Urethane Pressure Sensitive Adhesives (PSA)"POLYTHICK UP"

Our Proprietary Special Polyols Solve the Drawbacks of Conventional Urethane Pressure Sensitive Adhesives (PSA).

Stable Adhesive Properties Independent of Temperature and Peeling Speed Actualizes Oil and Abrasion Resistance Unique to Urethane.

Sanyo Chemical's Polyurethane Pressure Sensitive Adhesive "POLYTHICK UP" Products are here!

1

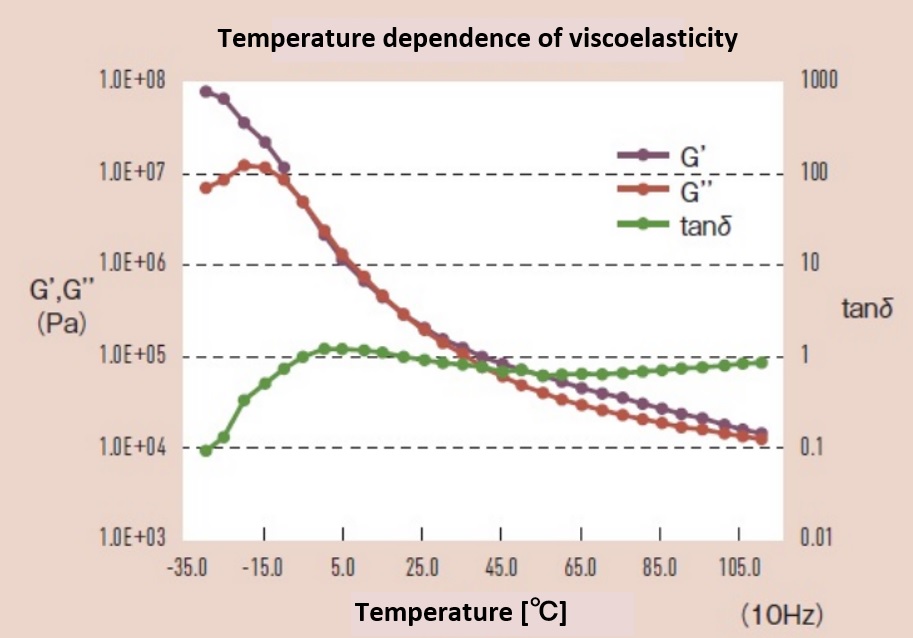

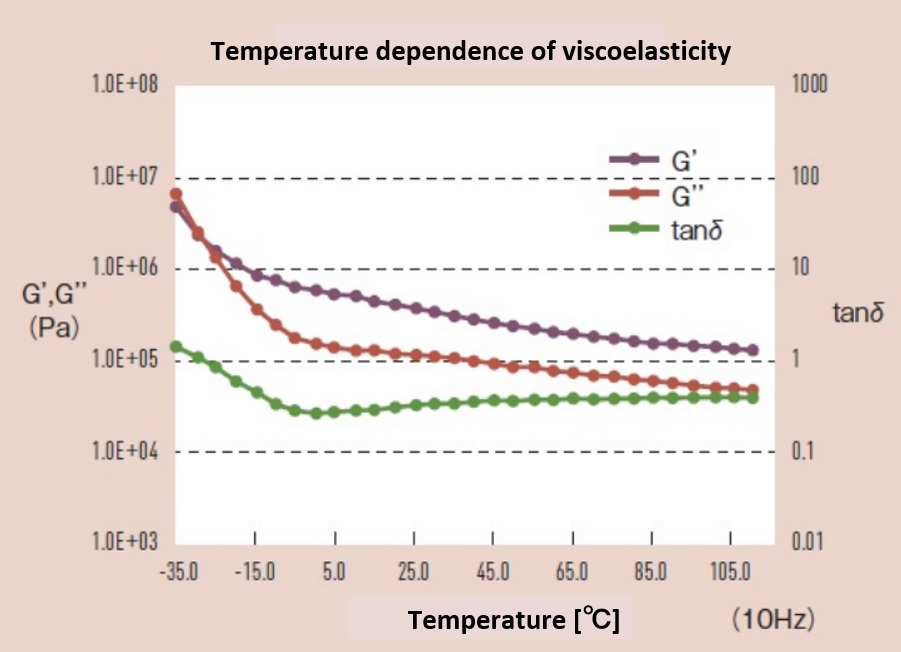

Stable Adhesive Properties Independent of Temperature and Peeling Speed

2

"POLYTHICK UP" Has Oil and Abrasion Resistance Unique to Urethane

3

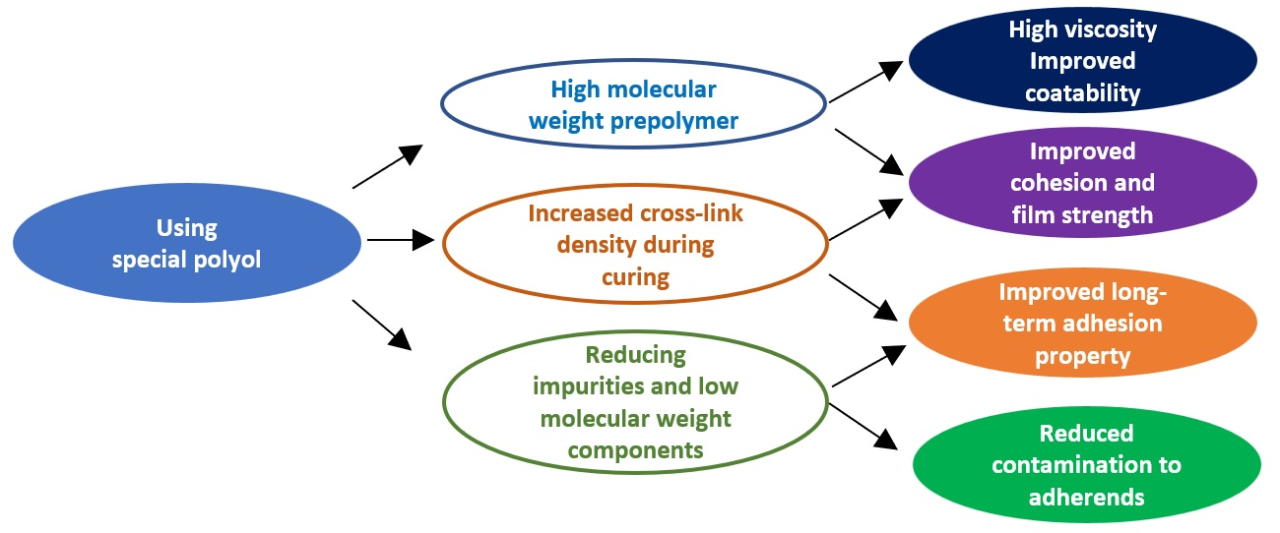

Solves the Weak Points of Conventional Urethane Adhesives with our Proprietary Special Polyols

- High viscosity from high molecular weight of the prepolymer

- Improved cohesion and film strength due to increased cross-link density during curing

- Improvement of long-term adhesion properties by reducing impurities and low molecular weight components

Potential and Challenges of Urethane Pressure Sensitive Adhesives

In urethane adhesives, a solution of polyol (OH) as the main agent, poly isocyanate (NCO) as the curing agent, and additives is coated on a substrate such as film and heated to cross-link and cure to form the adhesive layer.

Advantages of Urethane Pressure Sensitive Adhesives

- In addition to low dependence on time, temperature, peeling speed, etc., it has excellent oil resistance and abrasion resistance unique to urethane.

- Since it consists of two components, the main agent and hardener, it is easy to control physical properties such as reactivity, hardness, and elastic modulus, and it is expected to be applied to a wide range of applications.

Comparison of Acrylic and Urethane Pressure Sensitive Adhesives

| Acrylic Pressure Sensitive Adhesive | Urethane Pressure Sensitive Adhesive |

|---|---|

<Features>

|

<Features>

|

|

|

| Low modulus of elasticity above room temperature and high tanδ ⇒High tackiness and instantaneous adhesion |

Small temperature dependence of viscoelasticity curve ⇒Little temperature dependence of adhesive strength |

Problems with Conventional Urethane Pressure Sensitive Adhesives

Conventional urethane adhesives have the following issues, which have limited their applications.

- Adhesive strength is difficult to adjust due to the high cohesive strength of the urethane group.

- When the cohesive strength or cross-link density of hard segments is reduced to improve adhesion, the strength of the adhesive layer decreases, leading to glue residue.

- Difficult to adjust to appropriate viscosity due to difficulty in achieving high molecular weight

Sanyo Chemical's Urethane Pressure Sensitive Adhesives

Features of "POLYTHICK UP"

Sanyo Chemical's "POLYTHICK UP" products of urethane adhesives solves the problems of conventional urethane adhesives by introducing special polyols.

- High viscosity from high molecular weight of the prepolymer

- Improved cohesion and film strength due to increased cross-link density during curing

- Improved long-term adhesion properties due to reduced impurities and low molecular weight components

Application Examples and Features to be Utilized

Slight to Weak Adhesion Range

Protective film for electronic components and optical films

- Stable adhesive properties

- Removability

- Low Contamination

- Urethane film strength

- Antistatic properties

Lamination and masking of automotive and construction components

- Stable adhesive properties

- Durability

- Weather resistance

Medium to Strong Adhesion Range

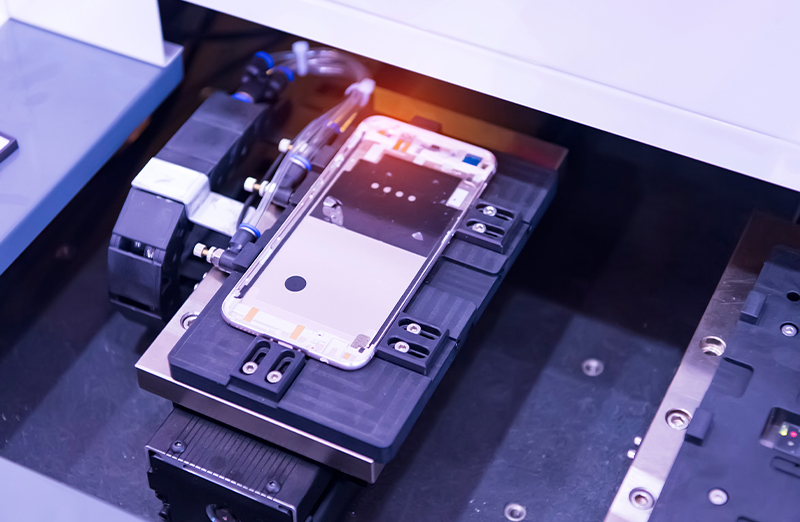

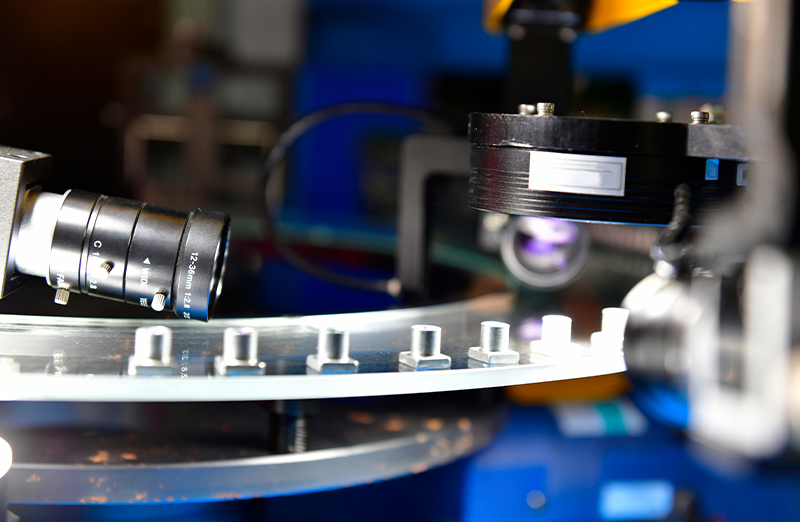

Lamination of touch panels and display components

- Stable adhesive properties

- Low contamination

- Small temperature dependence

Holding electric/electronic components and optical components during transport to the next process

- Stable adhesive properties

- Low contamination

- Small temperature dependence

Adhesive tape for fixing medical tubes and catheters,

film dressing materials for medical use,

surgical tapes, wearable applications, etc.

- Low odor and skin irritation

- Comfortable due to high moisture permeability

Main Lineup of the "POLYTHICK UP" Products

| POLYTHICK UP products (Developmental product) | ||||||

|---|---|---|---|---|---|---|

| Type | Slight adhesion type (Solvent-based) |

Slight adhesion type (Solvent-based) |

Medium adhesion type (Solvent-free) |

Strong adhesion type (Solvent-based) |

||

| Base | POLYTHICK UPW-1 (OH-terminated prepolymer) |

POLYTHICK UPW-2 (OH-terminated prepolymer) |

POLYTHICK UPS-1A (OH-terminated prepolymer) |

POLYTHICK UPK-2 (OH-terminated prepolymer) |

||

| Hardener | Polyfunctional isocyanate | Polyfunctional isocyanate |

POLYTHICK UPS-1B |

Polyfunctional isocyanate | ||

| Base/hardener (by weight) |

98/2 | 94/6 | 60/40 | 99.5/0.5 | ||

| Base property | Appearance | Colorless to pale yellow liquid | ||||

| Viscosity at 25°C (mPa・s) | 10000 | 8000 | 20000 | 5000 | ||

| Evaporated residue | 50 (ethyl acetate) | 40 (ethyl acetate) | 100 | 30 (ethyl acetate/THF) |

||

| Molecular weight Mw | 60000 | 200000 | 20000 | 200000‐300000 | ||

| Cured properties | Adhesion strength | 0.04 (Toward glass, Adhesive film thickness: 30 μm) |

0.02 (Toward glass, Adhesive film thickness: 30 μm) |

12 (Toward SUS, Adhesive film thickness: 30 μm) |

21 (Toward SUS, Adhesive film thickness: 30 μm) |

|

| Retention strength (mm/24h) | 0.0 | 0.0 | 0.0 | 0.0 | ||

| Tg(℃) | <-20℃ | <-20℃ | <-35 ℃ | <-45 ℃ | ||

| Surface resistivity (Ω/□) | 108 (With antistatic agent) 1012 (Without antistatic agent) |

|||||

| Humidity permeability (A-1 method) (g/m2/day) | 3000 (30μm) | |||||

| Transparency (Haze) | 0.3 (30μm) | 0.3 (30μm) | 0.3 (30μm) | 0.4 (30μm) | ||

| Refractive index | 1.47 | 1.47 | 1.46 | 1.47 | ||

| Advantages | Special polyethers are used to achieve high molecular weight.

|

High molecular weight by using special polyols

|

||||

Related Information

Related Products

Technology and Application Topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist