Polyalkylene glycol-based lubricant"NEWPOL LB, 50HB"

High performance polyalkylene glycol-based lubricant

What's Great about Sanyo Chemical's Polyalkylene Glycol-based Lubricant "NEWPOL LB, 50HB"

1

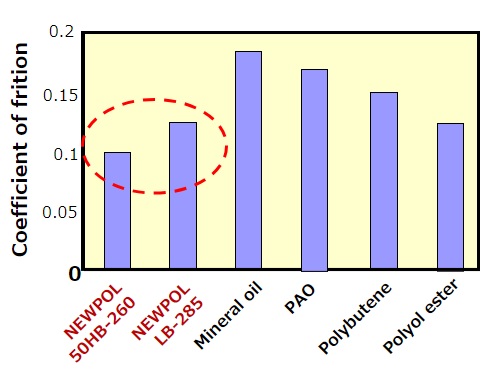

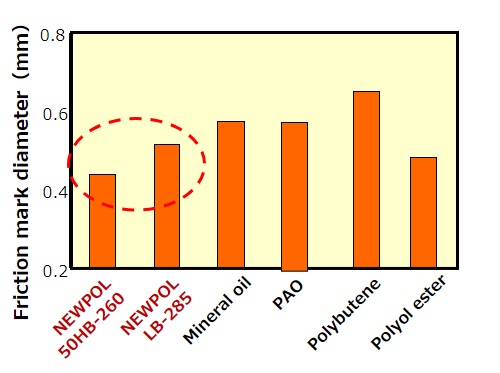

Excellent lubricity

Sanyo Chemical's polyalkylene glycol-based lubricant "NEWPOL LB, 50HB" has a low coefficient of friction, excellent load-bearing capacity, and superior lubricity.

Fig. Comparison of friction coefficients of each lubricant base material

Fig. Comparison of friction mark diameter of each lubricant base material

<Test conditions >

Lubricity (coefficient of friction, wear mark diameter) was evaluated using an oscillating friction and wear test (SRV tester).

Sample: undiluted fluid with kinematic viscosity (40°C) of 45 to 65 mm2/s Specimen: Steel ball (SUJ-2 , Φ10 mm) Steel disk (SUJ-2)

Test conditions: Load 200 N, frequency 50 Hz, vibration width 2 mm, temperature 30°C, time 10 min.

2

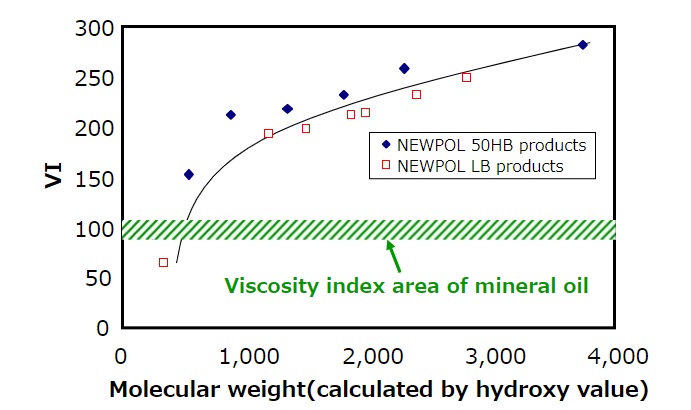

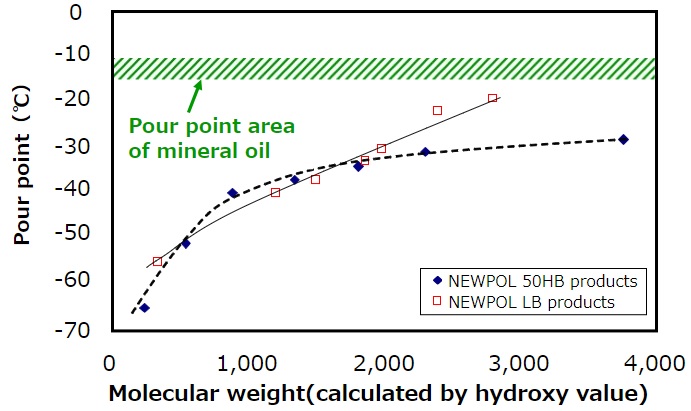

High viscosity index, excellent flowability at low temperatures

- Polyalkylene glycol-based lubricants have a high viscosity index (VI) and little change in viscosity with temperature.

- They have a low flow point and exhibit excellent flowability even at low temperatures.

Relationship between Molecular Weight and Viscosity Index

(VI: Viscosity Index)

Fig. Relationship between molecular weight and pour point

3

High solubility

Soluble in most oils and fats, toluene, benzene, morpholine, alcohols, ketones, glycol ethers and ester solvents.

4

Chemically stable, low contamination, corrosive-free

- Almost no hydrolysis even in the presence of acids and alkalis.

- Almost no sludge such as carbides and gum material is generated.

- Virtually non-corrosive to metals

NEWPOL LB and 50HB, 75H₋90000, and V-10-C are polyoxyalkylene glycol compounds suitable for lubricants.

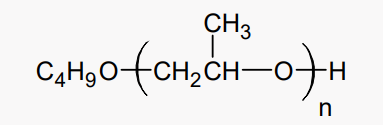

NEWPOL LB products (oil soluble)

Polyoxypropylene butyl ether

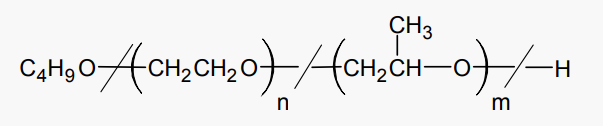

NEWPOL 50HB products (water soluble)

Polyoxyethylene polyoxypropylene butyl ether

NEWPOL 75H-90000 (Water soluble, high molecular weight type)

NEWPOL V-10₋C (water-soluble, high molecular weight type)

Compared to other lubricant base materials, NEWPOL LB&50HB products are characterized by high lubricity, high viscosity index, and low flow point.

Comparison with various base oils

| Item\base oil | NEWPOL LB products (oil soluble Polyether) | NEWPOL 50HB products (water soluble Polyether) | Mineral oil | PAO | Polybutene | Ester |

|---|---|---|---|---|---|---|

| Lubricity | good | good | fair | fair | fair | good |

| Viscosity index | excellent | excellent | fair | good | good | fair |

| Flow point | good | good | fair | good | good | fair |

| Water soluble | poor | good | poor | poor | poor | poor |

| Oil solubility | normal to good | poor | good | good | good | good |

Main Applications

1

Water/glycol-based hydraulic fluid

Most hydraulic fluids used in hydraulic equipment are mineral oil-based hydraulic fluids. However, because they are flammable, there is a risk of fire if they are used near ignition sources. In such locations, water/glycol-based fluids are used, which are based on water, which does not burn, and to which polyalkylene glycol-based lubricants, such as NEWPOL 75H-90000, described below, are added to give the water appropriate viscosity and lubricity.

General characteristics of water/glycol-based hydraulic fluids include flame retardancy, no risk of fire, low flow point, high viscosity index, excellent shear stability, and no stickiness.

Recommended grades: NEWPOL 75H-90000, NEWPOL V-10-C

2

High-temperature lubricants

The use of mineral oil-based lubricants at high temperatures has been considered extremely difficult due to the carbonization and sludging of mineral oil.

Polyalkylene glycol-based lubricants such as NEWPOL LB-300X contain antioxidants and are resistant to oxidative decomposition even when exposed to high temperatures. Even if oxidative decomposition occurs, the products will volatilize or dissolve in the lubricant and produce almost no carbonization or sludge, so they will not burn metals or other materials.

Because of these characteristics, it is used as a base oil for lubricating gear chains and bearings that are operated at high temperatures in cement manufacturing equipment, ceramics manufacturing equipment, glass manufacturing equipment, and plastic processing machines.

Recommended grade: NEWPOL LB-300X, LB-650X, LB-1800X, LB-400XY

3

Lubricating oil for low temperature

Polyalkylene glycol-based lubricants listed below, such as NEWPOL LB-285, have high viscosity index, low viscosity change with temperature change, low flow point, and no wax content, and therefore have excellent starting and lubricating properties at low temperatures.

Because of these features, it is used as a base oil for lubricating oil in hydraulic equipment used in cold climates, ice cream manufacturing equipment, and low-temperature electric motors.

Recommended grades:

NEWPOL LB-285, LB-385, LB-625, LB-1715, LB-3000

NEWPOL 50HB-260, 50HB-400, 50HB-660, 50HB-2000

4

Compressor oil, vacuum pump oil

Polyalkylene glycol-based lubricants such as NEWPOL LB-625 and others listed below have viscosity characteristics suitable for use as compressor oil and vacuum pump oil, have good compatibility with organic substances, and do not carbonize or gum up, so they do not lose lubricating efficiency even after prolonged use.

Because of these characteristics, it is used as a base oil for gas compressor oil, vacuum pump oil, refrigerator oil, compressor oil, etc., in which organic matter, ammonia, or sulfurous acid gas is mixed.

Recommended grades:

Compressor oil

NEWPOL LB-625, LB-1715, LB-3000, LB-300X, LB-650X

NEWPOL 50HB-260, 50HB-400, 50HB-660, 50HB-660

Vacuum pump oil

NEWPO LB-625, LB-1715, LB-3000, LB-300X, LB-650X

5

Gear oil

Polyalkylene glycol-based lubricants listed below, such as NEWPOL LB-385, are suitable as base oils for gear oils because of their extremely good lubricating properties, including oiliness, load bearing capacity, and wear resistance, as well as excellent low-temperature flowability.

Recommended grades:

NEWPOL LB-385, LB-625, LB-1715, LB-3000, LB-300X, LB-650X, LB-1800X, LB-400XY

NEWPOL 50HB-260, 50HB-400, 50HB-660, 50HB-2000, 50HB-5100

6

Hydraulic fluid, automotive brake fluid

Polyalkylene glycol-based lubricants such as NEWPOL 50HB-260 and others listed below are suitable as base agents for hydraulic fluids because they hardly damage rubber and metals, have excellent load-bearing capacity, wear resistance, and shear stability, and have good low-temperature flowability.

Normally, solvents, oiliness enhancers, rust inhibitors, and antioxidants are added to the lubricant to formulate hydraulic fluids and automotive brake fluids.

Recommended grade

Hydraulic fluid: NEWPOL 50HB-260, 50HB-400, 50HB-660

Auto Brake Fluid: NEWPOL 50HB-260

7

Grease

Polyalkylene glycol-based lubricants listed below, such as NEWPOL LB-285, are used as grease base oils because they have viscosity characteristics suitable for greases and excellent dispersibility of solid lubricants.

For example, lithium soap grease blended with lithium soap and high-temperature grease blended with graphite or molybdenum sulfide are prepared.

Recommended grades:

NEWPOL LB-285, LB-1715, LB-3000, LB-650X, LB-1800X

NEWPOL 50HB-2000

NEWPOL 75H-90000

8

Engine Cleaner

Polyalkylene glycol-based lubricants such as NEWPOL LB-285 have good compatibility with gasoline and other fuel oils, and dissolve and remove dirt (sludge) generated inside the engine, and are used as a base for engine cleaners added to fuel oils.

Recommended grades:

NEWPOL LB-285

9

Water-soluble cutting oil

Polyalkylene glycol-based lubricants such as NEWPOL 50HB-55 and others listed below are used as base agents for water-soluble cutting oils (grinding oils) because of their excellent lubricity even under high loads and low foaming properties.

Water-soluble cutting oils suitable for various metals are usually prepared by adding oiliness agents, rust inhibitors, preservatives, chelating agents, etc. to these lubricants. The resulting water-soluble cutting fluids are highly evaluated for their excellent cooling action, almost no metal seizing, long tool life, and high precision finish.

Recommended grades:

NEWPOL 50HB-55, 50HB-260, 50HB-400, 50HB-660, 50HB-2000, 50HB-5100

10

Drawing fluid

Polyalkylene glycol-based lubricants such as NEWPOL 75H-90000 are usually used as drawing fluids without modification because they exhibit excellent lubricity even under high loads, are water soluble, are easily cleaned and removed after drawing, and do not generate carbides like mineral oil when annealed.

Recommended grades: NEWPOL 75H-90000

11

Quenching Lubricants

The polyalkylene glycol-based lubricants listed below, such as NEWPOL 75H-90000, are water soluble and have a viscosity and cloud point (above this temperature, polyoxyalkylene glycol-based lubricants become insoluble in water and separate) suitable for forming adiabatic films that control the quenching cooling rate, and are therefore ), it can be dissolved in water and used as water-soluble quenching oil.

Recommended grades:

NEWPOL 75H-90000, NEWPOL V-10-C

12

Heat media

Polyalkylene glycol-based lubricants such as NEWPOL LB-300X are suitable as heat transfer media because they have extremely low vapor pressure, high viscosity index and small viscosity change with temperature, and do not generate sludge, so the heater surface is not contaminated.

Recommended grades: NEWPOL LB-300X

13

Resin and rubber mold release agent

The following polyalkylene glycol-based lubricants, such as NEWPOL LB-625, are suitable as mold release agents and anti-adhesion agents in the molding of natural rubber, synthetic rubber, urethane rubber, etc., because they hardly act on these materials, withstand vulcanization temperatures well, and do not gum up and become sticky.

It is usually diluted with solvent or water and applied to molds, or kneaded into rubber as an internal mold release agent.

Recommended grades:

NEWPOL LB-625, LB-1715

NEWPOL 50HB-660, 50HB-2000, 50HB-5100

14

Lubricants for Textiles

Polyalkylene glycol-based lubricants listed below, such as NEWPOL 50HB-100, are used as base agents for spinning fluids, etc., because they have excellent fiber lubricating properties, are water soluble and easy to wash off or dilute, and do not tar or yellow during fiber heat treatment processes (stretch processing, heat setting, etc.).

Recommended grades:

NEWPOL 50HB-260, 50HB-660, 50HB-5100, 75H-90000

NEWPOL V-10-C

15

Defoamer

Polyalkylene glycol-based lubricants listed below, such as NEWPOL LB-65, have defoaming properties and have been proven as defoaming agents for lubricating oils, water for steam boilers, antifreeze solutions, latex paints, and as defoaming agents for liquid detergents.

Recommended grades:

NEWPOL LB-65, LB-285, LB-385, LB-625, LB-1715, LB-3000

16

Other

Polyalkylene glycol-based lubricants are used in a variety of lubrication applications, taking advantage of characteristics not found in mineral oils. In addition to lubrication applications, they are used as solvents and diluents for inks and dyes, softeners for leather and paper, plasticizers for resins and fiber finishing agents, surfactant materials, and pharmaceutical base agents such as ointments.

Major Lineup of Sanyo Chemical's Polyalkylene Glycol-based Lubricants "NEWPOL LB, 50HB" Products

Composition data of NEWPOL LB and 50HB products

| Products | Molecular weight (Mn) | Composition | Remarks |

|---|---|---|---|

| NEWPOL LB-65 | 340 | Polyoxyalkylene glycol monoalkyl ether | water-insoluble |

| NEWPOL LB-285 | 1170 | Polyoxyalkylene glycol monoalkyl ether | water-insoluble |

| NEWPOL LB-385 | 1480 | Polyoxyalkylene glycol monoalkyl ether | water-insoluble |

| NEWPOL LB-625 | 1870 | Polyoxyalkylene glycol monoalkyl ether | water-insoluble |

| NEWPOL LB-1715 | 2390 | Polyoxyalkylene glycol monoalkyl ether | water-insoluble |

| NEWPOL LB-3000 | 3070 | Polyoxyalkylene glycol monoalkyl ether | water-insoluble |

| NEWPOL LB-300X | 1170 | Polyoxyalkylene glycol monoalkyl ether (containing antioxidants) | water-insoluble |

| NEWPOL LB-650X | 1870 | Polyoxyalkylene glycol monoalkyl ether (containing antioxidants) | water-insoluble |

| NEWPOL LB-1800X | 2390 | Polyoxyalkylene glycol monoalkyl ether (containing antioxidants) | water-insoluble |

| NEWPOL LB-400XY | 1480 | Polyoxyalkylene glycol monoalkyl ether (containing antioxidants) | water-insoluble |

| NEWPOL 50HB-55 | 300 | Polyoxyethylene polyoxypropylene butyl ether | water-soluble |

| NEWPOL 50HB-260 | 970 | Polyoxyethylene polyoxypropylene butyl ether | water-soluble |

| NEWPOL 50HB-400 | 1340 | Polyoxyethylene polyoxypropylene butyl ether | water-soluble |

| NEWPOL 50HB-660 | 1800 | Polyoxyethylene polyoxypropylene butyl ether | water-soluble |

| NEWPOL 50HB-2000 | 3200 | Polyoxyethylene polyoxypropylene butyl ether | water-soluble |

| NEWPOL 50HB-5100 | 3750 | Polyoxyethylene polyoxypropylene butyl ether | water-soluble |

| NEWPOL 75H-90000 | 14000 | High molecular weight polyoxyalkylene glycol | water-soluble High molecular weight type |

| NEWPOL V-10-C | 22400 | Polymer polyalkylene glycol | water-soluble High molecular weight type |

Physical Properties of NEWPOL LB and 50HB products (1)

| Products | Kinematic viscosity mm2/s | Viscosity index | Flow point | Friction coefficient | Load bearing capacity | |

|---|---|---|---|---|---|---|

| 20℃ | 100℃ | VI | ℃ | 30℃ | kPa | |

| NEWPOL LB-65 | 18 | 2 | 63 | ≦₋50 | 0.198 | 294 |

| NEWPOL LB-285 | 161 | 11 | 192 | ≦₋50 | 0.164 | 343 |

| NEWPOL LB-385 | 190 | 14 | 197 | -43 | 0.162 | 343 |

| NEWPOL LB-625 | 325 | 22 | 212 | -40 | 0.160 | 392 |

| NEWPOL LB-1715 | 980 | 56 | 232 | -38 | 0.133 | 539 |

| NEWPOL LB-3000 | 1665 | 92 | 248 | -30 | 0.120 | 490 |

| NEWPOL LB-300X | 171 | 12 | 190 | ≦₋50 | 0.164 | 343 |

| NEWPOL LB-650X | 344 | 22 | 211 | -40 | 0.160 | 392 |

| NEWPOL LB-1800X | 1014 | 55 | 226 | -38 | 0.133 | 539 |

| NEWPOL LB-400XY | 221 | 16 | 197 | -43 | 0.150 | 441 |

| NEWPOL 50HB-55 | 16 | 2 | 92 | ≦₋50 | 0.178 | 343 |

| NEWPOL 50HB-260 | 119 | 11 | 212 | -49 | 0.149 | 392 |

| NEWPOL 50HB-400 | 192 | 16 | 218 | -48 | 0.141 | 588 |

| NEWPOL 50HB-660 | 343 | 26 | 231 | -45 | 0.134 | 539 |

| NEWPOL 50HB-2000 | 1004 | 69 | 258 | -35 | 0.118 | 588 |

| NEWPOL 50HB-5100 | 2263 | 145 | 282 | -30 | 0.114 | 882 |

| NEWPOL 75H-90000 | 56200 | 2750 | 439 | -3 | - | - |

| NEWPOL V-10-C | - | 3300 | - | -10 | - | - |

Physical Properties of NEWPOL LB and 50HB products (2)

| Products | Surface tention | Specific gravity | Themal expansion coefficient | Flash point | Refractive index |

|---|---|---|---|---|---|

| mN/m (20℃) | (20℃/4℃) | Pa | (0℃) | (20℃) | |

| NEWPOL LB-65 | 32.5 | 0.962 | 8.1x10-4 | 148 | 1.438 |

| NEWPOL LB-285 | 34.5 | 0.991 | 7.6x10-4 | 217 | 1.448 |

| NEWPOL LB-385 | 34.5 | 0.996 | 7.6x10-4 | 220 | 1.449 |

| NEWPOL LB-625 | 34.5 | 1.000 | 7.6x10-4 | 222 | 1.450 |

| NEWPOL LB-1715 | 35.0 | 1.003 | 7.4x10-4 | 228 | 1.452 |

| NEWPOL LB-3000 | - | 1.006 | - | 230 | 1.456 |

| NEWPOL LB-300X | - | 0.996 | 7.6x10-4 | 236 | 1.452 |

| NEWPOL LB-650X | - | 1.002 | 7.6x10-4 | 252 | 1.454 |

| NEWPOL LB-1800X | - | 1.008 | 7.4x10-4 | 258 | 1.455 |

| NEWPOL LB-400XY | - | 0.990 | - | 215 | 1.446 |

| NEWPOL 50HB-55 | 32.5 | 0.991 | 8.1x10-4 | 93 | 1.444 |

| NEWPOL 50HB-260 | 35.8 | 1.038 | 7.8x10-4 | 225 | 1.456 |

| NEWPOL 50HB-400 | 36.4 | 1.046 | 7.9x10-4 | 246 | 1.458 |

| NEWPOL 50HB-660 | 36.8 | 1.052 | 7.4x10-4 | 225 | 1.458 |

| NEWPOL 50HB-2000 | 38.6 | 1.058 | 7.4x10-4 | 233 | 1.460 |

| NEWPOL 50HB-5100 | 38.4 | 1.063 | 7.4x10-4 | 251 | 1.462 |

| NEWPOL 75H-90000 | - | 1.095 | - | 258 | 1.466 |

| NEWPOL V-10-C | - | 1.080 | - | 243 | - |

Sanyo Chemical's Polyalkylene Glycol Lubricant "NEWPOL LB, 50HB" Products Physical Property Data

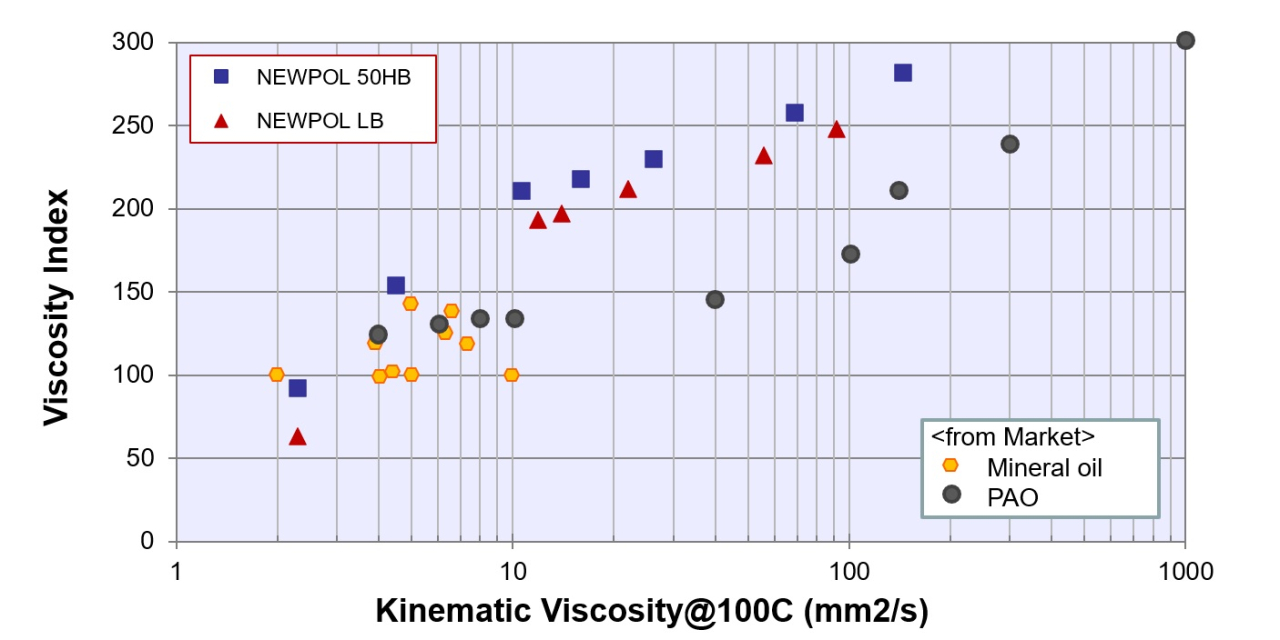

Relationship between lubricant base material and viscosity index

Polyether base materials are located in the high viscosity index region compared to other base materials.

Fig. Relationship between kinematic viscosity coefficient and viscosity index of polyethers, mineral oils, and PAO base materials

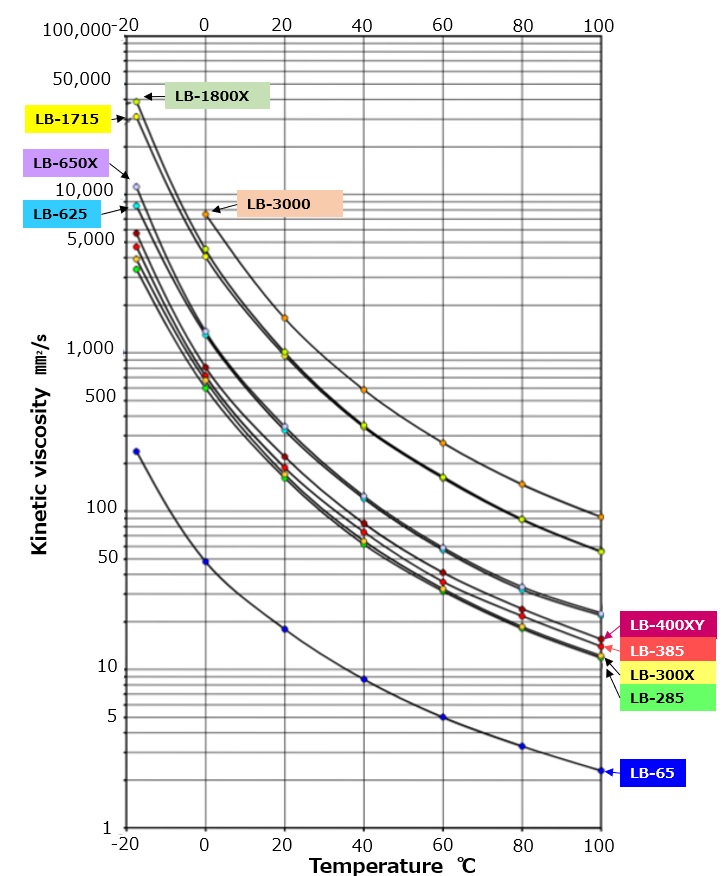

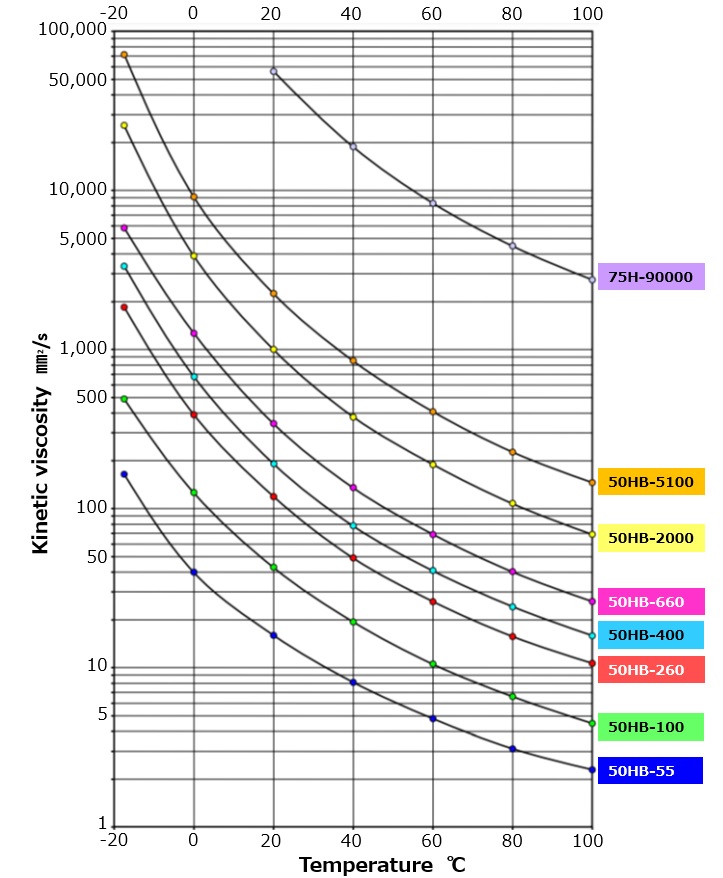

Temperature-Kinematic Viscosity Characteristics

The temperature-kinematic viscosity characteristics of polyoxyalkylene glycol-based lubricants are shown in the figure below.

1

Temperature-Kinematic Viscosity Characteristics of the LB Products

Temperature-Kinematic Viscosity Characteristics (Part 1)

2

50HB Products Temperature-Kinematic Viscosity Characteristics

Temperature-Kinematic Viscosity Characteristics (Part 2)

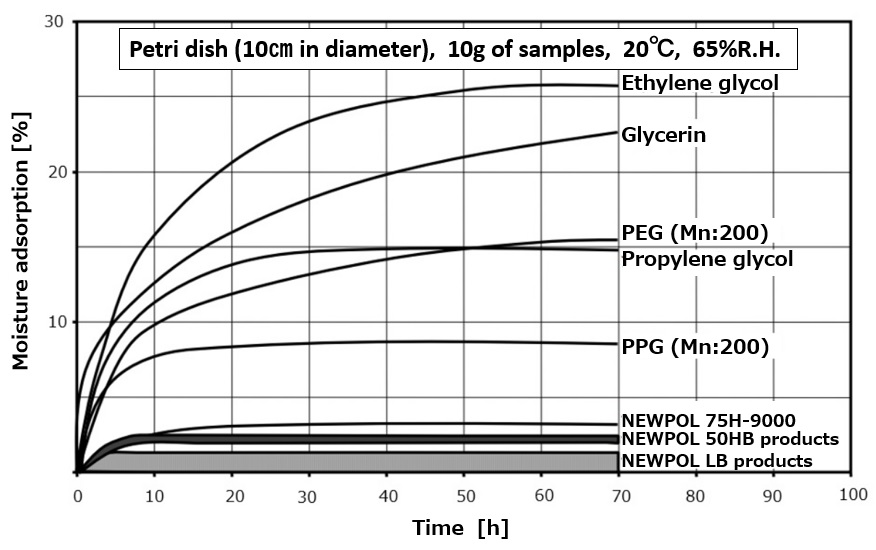

Moisture absorption properties

The moisture absorption characteristics of polyoxyalkylene glycol-based lubricants are shown in the figure below. Note that the moisture absorption characteristics depend on temperature, humidity, and the amount of moisture absorption area and sample.

Fig. Moisture Absorption Characteristics

Solubility

Polyoxyalkylene glycol-based lubricants are soluble in toluene, benzene, morpholine, and most alcohol, ketone, glycol ether, and ester solvents. Solubility in other solvents and fats is shown in the table below.

Solubility of NEWPOL LB-285 and 50HB-660 in various solvents

| NEWPOL LB-285 | NEWPOL 50HB-660 | |

|---|---|---|

| water | insoluble | soluble |

| gasoline | soluble | slightly dissolved |

| kerosene | soluble | insoluble |

| mineral oil | slightly dissolved | slightly dissolved |

| glycerin | insoluble | insoluble |

| ethanediol | insoluble | insoluble |

| propylene glycol | insoluble | soluble |

| diethylene glycol | insoluble | soluble |

| triethanolamine | insoluble | insoluble |

| caster oil | soluble | soluble |

| olive oil | soluble | insoluble |

| camellia oil | soluble | soluble |

| coconut oil | soluble | soluble |

| tall oil | soluble | soluble |

Aqueous solution properties

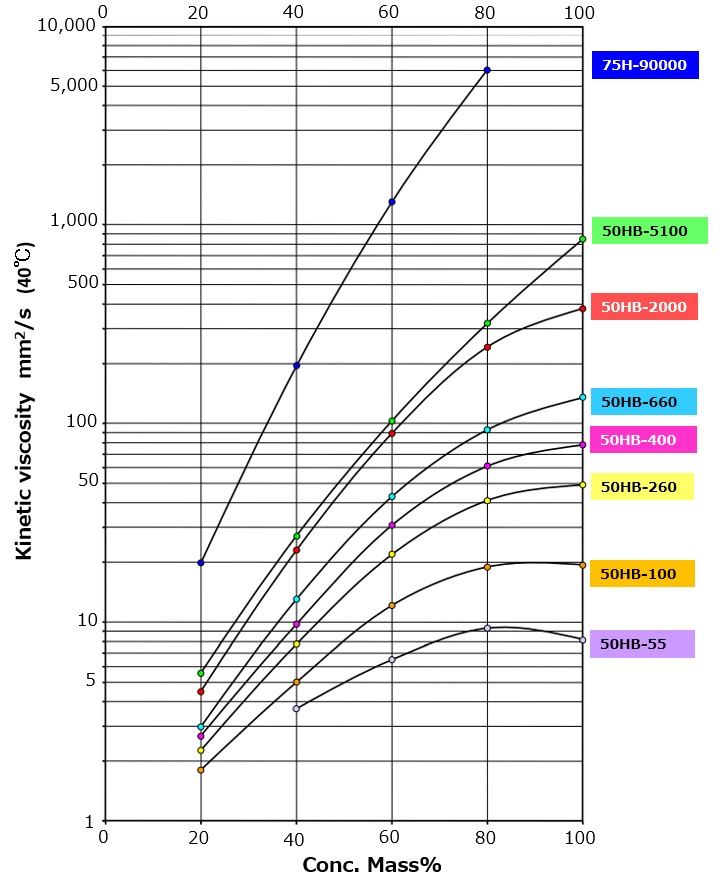

The properties of aqueous solutions of water-soluble polyoxyalkylene glycol lubricants are shown below.

Concentration-Kinematic Viscosity Characteristics of Aqueous Solutions

Fig.

NEWPOL 50HB and 75H-90000 products

Concentration Characteristics of Aqueous Solutions

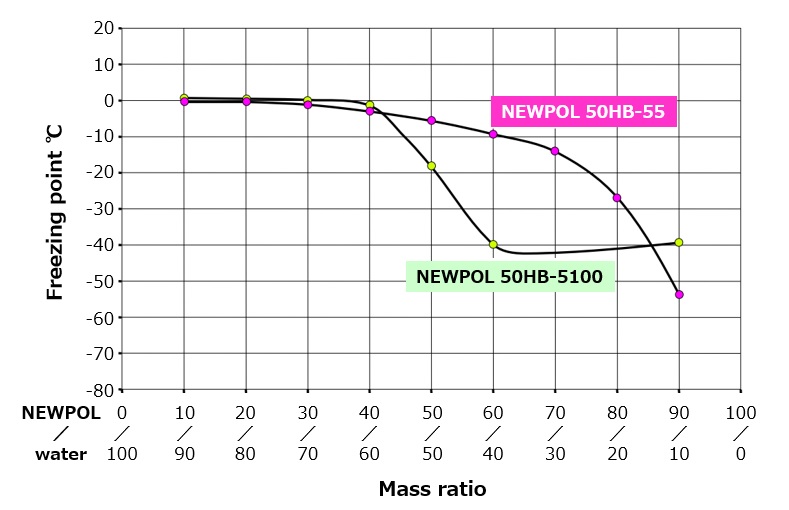

Concentration-Freezing Point Characteristics of Aqueous Solutions

Fig. Concentration-Freezing Point Curve of Aqueous Solution

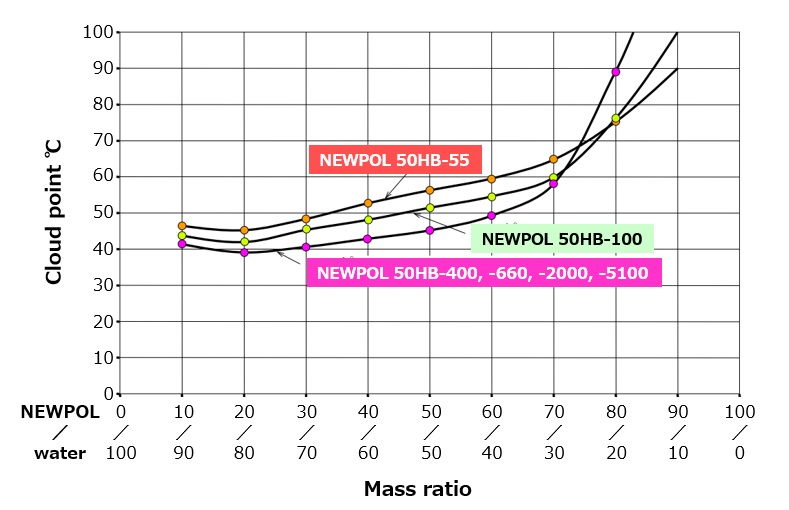

Concentration-cloud point characteristics of aqueous solutions

Fig. Concentration-cloud point curve of aqueous solution

Packaging

List of containers and quantity for each product

| Products | Container (kg) | |

|---|---|---|

| Can | Drum | |

| NEWPOL LB-65 | 17 | 190 |

| NEWPOL LB-285 | 18 | 200 |

| NEWPOL LB-385 | 18 | 200 |

| NEWPOL LB-625 | 18 | 200 |

| NEWPOL LB-1715 | 18 | 200 |

| NEWPOL LB-3000 | 18 | 200 |

| NEWPOL LB-300X | 18 | 200 |

| NEWPOL LB-650X | 18 | 200 |

| NEWPOL LB-1800X | 18 | 200 |

| NEWPOL LB-400XY | 18 | 200 |

| NEWPOL 50HB-55 | 18 | 200 |

| NEWPOL 50HB-260 | 18 | 210 |

| NEWPOL 50HB-400 | 18 | 210 |

| NEWPOL 50HB-660 | 18 | 210 |

| NEWPOL 50HB-2000 | 18 | 210 |

| NEWPOL 50HB-5100 | 18 | 210 |

| NEWPOL 75H-90000 | 18 | 200 |

| NEWPOL V-10-C | 18 | 200 |

Related information

Related products

-

Link to Sanyo Chemical's corporate website

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist