Amino Acid Type Highly Functional Amphoteric Surfactant for Shampoo"PIUSERIA AMC"

What's great about amino acid type highly functional amphoteric surfactant "PIUSERIA AMC" !

1

"PIUSERIA AMC" prevents itching and dandruff when shampooing

A world first! "PIUSERIA AMC" prevents itching and dandruff by reducing the amount of surfactant residue on the skin during shampooing.

*Surveyed by Mintel, based on Mintel's database.

2

Improved thickening, foam quality, and detergency of amino acid-based shampoos

Our proprietary manufacturing technology makes it easy to create micelles with amino acid surfactants, improving thickening, foam quality, and detergency, which are issues in amino acid-based shampoos.

3

Bacteriostatic effect on dandruff-causing bacteria

"PIUSERIA AMC" has a bacteriostatic effect on dandruff-causing bacteria (Malassezia).

Ingredient Information

| Cosmetics labeling name | Sodium lauraminopropionate |

|---|---|

| Quasi-drug labeling name | Sodium beta-lauryl aminopropionate |

| Evaporation Residual | Approx. 29wt%. |

| Appearance | Pale yellow liquid |

Performance of "PIUSERIA AMC"

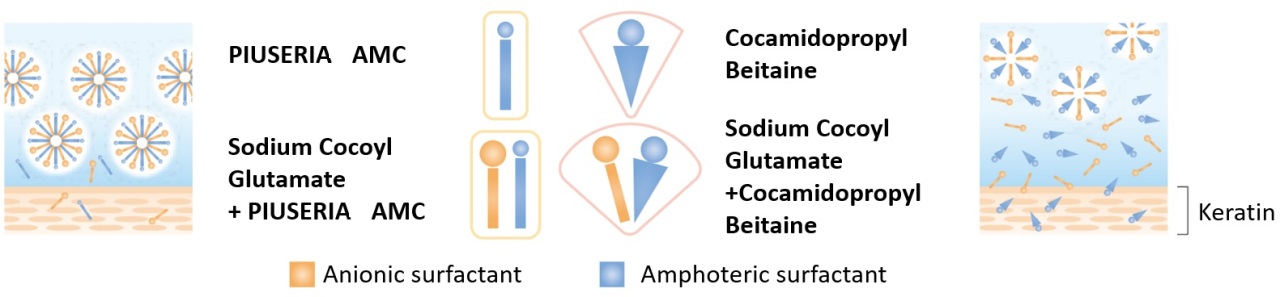

Mechanism

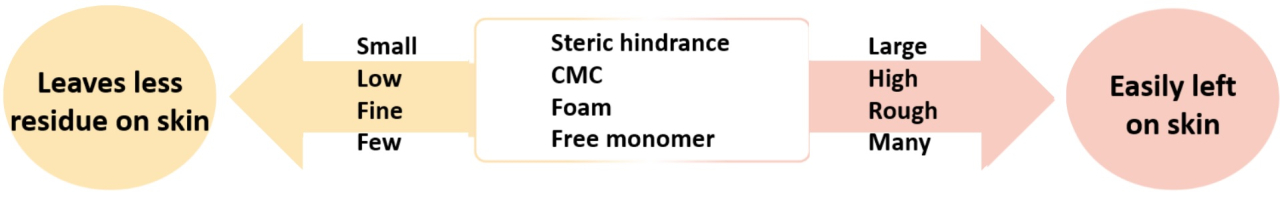

Surfactants above the critical micelle concentration (CMC) form micelles and exhibit surfactant properties such as emulsification and solubilization, so they are less likely to remain on the skin. On the other hand, below CMC, surfactants exist as monomers and are more likely to remain on the skin. The surfactant concentration in shampoo is gradually diluted from the shampoo stock solution as the shampoo is washed and rinsed, so surfactants with high CMC do not form micelles during rinsing and are more likely to remain on the skin.

Therefore, we considered the approach of reducing steric hindrance as a strategy to lower CMC. Generally, amino acid-based anionic surfactants, such as 2Na cocoyl glutamate, have a molecular structure with bulky hydrophilic groups, and cocamidopropyl betaine, a general-purpose amphoteric surfactant, also has a molecular structure with bulky hydrophilic groups, resulting in large steric hindrance in micelles when combined. In contrast, the molecular structure of PIUSERIA AMC is slim, which means that when combined with an amino acid-based anionic surfactant, the steric hindrance becomes smaller and micelles are formed more easily.

Thus, ”PIUSERIA AMC” has a low CMC due to the small steric hindrance when forming micelles with amino acid-based anionic surfactants with bulky hydrophilic groups. As a result, less monomer is left on the skin during shampoo rinsing, which reduces surfactant residue that can cause itching.

"PIUSERIA AMC" has a low steric hindrance of surfactants and can easily form micelles even at low concentrations, enabling a reduction in the amount of surfactant residue on the skin during shampooing and preventing itching and dandruff.

Performance data

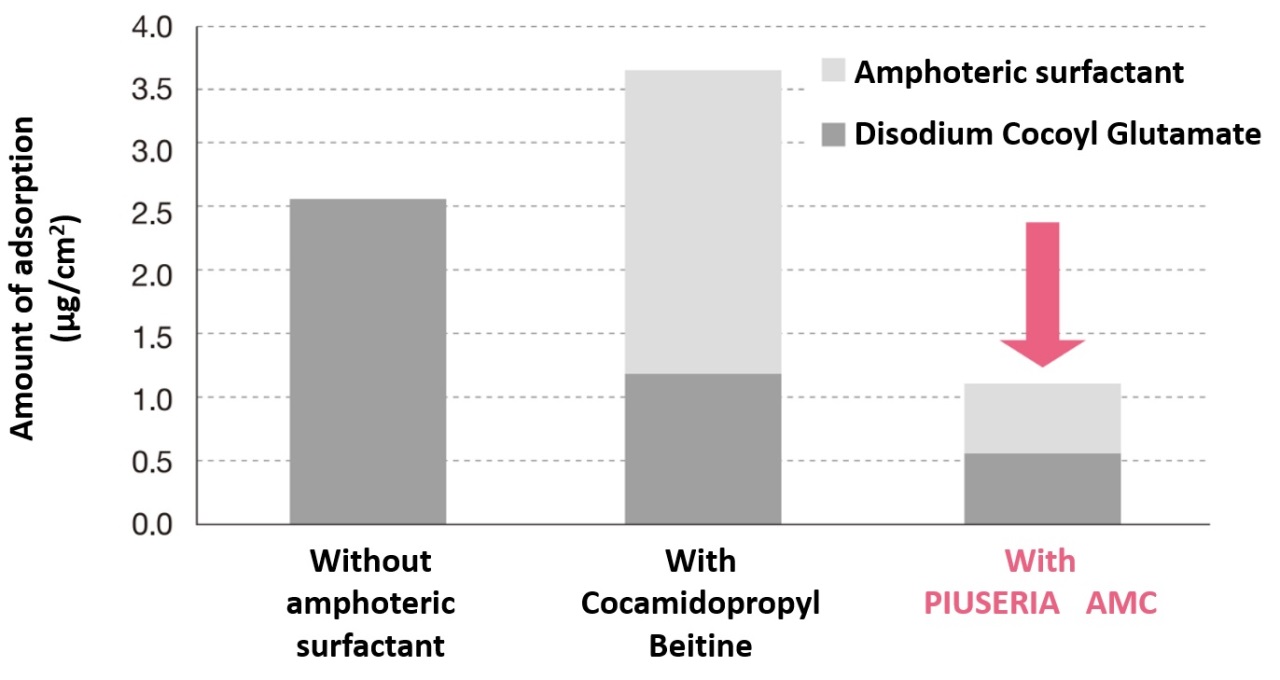

Surfactant residue on skin

"PIUSERIA AMC" can reduce the amount of surfactant remaining on the skin.

Evaluation method:

The amount of surfactant remaining on the skin was confirmed by tape stripping evaluation

Evaluation results:

It was confirmed that the amount of residual surfactant on the skin was lower when combined with PIUSERIA AMC than with cocoyl glutamate 2Na, a typical amino acid surfactant, and cocamidopropyl betaine, a general-purpose amphoteric surfactant.

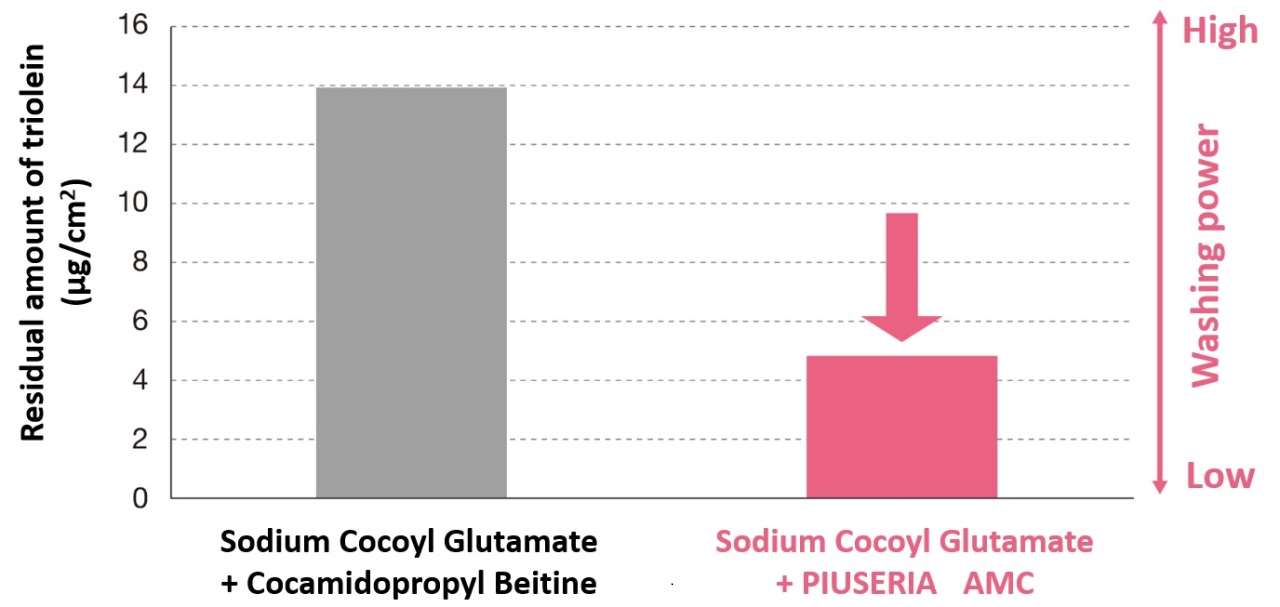

Cleansing power against sebum

"PIUSERIA" AMC improves cleaning power.

Evaluation method:

Sebum contamination remaining on the skin is confirmed by the amount of triolein remaining.

Evaluation Result:

When compared to sulfate surfactants, amino acid-based surfactants are gentle to the skin, but are considered to have weaker cleaning power. When combined with 2Na cocoyl glutamate, a typical amino acid-based surfactant, the washing power of triolein was superior to that of cocamidopropyl betaine, a general-purpose amphoteric surfactant, when combined with PIUSERIA AMC, showing superior washing power.

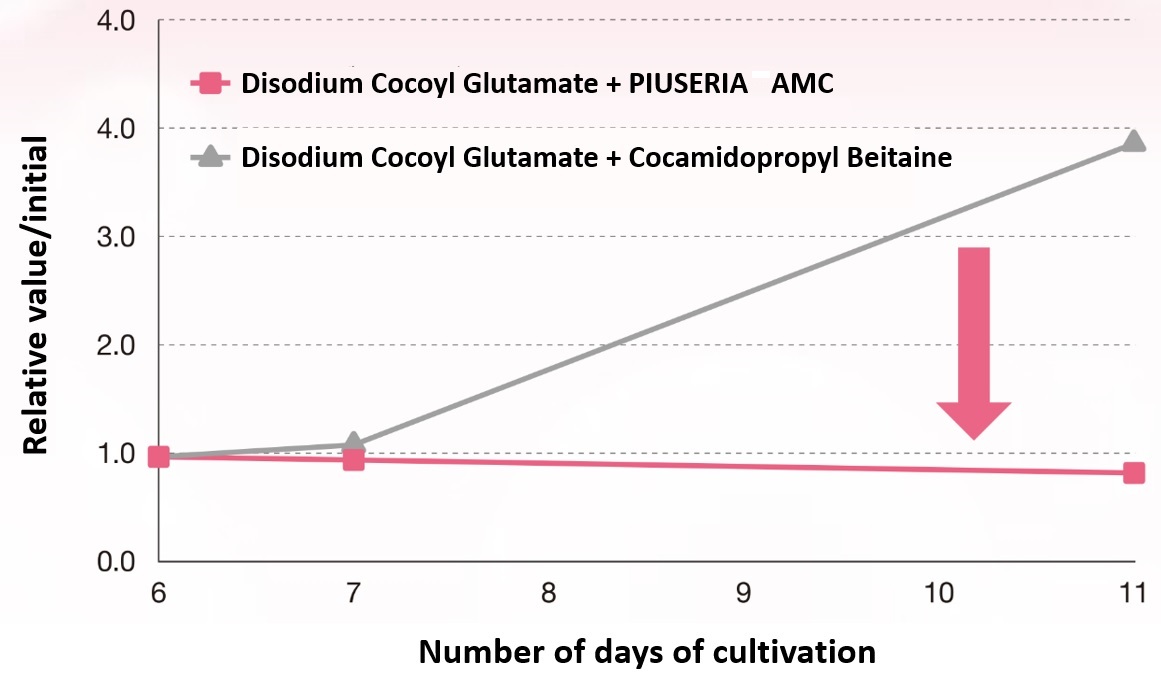

Bacteriostatic effect

Bacteriostatic effect of PIUSERIA AMC

Evaluation method:

The effect on dandruff, was verified. Evaluation of bacteriostatic effect against Malassezia, a known dandruff-causing bacterium.

Evaluation results:

When combined with a typical amino acid surfactant, sodium cocoyl glutamate 2, the growth of bacteria was inhibited until the 11th day when combined with PIUSERIA AMC, whereas when combined with cocamidopropyl betaine, a general-purpose amphoteric surfactant, no growth inhibition effect was observed. When combined with cocamidopropyl betaine, a general purpose amphoteric surfactant, no growth inhibition was observed.

The bacteriostatic properties of PIUSERIA AMC may be due to the bacteriostatic effect of the propionic acid in its skeleton.

Application data

Foamy shampoo that is gentle on hair and scalp

| Component name | Amount(wt%) | |

|---|---|---|

| A | water | 41.00 |

| Polyoctanium-22(40%aq) | 1.25 | |

| Polyoctanium-7(9%aq) | 1.00 | |

| B | EDTA-2Na | 0.05 |

| BG | 2.00 | |

| Sodium cocoyl glutamate(29%aq) | 20.70 | |

| Olefin (C14-16) sulfonic acid Na(37%aq) | 10.80 | |

| Cocamidopropyl betaine(30%aq) | 10.00 | |

| Sodium lauraminopropionate(29%aq) | 6.90 | |

| Cocamidomethyl MEA | 3.00 | |

| PEG₋160 sorbitan triisostearate | 2.00 | |

| C | PEG₋7 glyceryl palm oil fatty acid | 1.00 |

| Diisopropyl sebacate | 0.10 | |

| D | Propynyl iodidebutyl carbamate, propynyl iodide butylcarbamate, and Hydroxypropyl cyclodextrin, water (6%aq) | 0.20 |

| citric acid | q.s. | |

| Sodium hydroxide | q.s. | |

| total amount | 100 | |

<Process Example>

(1) A: After dissolving uniformly at room temperature, heat to 80°C.

(2) Heat B and C to 80°C.

(3) Add B slowly while stirring A.

(4) Add C to the mixture of A and B, and stir uniformly.

(5)Cool the mixture.

(6)Adjust pH to 6.0±0.1.

(7)After stirring uniformly, deaerate.

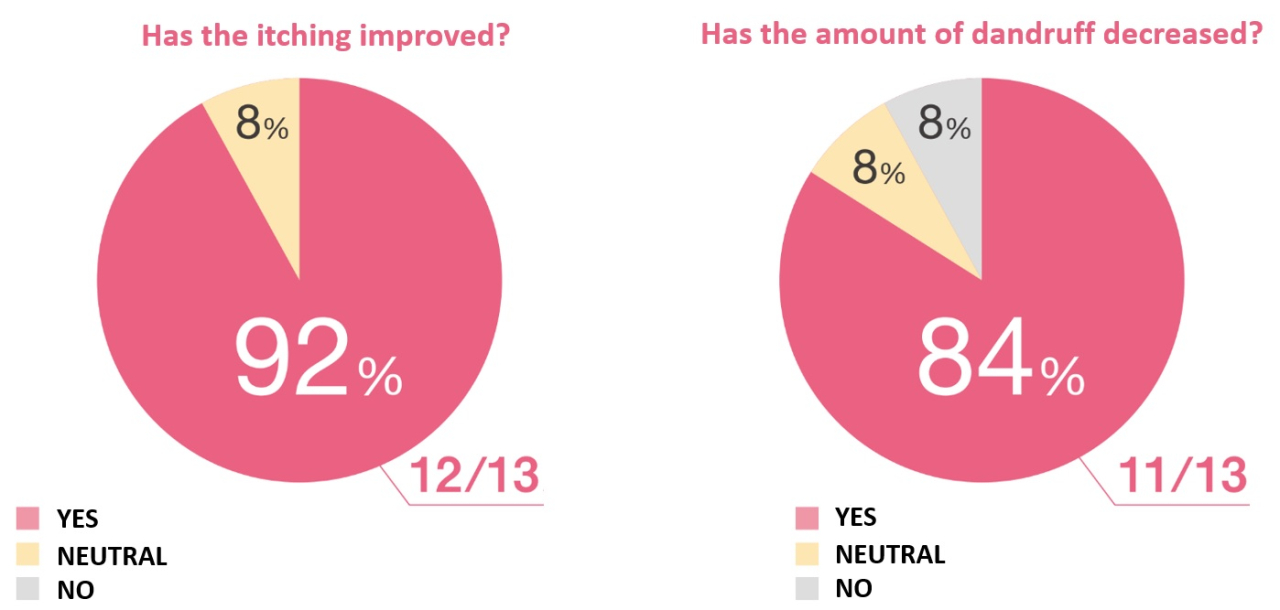

Reduction of itchiness Monitor test results

Excerpts from the questionnaire results of the monitoring study

- It felt gentle on the skin.

- Definitely improved itching.

- Scalp does not dry out

- It had a good lather and washed well.

- My hair is now silky smooth.

- Hair has more body and volume

Conducted by SOUKEN Co.

The subjects used the product for 2 weeks and were asked about the condition of their hair before and after use in the form of a questionnaire.

Subjects

Thirteen Japanese men and women between the ages of 20 and 60 who were concerned about dandruff and itchiness on their scalp.

Related Information

Related Products

| Cosmetic raw materials |

|---|

| Links to Sanyo Chemical's corporate site |

|---|

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist