Low metal corrosive cationic surfactant type antimicrobial agent"OSMORIN DA-50"

What's great about Sanyo Chemical's cationic surfactant-type antimicrobial agent "OSMOLIN DA-50"

1

Halogen-free cationic surfactant-type antimicrobial agent

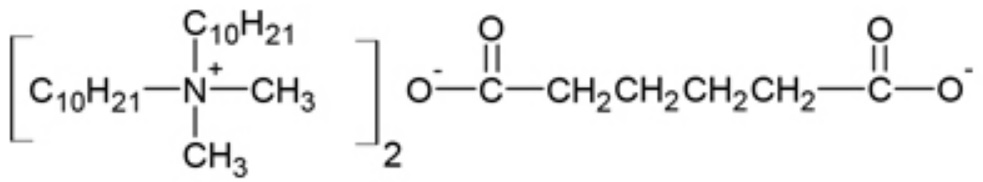

-"OSMORIN DA-50" is a halogen-free cationic surfactant antimicrobial agent in an aqueous solution containing about 48% by mass of didecyldimethylammonium adipate as the active ingredient.

-It is a halogen-free antimicrobial agent that does not generate dioxin when incinerated and has low metal corrosiveness.

-It is suitable for applications such as sterilization cleaning agents for food factories and public facilities, antimicrobial treatment of textiles, wood preservatives, and metal cleaning bath preservatives.

2

Excellent antimicrobial properties

-Exhibits a broad antimicrobial spectrum.

-Excellent mold resistance.

3

Hard water resistance

-Compared to benzalkonium chloride, it has superior resistance to hard water.

"OSMORIN DA-50" is an aqueous solution containing about 48% by mass of didecyldimethylammonium adipate as the active ingredient, and is a halogen-free cationic surfactant-type antimicrobial agent.

| Appearance | Pale yellow liquid |

|---|---|

| Active ingredient | Approx. 48% by mass |

| pH (measure of acidity) | Approx. 6 (1 mass% water dilution) |

Examples of Use

Practical examples for stand-alone applications

Antimicrobial agents for textiles

Conventional antimicrobial agents for textiles include metallic inorganic antimicrobial agents, organosilicone quaternary ammonium salts, and natural antimicrobial agents, but these have not been sufficiently effective against fungi. Moreover, quaternary ammonium salts that are effective against fungi contain halogen counter-ions, which causes the needles of textile knitting machines.

"OSMORIN DA-50" is an antimicrobial agent that shows sufficient antimicrobial effect against fungi, gram-positive, and gram-negative bacteria, and also has rust-resistant properties, making it ideal for textile applications.

Wood preservative

Quaternary ammonium salts have traditionally been used for wood preservative applications. However, conventional quaternary ammonium salts contain halogens, which can cause nails and other materials. There is also concern that dioxin may be generated when wood is incinerated. "OSMORIN DA-50" is a halogen-free preservative suitable for wood.

Practical examples of applications for blending with other drugs

Bactericidal detergent

Disinfectant cleaning agents used in food factories, food service industry, hotel kitchens, hospitals, and public facilities are required to have excellent cleaning and antibacterial power, as well as low metal corrosiveness and environmental friendliness. "OSMORIN DA-50" can be blended with a specific non-ionic surfactant to provide a germicidal cleaning agent suitable for this application. Below is an example of a formulation of a sanitizing detergent that has cleaning power and good foam rinsing.

<Example of formulation (active ingredients)

1) OSMORIN DA-50: 20% by mass

2) NEWPOL PE-61*1 : 5% by mass

3) NEWPOL PE-64*2 : 5% by mass

4) Water: Remaining amount

Total: 100% by mass

*1 Polyoxyethylene (5) polyoxypropylene glycol (30) our product

*2 Polyoxyethylene (25) polyoxypropylene glycol (30)

Metal cleaning bath preservative

Metal cleaning bath preservatives are required to have excellent rust inhibiting properties. By combining "OSMORIN DA-50" with a divalent organic acid, we can provide a metal cleaning bath preservative that has both excellent rust inhibiting and corrosion inhibiting properties.

<Formulation example (active ingredients)

(1) OSMORIN DA-50: 40% by mass

(2) Sebacic acid: 10% by mass

(3) Monoethanolamine: 7% by mass

(4) Water: Remaining amount

Total: 100% by mass

The user is responsible for determining the suitability and safety of the product for each application.

The following are examples of formulations of sanitizing detergents for use in food processing plants.

Performance data

Antimicrobial activity against bacteria and fungi

The minimum inhibitory concentration (MIC) against various bacteria and fungi and the minimum bactericidal concentration (MBC) against various bacteria of "OSMORIN DA-50" and "Cation G-50" (benzalkonium chloride solution) are shown in the table below.

Please note that these data are measured values for a single product, and values may change when other ingredients are combined.

Minimum inhibitory concentration (MIC, our measured value) against various bacteria and fungi

| MIC Mass ppm (active ingredient) | ||

|---|---|---|

| Bacterial strain | OSMORIN DA-50 | Comparison example CATION G-50 |

| Escherichia coli (E. coli) | 2.0 | 7.8 |

| Staphylococcus aureu | 0.5 | 1.0 |

| Pseudomonas aeruginosa | 15.6 | 31.3 |

| Aspergillus niger (black mold) | 32.0 | 256 |

| Penicillium citrinum (blue mold) | 7.8 | 32.0 |

The minimum growth inhibition concentration test method described in the Handbook of Bacteria and Mold Prevention (Gihoudo Shuppan Co., Ltd.) was used.

Medium: Normal bouillon liquid medium

Inoculum solution: Approximately 106 CFU/mL

Minimum Bactericidal Concentration against E. coli (MBC, our measured value)

| MBC Rating | ||||

|---|---|---|---|---|

| Bacterial strain |

Concentration of active ingredient

Mass ppm |

Contact time min |

OSMORIN DA-50 | Comparison example CATION G-50 |

| Escherichia coli | 25.0 | 1.0 | ー | + |

| 2.5 | ー | ー | ||

| 5.0 | ー | ー | ||

| 10 | ー | ー | ||

| 12.5 | 1.0 | + | + | |

| 2.5 | ー | + | ||

| 5.0 | ー | + | ||

| 10 | ー | + | ||

| 6.3 | 1.0 | + | + | |

| 2.5 | + | + | ||

| 5.0 | ー | + | ||

| 10 | ー | + | ||

Test Method

The coefficient of coalescence was measured according to the method described in the Handbook of Bacteria and Mold Prevention (Gihoudo Shuppan Co., Ltd.).

Medium : Normal bouillon liquid medium, SCDLP liquid medium

Inoculum : Approx. 106 CFU/mL

Evaluation: + indicates the bacteria are alive, - indicates the bacteria are dead.

Minimum Bactericidal Concentration against Staphylococcus aureus (MBC, our measured value)

| MBC Rating | ||||

|---|---|---|---|---|

| Bacterial strain |

Concentration of active ingredient

Mass ppm |

Contact time min |

OSMORIN DA-50 | Comparison example CATION G-50 |

| Staphylococus aureus | 25.0 | 1.0 | ー | ー |

| 2.5 | ー | ー | ||

| 5.0 | ー | ー | ||

| 10 | ー | ー | ||

| 12.5 | 1.0 | ー | + | |

| 2.5 | ー | ー | ||

| 5.0 | ー | ー | ||

| 10 | ー | ー | ||

| 6.3 | 1.0 | + | + | |

| 2.5 | + | + | ||

| 5.0 | ー | + | ||

| 10 | ー | + | ||

Test Method

The coefficient of coalescence was measured according to the method described in the Handbook of Bacteria and Mold Prevention (Gihoudo Shuppan Co., Ltd.).

Medium : Normal bouillon liquid medium, SCDLP liquid medium

Inoculum : Approx. 106 CFU/mL

Evaluation: + indicates the bacteria are alive, - indicates the bacteria are dead.

Minimum Bactericidal Concentration against Pseudomonas aeruginosa (MBC, our measured value)

| MBC Rating | ||||

|---|---|---|---|---|

| Bacterial strain |

Concentration of active ingredient

Mass ppm |

Contact time

min |

OSMORIN DA-50 | Comparison example CATION G-50 |

| Pseudomonas aeruginosa | 100 | 1.0 | ー | ー |

| 2.5 | ー | ー | ||

| 5.0 | ー | ー | ||

| 10 | ー | ー | ||

| 50 | 1.0 | ー | ー | |

| 2.5 | ー | ー | ||

| 5.0 | ー | ー | ||

| 10 | ー | ー | ||

| 25 | 1.0 | + | + | |

| 2.5 | + | + | ||

| 5.0 | ー | + | ||

| 10 | ー | + | ||

Test Method

The coefficient of coalescence was measured according to the method described in the Handbook of Bacteria and Mold Prevention (Gihoudo Shuppan Co., Ltd.).

Medium : Normal bouillon liquid medium, SCDLP liquid medium

Inoculum : Approx. 106 CFU/mL

Evaluation: + indicates the fungus is alive, - indicates the fungus is dead.

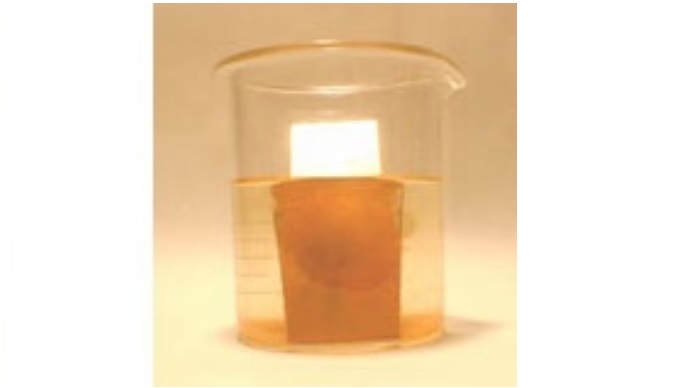

Rust Resistance

The table below shows the results of rust-preventive tests of "OSMORIN DA-50" and "Cation G-50" (benzalkonium chloride solution) on steel plates.

Results of Rust Resistance Tests on Steel Plates

| Diluted solution | Rust resistance evaluation | ||||

|---|---|---|---|---|---|

| Antibacterial agent | Diluted water | Active pharmaceutical ingredients mass% |

6 hrs. after soaking |

1 day after soaking |

2 days after soaking |

| OAMORIN DA-50 | Tap water | 1 | No rusting | No rusting | No rusting |

| 0.1 | No rusting | No rusting | No rusting | ||

| 0.01 | No rusting | Rusting | Rusting | ||

| Hard water | 1 | No rusting | No rusting | No rusting | |

| 0.1 | No rusting | Slight rusting | Rusting | ||

| 0.01 | No rusting | Rusting | Rusting | ||

| Comparison example CATION G-50 |

Tap water | 1 | Rusting | Rusting | Rusting |

| 0.1 | Rusting | Rusting | Rusting | ||

| 0.01 | Rusting | Rusting | Rusting | ||

| Hard water | 1 | Rusting | Rusting | Rusting | |

| 0.1 | Rusting | Rusting | Rusting | ||

| 0.01 | Rusting | Rusting | Rusting | ||

| (Comparison example) Tap water | Rusting | Rusting | Rusting | ||

Test Method

Steel plates were immersed in diluted solutions of "OSMORIN DA-50" and "Cation G-50" (25°C) for half a day and visually judged whether rusting had occurred or not every specified time.

Diluent: Tap water (Kyoto City), hard water (210 mass ppm calcium chloride)

Judgment

No rusting : No rusting observed

Slight rusting: Slight rusting

Rusting: Rust is present on the entire surface.

OSMORIN DA-50

(1 mass% aqueous solution of active ingredient)

(Comparison example) Tap water

Rust resistance test results (photo)

Usage

Dilute and use as is

Depending on the purpose and conditions of use, dilute the product with tap water so that the concentration of the active ingredient ranges from several mass ppm to several thousand mass ppm.

When manufacturing sanitizing detergents or other products by blending with other agents

Please check the stability and antimicrobial activity with other ingredients before use.

Precautions against misuse

"OSMORIN DA-50" is a cationic surfactant. If it is blended with soap or other anionic surfactants, precipitation may occur and the antibacterial efficacy may decrease. Avoid concomitant use with these agents.

Other precautions

When using this product in applications where it is in direct contact with the skin, check the safety (skin irritation, etc.) of the product at the concentration used in advance and use it within the range where no problems are expected.

Cautions

Before handling this product, be sure to read the "Safety Data Sheet" (SDS) for this product and its sub-materials (chemicals). The SDS can be obtained from here. https://www.sanyo-chemical.co.jp/products/en/sds/

Related Information

Related Products

-

Link to Sanyo Chemical's corporate website