Nonionic Surfactants Catalog

- What is a Surfactant?

- Sanyo Chemical's nonionic surfactant map

- Physycal properties of nonionic surfactants

- Synthetic alcohol-based nonionic surfactant (low foaming)

- Synthetic alcohol-based nonionic surfactant (primary alcohol)

- Synthetic alcohol-based nonionic surfactant (secondary alcohol)

- Natural alcohol-based nonionic surfactants (C12-C14)

- Natural alcohol-based nonionic surfactants (C16-C18)

- Natural alkylamine nonionic surfactant

- Fatty acid ester nonionic surfactant (PEG ester type)

- Fatty acid ester nonionic surfactant (sorbitan-based)

- Pluronic type nonionic surfactant

What is a Surfactant?

First, an interface is a boundary surface that exists between two substances with different properties, and interfaces exist between liquids and solids, liquids and liquids, and liquids and gases.

Surfactants enhance performance by performing functions such as washing, emulsifying, dispersing, wetting, and penetrating at this interface.

Interface = a boundary surface that exists between two substances with different properties

Liquid and solid: cup and coffee, machine and lubricant

Liquid and liquid: water and oil

Liquid and gas: seawater and air, soap bubbles

Examples of roles of surfactants

Cleaning ・・・ Removing dirt

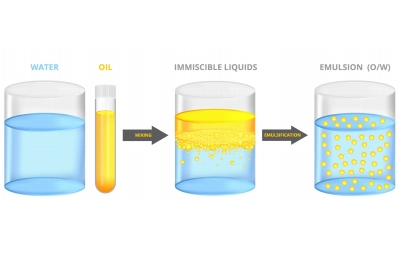

Emulsification ・・・ Dispersion ・・ Making unmixable things easier to mix

Wetting / Penetration ・・・ Makes wetting and soaking easier

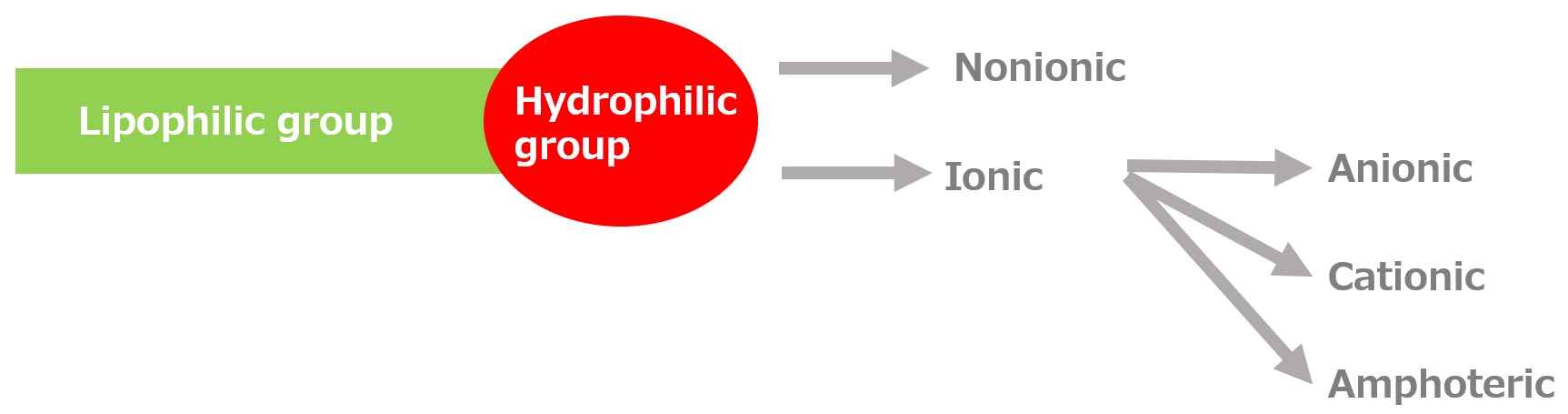

Basic structure of a surfactant

-Surfactants have different structures in their molecules with different properties: lipophilic groups (oil-fitting parts) and hydrophilic groups (water-fitting parts).

-Surfactants are broadly classified into four types according to the structure of the hydrophilic group: nonionic, anionic, cationic, and amphoteric (having both anionic and cationic groups).

| Type of surfactant | Feature | Main application | Composition example |

|---|---|---|---|

| Nonionic surfactant | -Hydrophilic and hydrophobic balance can be easily adjusted -Excellent emulsification and solubilization -Low lather -Susceptible to temperature but not to pH | -Clothing detergent -Emulsifiers and solubilizers -Dispersant -Metalworking oil | -Polyoxyethylene alkyl ether etc. |

| Anionic surfactant | -Excellent emulsification and dispersibility -Good lather -Temperature insensitive | -Clothing Detergent -Shampoo -Body soap | -Alkyl benzene sulfonate -Alkyl ether sulfates etc. |

| Cationic surfactant | -Adsorption to fibers -Antistatic effect -Bactericidal | -Hair rinse -Fabric softener for clothes -Disinfectant | -Didecyldimethylammonium methyl sulfate |

| Amphoteric surfactant | -Mild on skin -Excellent solubility in water -Synergistic with other actives | -Shampoo -Body soap -Kitchen detergent | -Alkyl di-aminoethyl hydrochloride glycine -Lauryl aminopropionic acid sodium sodium -Dimethylstearyl betaine -Coconut oil fatty acid amidopropyl betaine |

Introduction Video of Surfactant Functions

It consists of seven short movies for each function.

0:00 Introduction of surfactants functions

0:16 Part1 Washability

1:00 Part2 Permeability

2:10 Part3 Dispersion

2:55 Part4 Foaming porperties

3:25 Part5 Defoaming properties

3:39 Part6 Smoothness

4:20 Part7 Antibacterial properties

Sanyo Chemical's Nonionic Surfactant Map

Sanyo Chemical's main lineup of nonionic surfactants are classified by strain (structure and hydrophobic group raw materials) and HLB as shown in the table below.

| HLB | Pluronic type | Synthetic alcohol type | Natural alcohol type | Fatty acid ester | |||

|---|---|---|---|---|---|---|---|

| NEWPOL | SEDORAN | NAROACTY | SANNONIC | EMULMIN C12~C14 |

EMULMIN C16~C18 |

IONET | |

| 2~3 | PE-61, PE-71 |

S-85 | |||||

| 4~5 | PE-62 | S-80, S-60V |

|||||

| 6~7 | CL-20 | DL-200 | |||||

| 8~9 | PE-64, PE-71 |

CL-40 ID-40 |

SS-30 | DO-400, S-20 |

|||

| 10~11 | PE-75 | CL-50 | SS-50 | DO-600 | |||

| 12 | FF-180, FF-200 |

CL-70 ID-60 |

SS-70, FN-80 |

NL-70 | MO-400 | ||

| 13 | FF-210 | CL-85, CL-95 CL-100, ID-80 |

SS-90, FN-100 |

FL-80,FL-100, HL-80,HL-100 LS-80,NL-100 |

110 | DO-1000 | |

| 14 | FF-220 | CL-120 | FN-140 | LS-90, NL-90, NL-100 |

140 | MO-600 | |

| 15 | PE-108, PE-128 |

CL-140, CL-160 |

SS-120 | NL-110 | 180 | T-60V, T-80V |

|

| 16 | PE-68 PE-78 |

CL-200 | 200, 240 |

||||

| 17~18 | CL-400 | T-20C | |||||

Physical Properties of Sanyo Chemical's Representative Nonionic Surfactants

Synthetic alcohol-based nonionic surfactant (low foaming)

"SEDORAN FF" products are higher alcohol nonionic surfactants with low foaming and excellent cleaning power.

Click here for the "SEDORAN FF" page.

Synthetic alcohol-based nonionic surfactant (low foaming)

| Appearance *1 | Cloud point | Flow point ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | ||||

| SEDORAN FF-180 | liquid | 2wt% | 31 | ≦0 | 31.0 | 0.5 | 0.0 |

| SEDORAN FF-200 | liquid | 2wt% | 44 | 10 | 33.2 | 10.8 | 7.0 |

| SEDORAN FF-210 | liquid | 2wt% | 53 | 10 | 33.0 | 13.5 | 10.8 |

| SEDORAN FF-220 | paste | 2wt% | 73 | 20~30 | 33.3 | 10.8 | 7.0 |

| SEDORAN SF-506 | liquid | 10wt% | 17 | ≦-5 | 30.2 | 4.9 | 2.7 |

| SANNONIC TN-1265 | liquid | 10wt% in 25%BDG *4 | 34 | ≦-20 | 30.8 | 5.3 | 2.6 |

Synthetic alcohol-based nonionic surfactant (primary alcohol)

NAROACTY CL

"NAROACTY CL" products have excellent surface tension lowering ability, detergency, and emulsifying power, and are widely used as a raw material for various detergents for kitchen, clothing, and residential use, and as detergents, emulsifiers, dispersants, and wetting agents in the textile, paper, pulp, synthetic resin, and metal industries.

SANNONIC FN

"SANNONIC FN" are synthetic higher alcohol-based nonionic surfactants with good low-temperature flowability. Compared to other nonionic surfactants with similar cloud point, it has a low flow point, which makes it easy to transfer and compound.

They can be widely used as a raw material for kitchen detergents, clothing detergents, and household detergents, as well as for detergents, emulsifiers, dispersants, and wetting agents in the textile industry, paper and pulp industry, plastics industry, metal industry, and other industrial fields.

Synthetic alcohol-based nonionic surfactant (primary alcohol)

| Appearance *1 | HLB | Cloud point | Flow point (Fluidization point) ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | |||||

| NAROACTY CL-40 | liquid | 8.9 | 2wt% | ≦20 | (11) | 27.5 | 3.2 | 1.6 |

| NAROACTY CL-50 | liquid | 10.0 | 2wt% | ≦20 | (11) | 28.2 | 2.1 | 1.1 |

| NAROACTY CL-70 | liquid | 11.7 | 2wt% | ≦20 | (-7) | 29.8 | 13.2 | 10.0 |

| NAROACTY CL-85 | liquid | 12.6 | 2wt% | 41 | (2) | 30.6 | 33.2 | 27.4 |

| NAROACTY CL-95 | liquid | 13.1 | 2wt% | 54 | (8) | 31.5 | 29.0 | 16.8 |

| NAROACTY CL-100 | liquid | 13.3 | 2wt% | 64 | (12) | 32.1 | 25.1 | 22.2 |

| NAROACTY CL-120 | paste | 14.1 | 2wt% | 80 | (22) | 34.3 | 25.4 | 23.1 |

| NAROACTY CL-140 | solid | 14.7 | 2wt% | 93 | (31) | 36.4 | 27.8 | 19.5 |

| NAROACTY CL-160 | solid | 15.2 | 2wt% | 99 | 36 | 37.8 | 34.4 | 22.8 |

| NAROACTY CL-200 | solid | 16.0 | 2wt% | >100 | 42 | 41.0 | 25.4 | 22.5 |

| NAROACTY CL-400 | flake | 17.8 | 2wt% | >100 | 52 | 48.6 | 22.2 | 20.0 |

| NAROACTY ID-40 | liquid | 8.1 | 2wt% | ≦20 | (≦-10) | 27.5 | 1.1 | 0.0 |

| NAROACTY ID-60 | liquid | 12.5 | 2wt% | 43 | (-7) | 27.4 | 36.3 | 11.1 |

| NAROACTY ID-70 | liquid | 13.2 | 2wt% | 61 | (5) | 27.8 | 33.4 | 11.2 |

| SANNONIC FN-80 | liquid | - | 2wt% | 35 | (≦-20) | 29.8 | 28.4 | 21.8 |

| SANNONIC FN-100 | liquid | - | 2wt% | 56 | (≦-10) | 31.0 | 30.0 | 23.2 |

| SANNONIC FN-140 | liquid | - | 2wt% | 79 | (≦5) | 36.3 | 41.1 | 24.2 |

Synthetic alcohol-based nonionic surfactant (secondary alcohol)

"SANNONIC SS" products are an ethylene oxide adduct of secondary alcohols and has excellent penetrating properties.

Synthetic alcohol-based nonionic surfactant (secondary alcohol)

| Appearance *1 | HLB | Cloud point | Flow point ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | |||||

| SANNONIC SS-30 | liquid | 8.0 | 1wt% | ≦20 | -56 | 28.6 | 1.1 | 0.0 |

| SANNONIC SS-50 | liquid | 10.5 | 1wt% | ≦20 | -27 | 28.2 | 15.8 | 12.6 |

| SANNONIC SS-70 | liquid | 12.1 | 2wt% | 33 | 0 | 28.6 | 39.5 | 25.5 |

| SANNONIC SS-90 | liquid | 13.2 | 2wt% | 56 | 8 | 29.8 | 51.6 | 30.3 |

| SANNONIC SS-120 | liquid | 14.5 | 2wt% | 83 | 17 | 31.8 | 57.4 | 40.5 |

Natural alcohol-based nonionic surfactants (C12-C14)

The "EMULMIN FL and HL" products have excellent detergency and dispersing power, and are widely used as raw materials for kitchen detergents, clothing detergents, and household detergents, as well as detergents, emulsifiers, dispersants, wetting agents, and other applications in the textile, paper/pulp, plastics, and metal industries. The following products are also available.

Click here for the introduction page of "EMULMIN FL and HL"

Natural alcohol-based nonionic surfactants (C12-C14)

| Appearance *1 | HLB | Cloud point | Flow point (Fluidization point) ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | |||||

| EMULMIN LS-80 | solid~paste | 13.1 | 2wt% | 70 | (20) | 30.4 | 44.6 | 20.3 |

| EMULMIN LS-90 | solid~paste | 13.6 | 2wt% | 82 | (21) | 32.1 | 44.6 | 35.1 |

| EMULMIN HL-100 | liquid | - | 2wt% | 61 | -17 | 33.0 | 41.9 | 33.8 |

| EMULMIN FL-80 | liquid | - | 2wt% | 52 | -18 | 30.8 | 44.6 | 26.8 |

| EMULMIN FL-100 | liquid | - | 2wt% | 61 | -11 | 31.4 | 30.5 | 24.2 |

| EMULMIN NL-70 | liquid | 12.4 | 1wt% | 58 | (17) | 29.2 | 47.8 | 26.5 |

| EMULMIN NL-80 | liquid | 13.1 | 1wt% | 72 | (19) | 30.0 | 40.0 | 30.0 |

| EMULMIN NL-90 | liquid | 13.6 | 1wt% | 84 | (21) | 31.7 | 40.5 | 31.1 |

| EMULMIN NL-100 | solid | 14.0 | 1wt% | 91 | (22) | 33.5 | 41.1 | 30.3 |

| EMULMIN NL-110 | solid | 14.4 | 1wt% | 97 | (25) | 34.9 | 42.6 | 35.8 |

| EMULMIN CS-100W | liquid | - | 2wt% in 5%NaCl | 78 | 15 | 37.0 | 37.4 | 29.0 |

| EMULMIN AF-101 | liquid | - | 2wt% | 65 | 5 | 33.9 | 36.3 | 23.9 |

Natural alcohol-based nonionic surfactants (C16-C18)

"EMULMIN No." products are polyoxyethylene alkyl ether type nonionic surfactant made by addition polymerization of ethylene oxide to natural higher alcohols (mainly oleyl alcohol and cetyl alcohol).

In addition to being used as a raw material for household detergents, it is also used as emulsifiers, dispersants, wetting agents, and detergents in the cosmetics industry, metal industry, synthetic resin industry, agrochemical industry, textile industry, and other industrial fields.

Natural alcohol-based nonionic surfactants (C16-C18)

| Appearance *1 | HLB | Cloud point | Flow point (Fluidization point) ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | |||||

| EMULMIN 40 | liquid | 8.0 | 2wt% | ≦20 | (8) | - | - | - |

| EMULMIN 50 | liquid | 9.0 | 2wt% | ≦20 | (15) | 31.2 | 2.1 | 1.6 |

| EMULMIN 110 | paste | 13.2 | 1wt% | 78 | 25 | 33.7 | 26.3 | 19.7 |

| EMULMIN 140 | paste~solid | 14.2 | 2wt% | 91 | 30 | 36.1 | 29.5 | 20.8 |

Natural alkylamine nonionic surfactant

Compared to other nonionic surfactants, the polyoxyalkylene alkylamine nonionic surfactant "PUREMEEL EP-300S" exhibits excellent surface tension lowering ability against oil and grease even at low concentrations, and demonstrates high cleaning power against oil and grease stains.

Click here for the "PUREMEEL EP-300S" introduction page.

Natural alkylamine nonionic surfactant

| Appearance *1 | pH | Cloud point | Flow point (Fluidization point) ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | |||||

| PUREMEEL EP-300S | liquid | 9.0 | 1wt% | 81 | ≦0 | 44.7 | 23.7 | 15.3 |

| PUREMEEL CPE-100 | liquid | 10.0 | 1wt% | 75 | N.D. | 37.8 | 47.6 | 23.2 |

| PUREMEEL EP-360 | liquid | 10.0 | 2wt% in 5%NaCl | 75 | (9) | 44.7 | 36.3 | 24.0 |

| PUREMEEL CCS-80 | liquid | 10.0 | 2wt% in 5%NaCl | 77 | -15 | - | - | - |

| PUREMEEL CF-60 | liquid | 10.5 | 2wt% | 76 | (≦0) | - | - | - |

| PUREMEEL PPE-103 | liquid | 10.0 | 2wt% in 5%NaCl | 80 | (≦5) | 43.3 | 37.9 | 20.8 |

Fatty acid ester nonionic surfactant (PEG ester type)

"IONET D" products are fatty acid diesters of polyethylene glycol, and "IONET M" products are fatty acid monoesters of polyethylene glycol. They are used as emulsifiers, dispersants, and smoothing agents in a wide range of industrial fields, including the agrochemical industry, metal industry, cosmetic industry, paper and pulp industry, and fiber industry.

Fatty acid ester nonionic surfactant (PEG ester type)

| Appearance *1 | HLB | Cloud point | Flow point ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | |||||

| IONET MO-200 | liquid | 8.4 | 2wt% | ≦20 | ≦10 (melting point) | 31.6 | 0.0 | 0.0 |

| IONET MO-400 | liquid | 11.8 | 2wt% | ≦20 | 13~18 (melting point) | 35.0 | 3.7 | 3.2 |

| IONET MO-600 | liquid | 13.7 | 2wt% | 53 | 15 (melting point) | 35.1 | 20.0 | 18.4 |

| IONET DO-400 | liquid | 8.4 | 2wt% | ≦20 | 5 (melting point) | 35.9 | 0.0 | 0.0 |

| IONET DO-600 | liquid | 10.4 | 2wt% | ≦20 | 20~21 (melting point) | 35.6 | 0.0 | 0.0 |

| IONET DO-1000 | liquid | 12.9 | 2wt% | 35 | 40 (melting point) | 33.2 | 12.6 | 10.5 |

Fatty acid ester nonionic surfactant (sorbitan-based)

"IONET T" products are polyhydric alcohol fatty acid ester type nonionic surfactants that uses a condensed product of sorbitan as a polyhydric alcohol component and are used as an emulsifiers, solubilizers, dispersing agents, and rust inhibitors.

"IONET T" products are ethylene oxide (EO) adducts of fatty acid esters of sorbitan, and are nonionic surfactants generally referred to as twin-type surfactants.

Fatty acid ester nonionic surfactant (sorbitan-based)

| HLB | Flow point (Fluidization point) ℃ | Surface tension *2 mN/m | Bubble test *3 mL | ||

|---|---|---|---|---|---|

| Immediately after | 5min after | ||||

| IONET T-60V | 14.9 | 24 | 36.9 | 14.2 | 13.2 |

| IONET T-80V | 15.0 | -25 ~ -23 | 39.3 | 20.5 | 17.9 |

| IONET T-20C | 16.7 | (≦0) | 38.4 | 26.3 | 22.6 |

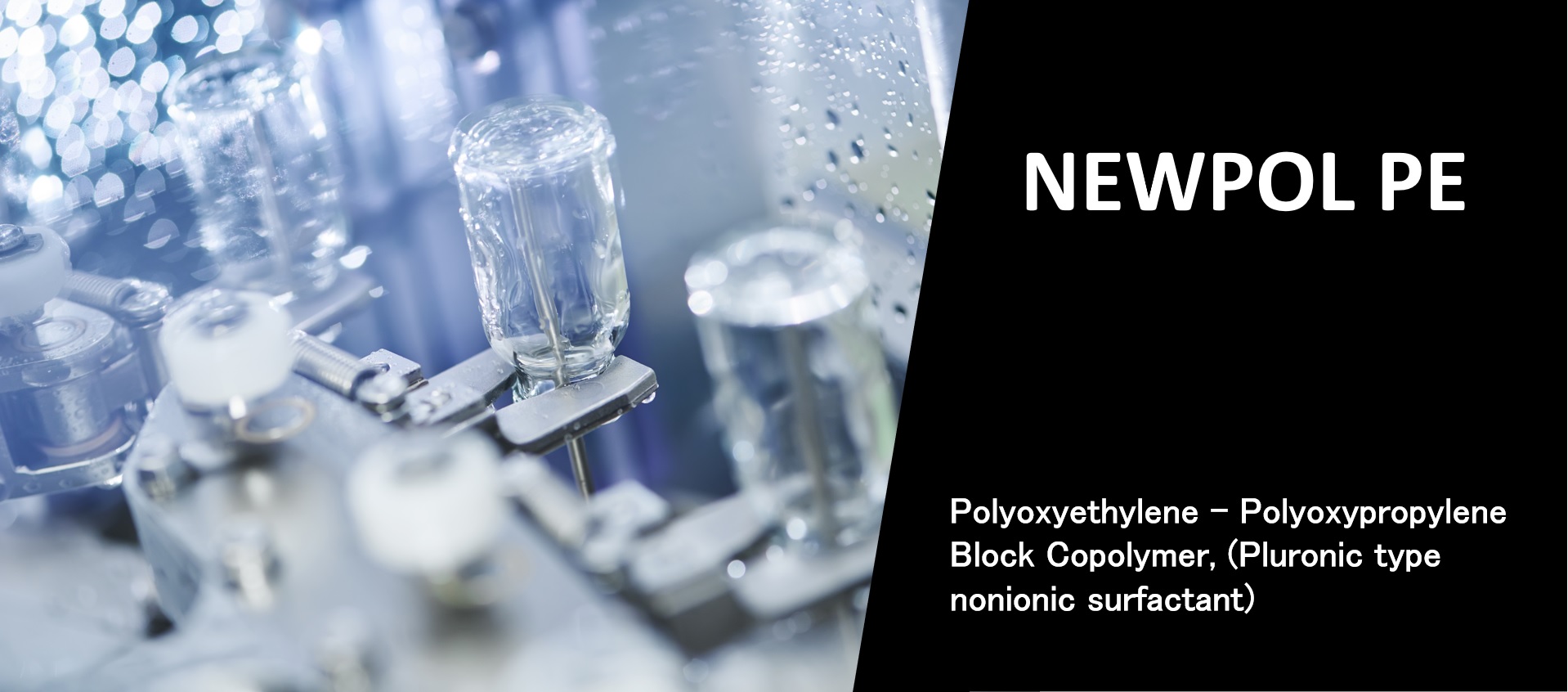

Pluronic type nonionic surfactant

"NEWPOL PE" products are block copolymers of ethylene oxide and propylene oxide, pluronic type nonionic surfactants with a polyoxypropylene chain as a hydrophobic group in the center of the molecular chain and polyoxyethylene chains as hydrophilic groups on both ends of the molecular chain.

Depending on the molecular weight of the polyoxypropylene and polyoxyethylene chains, the products are characterized by their appearance (liquid, solid, etc.), foaming and defoaming properties, cleaning power, emulsifying and dispersing power, and water dissolving speed.

Click here for the detailed page of "NEWPOL PE"

Pluronic nonionic surfactant

| Appearance *1 | Cloud point | Flow point (Fluidization point) ℃ | Surface tension *2 mN/m | Bubble test *3 mL | |||

|---|---|---|---|---|---|---|---|

| concentration | cloud point ℃ | Immediately after | 5min after | ||||

| NEWPOL PE-61 | liquid | 1wt% | 24 | (-30) | 37.6 | 9.0 | 3.7 |

| NEWPOL PE-62 | liquid | 1wt% | 30 | (≦0) | 39.0 | 18.4 | 4.2 |

| NEWPOL PE-64 | paste | 1wt% | 59 | 30 | 39.4 | 30.0 | 12.1 |

| NEWPOL PE-68 | flake | 1wt% | 113 *4 | 53 | 46.2 | 26.3 | 20.0 |

| NEWPOL PE-71 | liquid | 1wt% | 21 | (-30) | 35.7 | 2.6 | 0.0 |

| NEWPOL PE-74 | paste | 1wt% | 56 | 20~25 | 40.0 | 17.9 | 5.3 |

| NEWPOL PE-75 | paste | 1wt% | 69 | 20~25 | 39.2 | 23.7 | 10.0 |

| NEWPOL PE-78 | flake | 1wt% | 110 *4 | 54(melting point) | 44.9 | 25.8 | 20.8 |

| NEWPOL PE-108 | flake | 1wt% | 105 *4 | 57(melting point) | 43.9 | 25.0 | 17.6 |

| NEWPOL PE-128 | flake | 1wt% | 100 *4 | 62(melting point) | 41.2 | 21.8 | 18.2 |

Related products and topics

Related products

- Nonion surfactant

Low-foaming nonionic surfactant for machine and metal cleaning "SEDORAN FF"

Related topics

- What is a Surfactant?

- Sanyo Chemical's nonionic surfactant map

- Physycal properties of nonionic surfactants

- Synthetic alcohol-based nonionic surfactant (low foaming)

- Synthetic alcohol-based nonionic surfactant (primary alcohol)

- Synthetic alcohol-based nonionic surfactant (secondary alcohol)

- Natural alcohol-based nonionic surfactants (C12-C14)

- Natural alcohol-based nonionic surfactants (C16-C18)

- Natural alkylamine nonionic surfactant

- Fatty acid ester nonionic surfactant (PEG ester type)

- Fatty acid ester nonionic surfactant (sorbitan-based)

- Pluronic type nonionic surfactant

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist