Polyoxyethylene - Polyoxypropylene Block Copolymer, (Pluronic type nonionic surfactant)"NEWPOL PE"

What's great about Sanyo Chemical's polyoxyethylene-polyoxypropylene block copolymer "NEWPOL PE"

1

Pluronic type nonionic surfactant

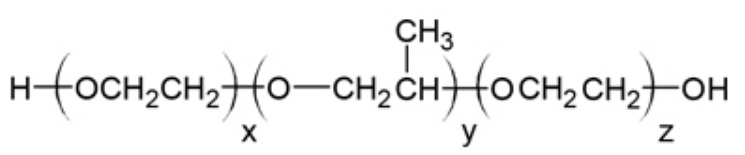

The main component of "NEWPOL PE" is a block copolymer of ethylene oxide (EO) and propylene oxide (PO), a pluronic type nonionic surfactant with a polyoxypropylene chain as a hydrophobic group in the center of the molecular chain and polyoxyethylene chains as hydrophilic groups on both ends.

2

Lineup of products with distinctive features and a wide variety of functions can be added

Depending on the molecular weight of the polyoxypropylene and polyoxyethylene chains, the products are characterized by their appearance (liquid, solid, etc.), foaming and defoaming properties, cleaning power, emulsifying and dispersing power, and dissolving speed in water.

3

A raw material for many chemical products

"NEWPOL PE" products has primary OH groups at both ends of the molecule, so it is also used as a raw material for polyurethane resins and polyester resins.

"NEWPOL PE" products are pluronic type non-ionic surfactants (polyoxyethylene polyoxypropylene block polymer) that are used in a variety of fields.

Structrural formula of "NEWPOL PE" products

Pluronic type nonionic surfactant (polyoxyethylene polyoxypropylene block copolymer)

Main applications of "NEWPOL PE" products

"NEWPOL PE" products is used in a variety of applications due to the following features.

As a nonionic surfactant, it exhibits surfactant performance even in the presence of acids, alkalis, and metallic salts, and because it is polyether-based, it does not hydrolyze.

It has relatively low foaming and good foam breaking properties among nonionic surfactants.

Dissolves in water at any ratio as long as the temperature is below the cloud point.

1

Raw materials for detergent

"NEWPOL PE" products can be used as raw materials for household laundry detergents, furniture detergents, dishwasher detergents, car wash detergents, and toilet aromatic detergents. NEWPOL PE-68, PE-78, and PE-108, which are solid at room temperature, have low hygroscopicity and can be formulated into powder detergents. Examples of formulations for dishwasher detergents are shown below.

<Example of formulation for automatic dishwasher detergent(mass%) >

NEWPOL PE-62: 2%

Sodium metasilicate: 20%

Sodium sulfate decahydrate (Glauber's salt): 50%

Sodium carbonate: 27.9%

CMC: 0.1%

Total: 100%

2

Textiles

"NEWPOL PE" products can be used as raw materials for scouring agents, compound fiber oils, antistatic agents, and glue removers.

3

Cleaning agent for machinery and metal parts

"NEWPOL PE" products can be used as raw materials for acid cleaning agents, alkali cleaning agents, electrolytic cleaning agents, and spray cleaning agents. Examples of formulations for corrosion resistance to steel plates in hydrochloric acid and sulfuric acid baths and alkaline soaking detergents are shown below.

NEWPOL PE-34, PE-61, PE-62, PE-64, PE-71, PE-74, and PE-75 have low foaming properties and are suitable as metal cleaning agents.

They are practically non-corrosive to metals, and when used for acid cleaning, they exhibit anti-corrosion properties for steel plates.

<Example of alkaline soaking detergent formulation(mass%)>

NEWPOL PE-62 : 6%

Sodium metasilicate: 32%

Sodium phosphate: 20.5%

Soda ash: 14%

Sodium bicarbonate: 11.5%

LAS (active ingredient 60%): 16%

Total: 100%

Corrosion protection for polished steel plate in hydrochloric acid bath

| Surfactant | Corrosion rate gm-2h-1 |

Corrosion resistance % |

|

|---|---|---|---|

| Product name | Additive amount wt% |

||

| NEWPOL PE-61 | 0.05 | 14.1 | 65.6 |

| NEWPOL PE-64 | 0.05 | 14.4 | 64.9 |

| NEWPOL PE-68 | 0.05 | 15.5 | 62.2 |

| Sodium lauryl sulfate | 0.05 | 23.2 | 43.4 |

| None (Control) | 41.0 | - | |

[Test Method]

Polished steel plate (4 x 30 x 50 mm) immersed in 15 mass% hydrochloric acid bath at 40°C for 6 hours

Corrosion protection for polished steel plate in sulfuric acid bath

| Surfactant | Corrosion rate g m-2h-1 |

Corrosion resitance % |

|

|---|---|---|---|

| Product name | Additive amount wt% |

||

| NEWPOL PE-61 | 0.05 | 21.0 | 85.5 |

| NEWPOL PE-64 | 0.05 | 15.0 | 89.7 |

| Sodium lauryl sulfate | 0.05 | 109.0 | 24.8 |

| Sodium dodecyl benzene | 0.05 | 90.0 | 37.9 |

| None (Control) | 145.0 | - | |

[Test Method]

Polished steel plate (4 x 30 x 50 mm) soaked in a 20 mass% sulfuric acid bath at 60°C for 6 hours.

4

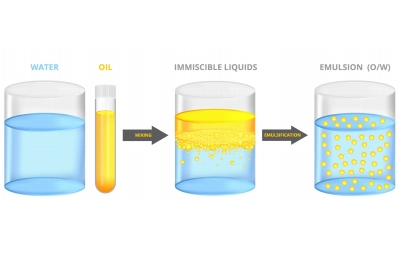

Emulsifiers and dispersants

"NEWPOL PE" products can be used as emulsifiers for emulsion polymerization, emulsion stabilizers and pigment dispersants for latex paint, emulsifier for silicone, and emulsifier for agricultural chemicals.

When used as an emulsifier for emulsion polymerization of vinyl acetate, NEWPOL PE-64 and PE-68 can be used together to produce resin emulsions with good stability and excellent flowability without using protective colloids. The following are examples of formulations as emulsifiers for emulsion polymerization and as emulsion stabilizers and pigment dispersants for latex paint.

<Formulation example of emulsifier for emulsion polymerization (mass%)>

Vinyl acetate monomer: 50%

Potassium persulfate : 0.3%

NEWPOL PE-64 : 2.5%

NEWPOL PE-68 : 2.5%

Water : 44.7%

Total: 100%

<Example of latex paint formulation(mass%)>

Polyvinyl acetate: 1%

NEWPOL PE-68 (20% aqueous solution): 0.5%

CMC (5% aqueous solution): 16.5%

Potassium carbonate (50% aqueous solution): 0.01%

Pigment: 72.99%

Total: 100%

5

Additives for synthetic resins

When blended with synthetic resins, it is effective as an antistatic agent, plasticizer, and mold release agent.

The degree of effectiveness depends on the type of resin and the amount added. Please confirm in advance the optimum type and amount to be added according to the applicable resin.

The user is responsible for determining the suitability and safety of the product for each application.

The following are examples of formulations of sanitizing detergents for use in food processing plants.

Main lineup of Sanyo Chemical's pluronic type nonionic surfactant "NEWPOL PE" products

Properties of pluronic type nonionic surfactants "NEWPOL PE" (1)

| Average molecular weight | Appearance (20±5℃) |

Color scale (Hazen) |

||

|---|---|---|---|---|

| Polyoxypropylene chain portion | Total | |||

| NEWPOL PE-34 | Approx.1,000 | Approx.1,700 | Colorless liquid | 10 |

| NEWPOL PE-61 | Approx.1,750 | Approx.2,000 | Colorless liquid | 10 |

| NEWPOL PE-62 | Approx.1,750 | Approx.2,400 | Colorless liquid | 10* |

| NEWPOL PE-64 | Approx.1,750 | Approx.3,100 | Colorless paste | 10 |

| NEWPOL PE-68 | Approx.2,000 | Approx.8,000 | White flakes | 10 |

| NEWPOL PE-71 | Approx.2,000 | Approx.2,200 | Colorless liquid | 10 |

| NEWPOL PE-74 | Approx.2,000 | Approx.3,100 | Colorless paste | 10 |

| NEWPOL PE-75 | Approx.2,000 | Approx.3,500 | Colorless paste | 10 |

| NEWPOL PE-78 | Approx.2,000 | Approx.9,400 | White flakes | 10* |

| NEWPOL PE-108 | Approx.3,250 | Approx.16,000 | White flakes | 10* |

Properties of pluronic type nonionic surfactants "NEWPOL PE" (2)

| pH (1wt% aq.) |

Melting point ℃ |

Freezing point ℃ |

Cloud point |

Specific gravity mPa・s |

|

|---|---|---|---|---|---|

| NEWPOL PE-34 | 6.3 | - | -1 | 63 | 1.03 |

| NEWPOL PE-61 | 6.0 | - | -30 | 24 | 1.00 |

| NEWPOL PE-62 | 6.0 | - | -4 | 30 | 1.03 |

| NEWPOL PE-64 | 6.1 | - | 15 | 59 | - |

| NEWPOL PE-68 | 7.0 | 53 | - | 113 * | - |

| NEWPOL PE-71 | 6.0 | - | -30 | 21 | 1.00 |

| NEWPOL PE-74 | 6.2 | - | 15 | 56 | - |

| NEWPOL PE-75 | 6.1 | - | 17 | 69 | - |

| NEWPOL PE-78 | 7.0 | 54 | - | 110 * | - |

| NEWPOL PE-108 | 7.2 | 57 | - | 105 * | - |

Properties of the pluronic type non-ionic surfactants "NEWPOL PE" (3)

| Viscosity mPa・s (40℃) |

Kinematic viscosity mm/s2 (100℃) |

Surface tention mN/m (20℃) |

Foaming property* mm (20℃) |

|||||

|---|---|---|---|---|---|---|---|---|

| 0.1wt% aq. | 1.0wt% aq. | 0.1wt% aq. | 1.0wt% aq. | |||||

| Immediately after | After 5min | Immediately after | After 5min | |||||

| NEWPOL PE-34 |

100 | - | 48.8 | 45.3 | 22 | 2 | 24 | 17 |

| NEWPOL PE-61 |

140 | - | 45.4 | 42.0 | 18 | 0 | 9 | 0 |

| NEWPOL PE-62 |

200 | - | 48.0 | 45.0 | 21 | 4 | 25 | 5 |

| NEWPOL PE-64 |

300 | - | 48.0 | 45.6 | 28 | 7 | 34 | 10 |

| NEWPOL PE-68 |

- | 360 | 51.2 | 49.6 | 48 | 12 | 53 | 14 |

| NEWPOL PE-71 |

180 | - | 44.8 | 42.1 | 8 | 0 | 5 | 0 |

| NEWPOL PE-74 |

450 | - | 46.8 | 45.8 | 30 | 7 | 46 | 8 |

| NEWPOL PE-75 |

490 | - | 47.0 | 45.8 | 32 | 13 | 45 | 29 |

| NEWPOL PE-78 |

- | - | 49.0 | 46.4 | 48 | 12 | 55 | 15 |

| NEWPOL PE-108 |

- | 2200 | 47.2 | 45.0 | 48 | 12 | 53 | 15 |

Container size

| Bag | Can | Drum | |

|---|---|---|---|

| NEWPOL PE-34 | - | 18kg | 200kg |

| NEWPOL PE-61 | - | 18kg | 200kg |

| NEWPOL PE-62 | - | 18kg | 200kg |

| NEWPOL PE-64 | - | 18kg | 200kg |

| NEWPOL PE-68 | 20kg | - | - |

| NEWPOL PE-71 | - | 18kg | 200kg |

| NEWPOL PE-74 | - | 18kg | 200kg |

| NEWPOL PE-75 | - | 18kg | 200kg |

| NEWPOL PE-78 | 20kg | - | - |

| NEWPOL PE-108 | 20kg | 18kg | - |

Please be sure to read the "Safety Data Sheet" (SDS) for each product and sub-material (chemical) before handling the products listed on this website. The SDS can be obtained from here. https://www.sanyo-chemical.co.jp/products/en/sds/

Related Information

Related Products

-

Link to Sanyo Chemical's corporate website

Related topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist