this has become a social problem from the perspective of land conservation and disaster prevention.

In order to increase the value of forestry, there is a need to make effective use of unused timber such as thinned timber, which is mostly left on forest land.

Aims of "MOC-TEX™" Development

We aimed to develop eco-friendly, ethical, and highly functional textiles using domestic timber, contributing to the promotion of local timber utilization and value-added products.

-By using renewable wood, the use of petroleum-derived raw materials can be reduced, and CO2 emissions and waste can be reduced.

-The moisture absorbing/releasing and deodorizing properties derived from wood can be effectively utilized.

-Wood has been used as a material for general merchandise and furniture for a long time, and it can satisfy consumers who love wood products and furniture.

-This is an environmentally friendly textile that upcycles unused wood such as thinned wood that has no use.

”MOC-TEX™" is a wood-containing textile with a flexible texture, and uses domestic wood for textiles and other applications that have been difficult to apply due to the hardness of wood. This will help promote the use of domestic wood in new applications and enhance the value of the forestry industry.

<Advantages of MOC-TEX™>

-Contributes to solving the social issue of promoting the use of domestic timber.

-The color and aroma of the wood are appealing.

-Contributes to the realization of carbon neutrality because it is plant-derived.

-Excellent moisture release/absorption and deodorizing properties.

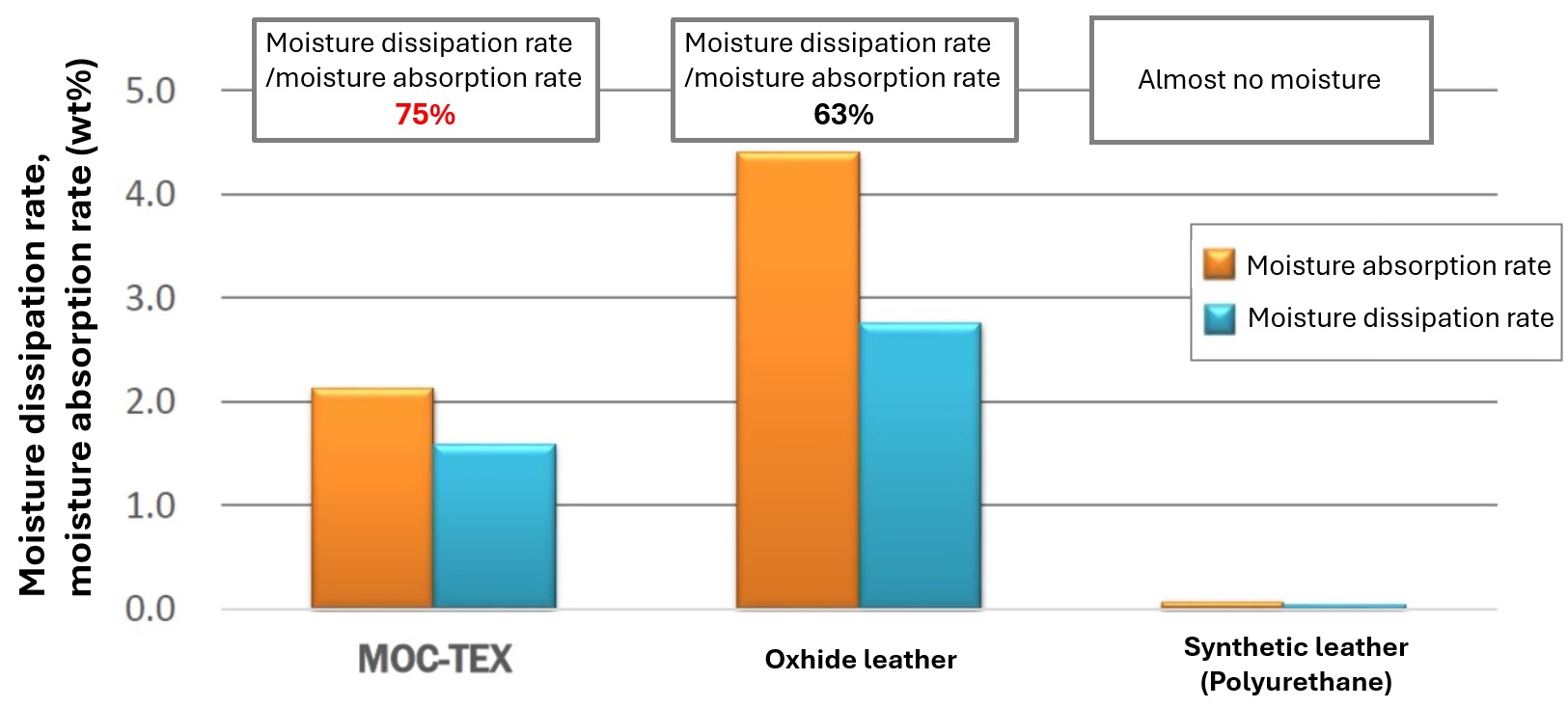

Comparison of "MOC-TEX™" with genuine leather and synthetic leather

| MOC-TEX™ | Real leather | Synthetic leather | |

|---|---|---|---|

| Main raw materials | plant-derived | animal origin | peteroleum derived |

| Plant biomass degree (%) | 80 | 0 | 0 |

| Moisture absorption rate (wt%) | 2.1 | 4.4 | 0.1 |

| Moisture deposition/absorption rate | 75 | 63 | No moisture absorption |

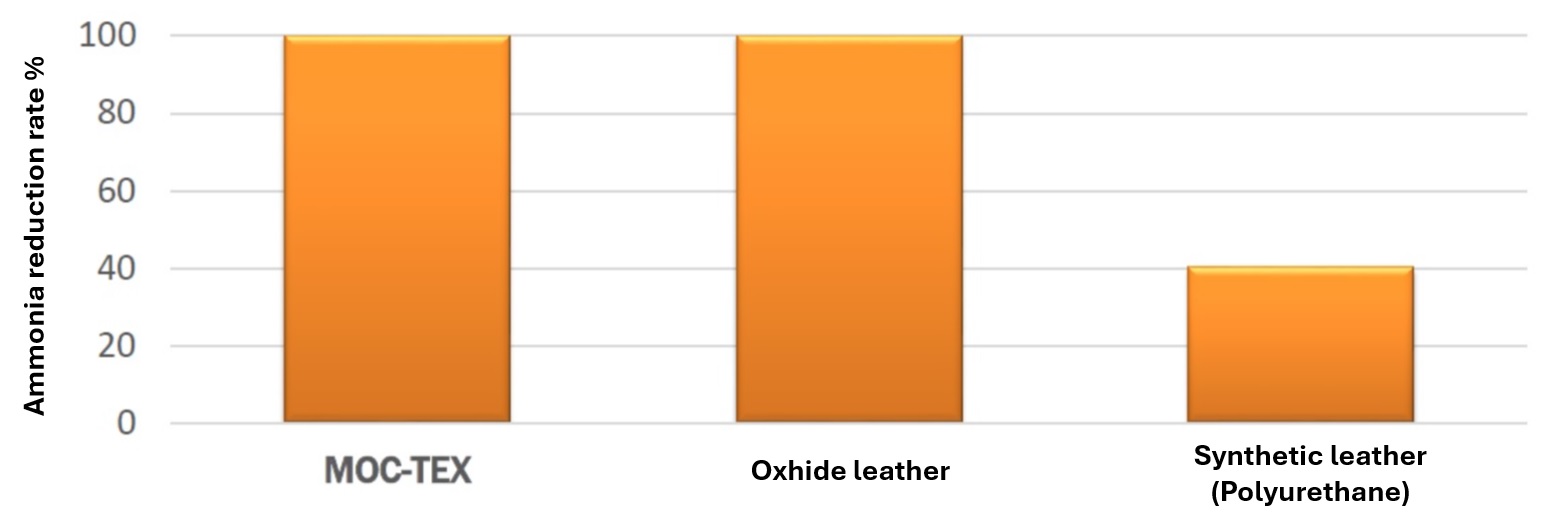

| Deodorizing properties (ammonia reduction rate (%)) | 100 | 100 | 40 |

| Wood texture (aroma, color) | yes | - | - |

Example of SAN NOPCO "MOC-TEX™" development

"MOC-TEX™" Natural

From left to right: Japanese cedar, Japanese bay pine/Japanese cypress = 1/1, Japanese cypress wood powder used

"MOC-TEX™" colored products (pigmented)

Example of SAN NOPCO "MOC-TEX™" performance

Performance data of moisture absorption and desorption

-High moisture absorbency against synthetic leather (wood-derived).

-Although it is inferior to cowhide in moisture absorption, it has a high moisture release rate relative to its moisture absorption rate.

Moisture Absorption/Desorption Test Result

Measurement Procedure

1) Sample preparation: weigh a 64 mm diameter circular sample at 105°C for 2 hours after it has been dried, and then weigh it after 72 hours at 20°C with a relative humidity of 52%.

2) Moisture absorption: Weigh the sample after 24 hours of standing at 20°C and 79% relative humidity, and calculate the percentage of moisture absorption from the difference with 1). 3) Moisture release: Weigh the sample after 72 hours of standing at 52% relative humidity at 20°C.

3) Moisture release: after 24 hours of standing at 20°C and 52% relative humidity, weight was measured, and the moisture release rate and moisture release/absorption rate were calculated from the difference from 2.

Deodorant

Excellent deodorant properties equivalent to cowhide (derived from wood).

Deodorant test results (ammonia reduction rate)

Measurement procedure

In accordance with ISO 17299-2, a 10cm x 10cm sample and 2L of 100ppm ammonia gas are sealed, allowed to stand for 2hrs, and then the ammonia concentration of the gas is measured with a detector tube.

Aging

Left: Before use, Right: After 6 months of use.

Related Information

-

Polyurethane related products

-

Click here for the Polyurethane adhesive "POLYSICK UP" introduction page

Click here for the urethane synthetic wood "SANMODUR" product introduction page

-

Link to SAN NOPCO CORPORATION corporate website

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist.