High-performance Polyurethane(PU) Tooling Boards"SANMODUR"

High-performance Polyurethane(PU) tooling boards for product design, prototyping, and production processes

What's Great about Sanyo Chemical's Polyurethane(PU) Tooling Boards "SANMODUR"

"SANMODUR" is a high-performance polyurethane(PU) tooling board for making various models and molds produced during the product development process (design, prototyping, and low-volume production).

1

High-performance tooling board with excellent density, uniformity, and machinability

The mechanical floss method makes it possible to produce high-performance tooling board with fine, uniform air bubbles.

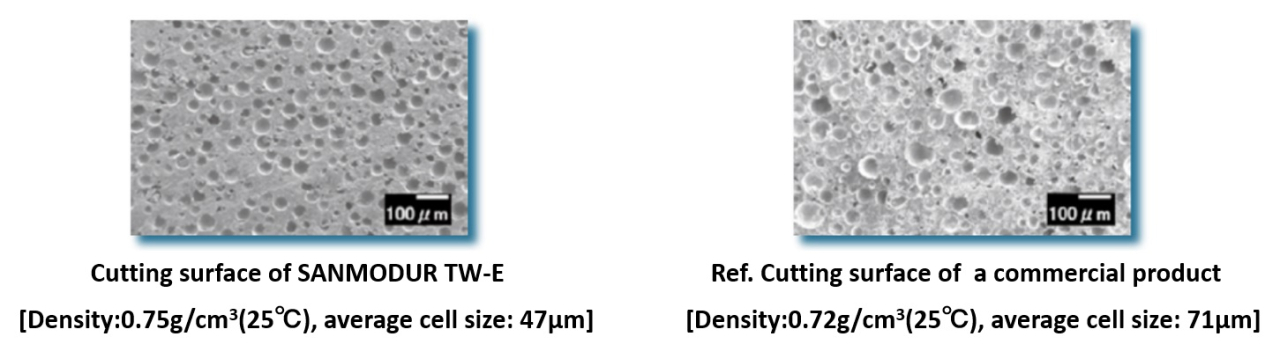

As the electron micrograph below shows, SANMODUR TW-E has a very fine texture, resulting in a clean cutting surface.

2

Antistatic grade lineup

We also have a lineup of types with antistatic properties that prevents dust generating from the cutting process from adhering to NC machine tools and operators. (SANMODUR MH-E, MS-E, 7K-E, TW-E )

3

Lineup of varieties and sizes with performance for each application

- Each SANMODUR product type is designed to meet the specific needs of each application, including lightness, strength, heat resistance, dimensional stability, and low dispersal of cutting dust.

- Various sizes are available for each SANMODUR type to reduce material loss and gluing work.

High Performance Polyurethane(PU) Tooling Board "SANMODUR" Application Examples

“SANMODUR” is a polyurethane(PU) tooling board used in each process of product development.

Tire mold model using "SANMODUR"

Tire mold model using "SANMODUR"

[Photo courtesy of NGK FINE MOLD Co.]

Inspection jig with "SANMODUR"

[Photo courtesy of Technical Model Co.]

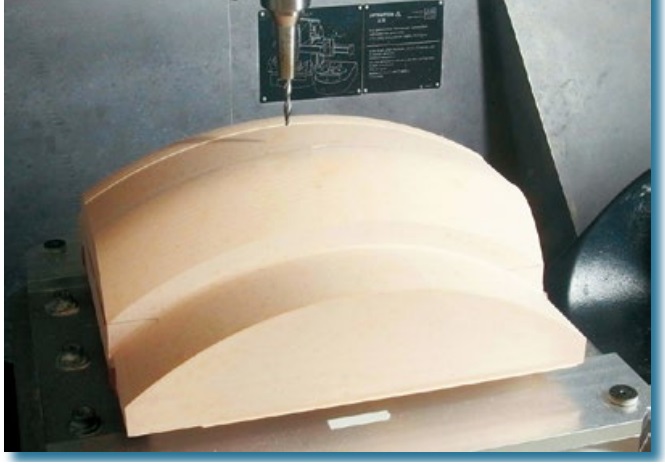

Precision machining model using "SANMODUR TW-E"

Precision machining model using "SANMODUR TW-E"

[Photo courtesy of Technical Model Co.]

Image of design model (concept car)

We have a lineup of polyurethane(PU) tooling board varieties that can be adapted to each process of product development design, prototyping, and mass production.

1

Planning

Developing concepts and CAD designs.

2

Design

Types of models/molds: Design models (mock-up models, styling models, throw-away models)

Properties required of tooling board:

lightness, fineness of texture, good hand and machine machinability

Applicable SANMODUR Grades

- MH-E (Lightweight grade with antistatic properties. (Fine texture for low density, enabling simplification of the coating process)

- LC-M (Lightweight grade with excellent dimensional stability, heat resistance, and workability)

- MS-E (Fine texture, strength and dimensional stability. Antistatic properties. Good processability)

- MDX-M (Fine texture and excellent machinability, enabling creation of beautiful models with smooth surfaces)

3

Prototype

Type of model/mold: Master model (casting model, vacuum-formed mold)

Properties required for tooling board: Denseness, precision, strength, good mechanical machinability

Applicable SANMODUR Grades

- NO7K-E (General-purpose grade. Antistatic. Well-balanced performance)

- TW-E (General-purpose grade with antistatic properties, dense and high strength among general-purpose grades, good dimensional stability)

- VM (High density and very dense. Suitable for vacuum molding dies that require transparency.)

- NV (Good hand workability and machinability for high density.)

4

Mass production

Types of models/molds: Inspection jigs, heat-resistant molding molds

Characteristics required for tooling board: High precision, high strength, high hardness, high heat resistance

Applicable SANMODUR grades

- TW-E (general-purpose grade. Antistatic. Dense and high strength among general-purpose grades. Good dimensional stability)

- NZ-M (Particularly high precision and heat resistance, excellent dimensional stability)

- HD-M (High hardness and high density. HD-M (high hardness and dense, excellent in bending strength and impact strength)

- NV (Good workability and machinability in even with high density)

Why is "SANMODUR" Suitable for Model and Prototype Molds?

About polyurethane(PU) tooling board

Tooling board is widely used for prototype models of automobile engines and parts because it is easier to cut than wood and has superior dimensional stability and strength. Among these, polyurethane tooling board, which is easy to process and offers a high degree of design freedom, has become the mainstream for models and prototype molds.

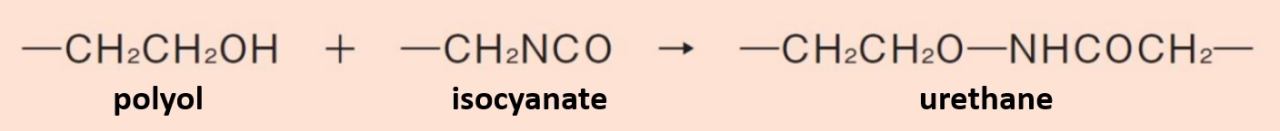

Polyurethane is produced by the reaction of polyols and isocyanates. When a small amount of water is added, the reaction between the water and isocyanate produces carbon dioxide gas, and by adjusting the amount of bubbles produced by this carbon dioxide gas, a polyurethane foam of the desired density is produced. The "water foaming method" is known as a common method for manufacturing rigid polyurethane foam.

Reaction1: Urethanation reaction

Reaction2: Carbon dioxide generation in the presence of water

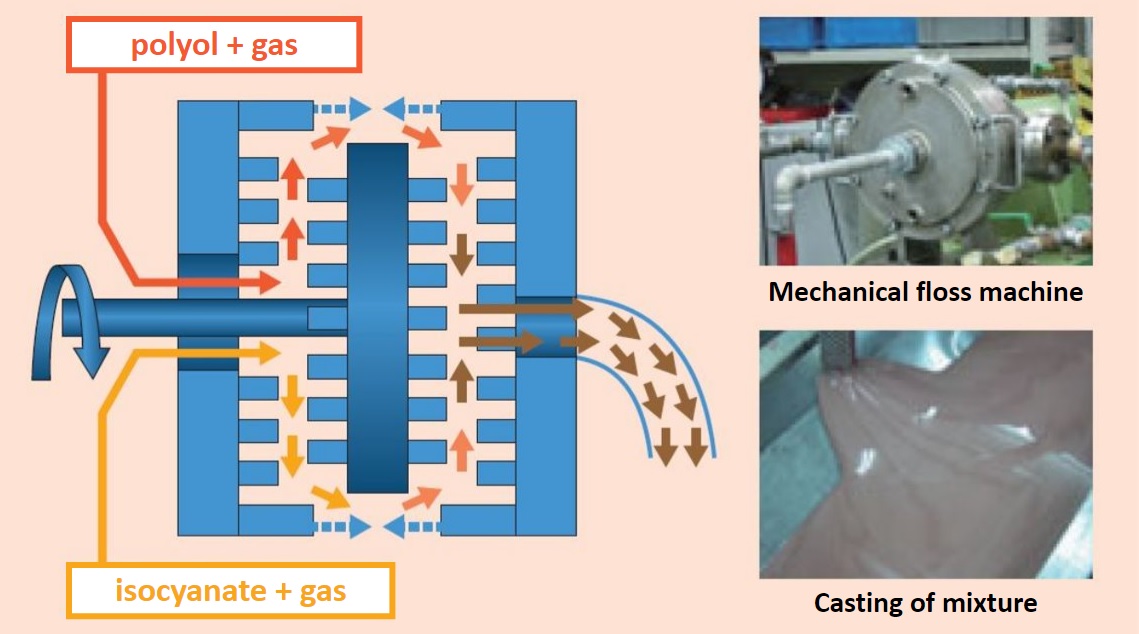

"SANMODUR" Original Production Method No.1 : Mechanical Floss Method

Our "SANMODUR" is a high-performance polyurethane(PU) tooling board that employs a foaming method called the mechanical floss method. In this method, when liquid polyol and isocyanate components are mixed, inert gas such as nitrogen is blown in and stirred vigorously to forcibly create fine, uniform cells in the mixed liquid. The mixed liquid hardens through a urethane reaction and becomes a polyurethane resin with microbubbles ranging from several μm to several tens of μm. The density can be finely controlled by the amount of gas injected, which is the reason why the physical properties of "SANMODUR" differ greatly from those of other tooling boards.

Although polyols, isocyanates, and fillers have different characteristics, density is the most important factor that determines the physical properties of synthetic wood. "SANMODUR" has uniform and fine cells and is available in densities from a minimum of 0.35 g/cm3 to a maximum of 1.13 g/cm3.

"SANMODUR" Original Production Method No.2: Continuous Casting Method

The mold is poured into a general tooling board mold and each piece is molded in a single batch. One of the concerns with this method is that the density and other physical properties tend to be non-uniform depending on the location in the mold and the batch.

In contrast, "SANMODUR" employs the continuous casting method as a unique manufacturing method to achieve a homogeneous structure. In this method, the mixed components mixed by the mechanical floss method are poured, cured, and cut in a continuous process, which enables a large number of sheets to be produced per batch and stable quality.

Conceptual diagram of the "SANMODUR" continuous casting method

"SANMODUR" is a high-functional (fine and uniform) tooling board by our original manufacturing method [mechanical floss method + continuous casting method].

Typical Features of the High-performance Polyurethane Tooling Board "SANMODUR"

The high-performance tooling boards "SANMODUR" are designed with polyurethane compositions and our proprietary manufacturing methods (mechanical floss method and continuous casting method) to provide a lineup of easy-to-use functions as tooling materials for various applications. Below is a list of representative functions.

1

Machinability (density)

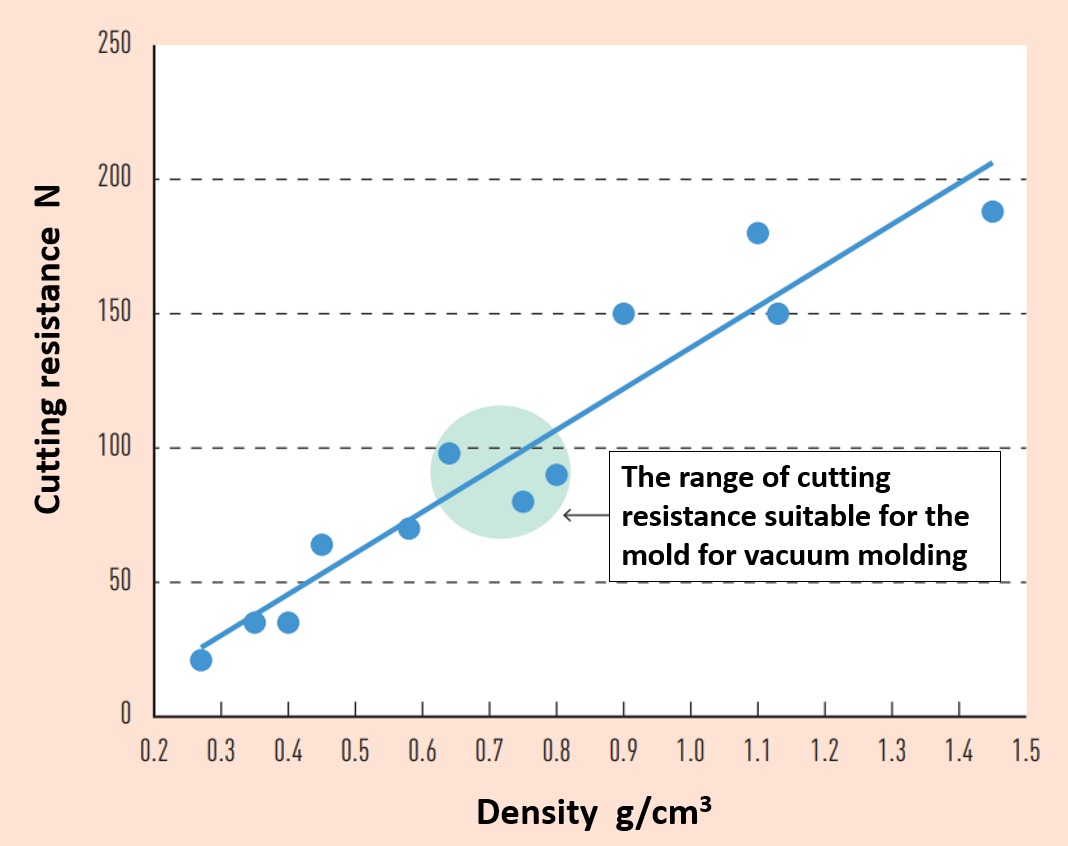

Fig. Density and cutting resistance of "SANMODUR"

The cutting ability of "SANMODUR" correlates with its density. Select the optimum part number based on the balance between the desired cutting speed and other physical properties.

2

Fineness (surface roughness)

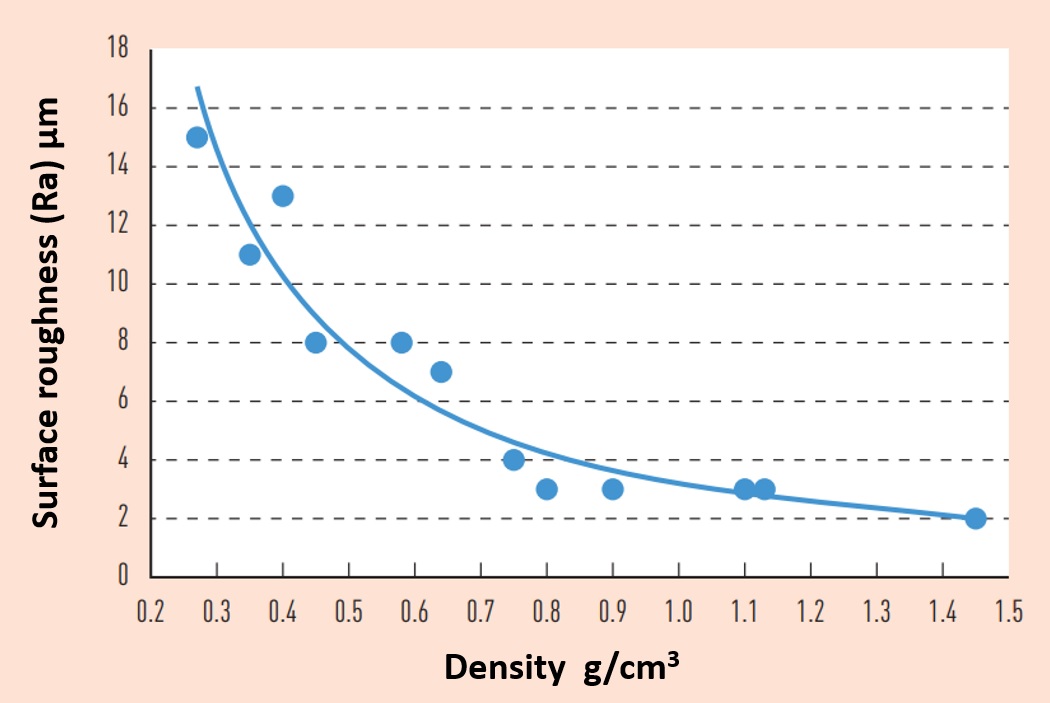

Fig. "SANMODUR" density and surface roughness (Ra)

By adopting the mechanical floss method and optimizing the polyurethane composition design, the surface roughness Ra is smaller than that of other companies' tooling boards, contributing to shortening the time required for sandpapering and surface preparation before painting.

3

Heat resistance and strength

Fig. Density and heat deformation temperature of "SANMODUR"

In vacuum molding using "SANMODUR" as a resin mold, it is necessary to select a lineup with heat resistance and strength to withstand the molding conditions because the surface is heated for several seconds by the heat from the resin to be molded, even for a few prototypes, and the mold is subject to compressive forces.

4

Antistatic properties

Fig. Change in the amount of static charge of facets of SANMODUR TW-E and TW

"SANMODUR TW-E" is a grade with antistatic properties while maintaining the mechanical properties of "SANMODUR TW".

Chips generated during cutting of "SANMODUR" do not persistently adhere to the machine tool or operator, making the work environment cleaner and preventing static electricity problems.

5

Dimensional stability

- Molds must not change dimension significantly during temperature change or vacuum forming

- Fillers are added to SANMODUR to improve dimensional stability.

- The mechanical floss method ensures uniform dispersion of air bubbles in the tooling board, which tends to reduce the coefficient of linear expansion equally across the board.

6

Blade wear

"SANMODUR TW-E" is designed to reduce the burden on drill blades and generation of frictional heat by using a slippery material for the inorganic filler.

Main lineup of high-performance tooling board "SANMODUR"

List of applications and features of the main lineup

| Product name | Use | Features | Density(25℃) g/cm3 JIS K7222 |

Hardness Shore D ASTM D2240 |

|---|---|---|---|---|

| SANMODUR MH-E |

|

|

0.35 | 43 |

| SANMODUR LC-M |

|

|

0.40 | 40 |

| SANMODUR MS-E |

|

|

0.45 | 52 |

| SANMODUR MDX-M |

|

|

0.58 | 54 |

| SANMODUR NO7-K |

|

|

0.64 | 61 |

| SANMODUR TW-E |

|

|

0.75 | 64 |

| SANMODUR VM |

|

|

0.80 | 64 |

| SANMODUR NZ-M |

|

|

0.90 | 80 |

| SANMODUR HD-M |

|

|

1.10 | 81 |

| SANMODUR NV |

|

|

1.13 | 74 |

Physical properties of the main lineup of "SANMODUR" (1)

| Product name | Bending strength MPa |

Impact strength kJ/m2 |

Coefficient of linear expansion ℃-1 |

Heat deformation temp. ℃ |

|---|---|---|---|---|

| JIS K6911 |

JIS K6911 |

JIS K7222 | JIS K6911 | |

| SANMODUR MH-E | 7.4 | 2.4 | 54×10-6 | 54 |

| SANMODUR LC-M | 10.0 | 1.9 | 47×10-6 | 80 |

| SANMODUR MS-E | 13.6 | 4.3 | 58×10-6 | 65 |

| SANMODUR MDX-M | 17.0 | 5.0 | 50×10-6 | 85 |

| SANMODUR NO7-K | 26.5 | 7.5 | 60×10-6 | 90 |

| SANMODUR TW-E | 25.0 | 5.7 | 47×10-6 | 95 |

| SANMODUR VM | 25.0 | 6.0 | 50×10-6 | 85 |

| SANMODUR NZ-M | 46.0 | 5.5 | 29×10-6 | 140 |

| SANMODUR HD-M | 58.0 | 11.0 | 53×10-6 | 100 |

| SANMODUR NV | 32.0 | 8.0 | 52×10-6 | 93 |

Physical properties of the main lineup of "SANMODUR" (2)

| Product name | Surface roughness(Ra) μm |

Cutting Resistance N |

Blade wear ㎜ |

|---|---|---|---|

| Our test method*1 | Our test method*2 | Our test method*3 | |

| SANMODUR MH-E | 11 | 35 | 0.9 |

| SANMODUR LC-M | 13 | 35 | 0.9 |

| SANMODUR MS-E | 8 | 64 | 0.9 |

| SANMODUR MDX-M | 8 | 70 | 1.0 |

| SANMODUR NO7-K | 7 | 98 | 0.7 |

| SANMODUR TW-E | 4 | 80 | 1.0 |

| SANMODUR VM | 3 | 90 | 1.0 |

| SANMODUR NZ-M | 3 | 150 | 4.5 |

| SANMODUR HD-M | 3 | 169 | 1.5 |

| SANMODUR NV | 3 | 150 | 0.8 |

*1 Measured with a non-contact 3D surface roughness meter manufactured by Keyence Corporation on the cut surface of a tooling board sample cut with an NC machine tool manufactured by Iwama Kogyosho Corporation.

(The absolute value of the unevenness of the sample surface is averaged.)

*2 Four-component dynamometer was used to measure resistance during tooling board cutting on an NC machine tool (16 mm diameter carbide throw-away insert, 5,000 rpm, feed rate 2,000 mm/min) at a depth of cut of 3 mm. Resistance was measured while tooling board at a depth of cut of 3 mm.

*3 After 10 m of continuous cutting of tooling board at a depth of cut of 3 mm on a NC machine tool (10 mm diameter HSS straight edge, 10,000 rpm rotation speed, 100 mm/min feed rate, 1 mm travel) .

After continuous cutting of tooling board with a depth of cut of 3 mm, the wear of the cutting edge was measured under a stereo microscope (×50).

Recommended adhesives for high-performance polyurethane tooling board "SANMODUR"

SANMODUR MH-E, LC-M

Cyanon D-60 manufactured by Koatsu Gas Industry Co.,Ltd.

Pegaloc NC-700 manufactured by Koatsu Gas Industry Co.,Ltd.

SANMODUR MS-E、MDX-M、NO7K-E、TW-E、VM

SANMODUR AD-221 Manufactured by Sanyo Chemical Industries, Ltd.

Cyanon D-60 manufactured by Koatsu Gas Industry Co.

Pegaloc NC-501 by Koatsu Gas Industry Co.,Ltd.

SANMODUR NZ-M, HD-M, NV

Cyanon D-60 manufactured by Koatsu Gas Industry Co.,Ltd.

Pegarock NC-501 manufactured by Koatsu Gas Industry Co.,Ltd.

Size and packing

The table below shows the size and packing for each grade of "SANMODUR".

| Product name | Size ㎜ | Packing |

|---|---|---|

| SANMODUR MH-5E | 1500×500× 50 | 2pcs/box |

| SANMODUR MH-10E | 1500×500×100 | 1pce/box |

| SANMODUR MH-15E | 1500×500×150 | 1pce/box |

| SANMODUR LC-5M | 1500×500× 50 | 2pcs/box |

| SANMODUR LC-10M | 1500×500×100 | 1pce/box |

| SANMODUR LC-15M | 1500×500×150 | 1pce/box |

| SANMODUR LC-20M | 1500×500×200 | 1pce/box |

| SANMODUR MS-3E | 1500×500× 30 | 2pcs/box |

| SANMODUR MS-5E | 1500×500× 50 | 2pcs/box |

| SANMODUR MS-8E | 1500×500× 80 | 1pce/box |

| SANMODUR MS-10E | 1500×500×100 | 1pce/box |

| SANMODUR MDX-25M | 1500×500× 25 | 4pcs/box |

| SANMODUR MDX-5M | 1500×500× 50 | 2pcs/box |

| SANMODUR MDX-10M | 1500×500×100 | 1pce/box |

| SANMODUR MDX-15M | 1500×500×150 | 1pce/box |

| SANMODUR NO7K-2E | 1000×500× 20 | 4pcs/box |

| SANMODUR NO7K-3E | 1000×500× 30 | 2pcs/box |

| SANMODUR NO7K-5E | 1500×500× 50 | 2pcs/box |

| SANMODUR NO7K-10E | 1500×500×100 | 1pce/box |

| SANMODUR TW-3E | 1500×500× 30 | 2pcs/box |

| SANMODUR TW-5E | 1500×500× 50 | 2pcs/box |

| SANMODUR TW-8E | 1500×500× 80 | 1pce/box |

| SANMODUR TW-10E | 1500×500×100 | 1pce/box |

| SANMODUR TW-15E | 1000×500×150 | 1pce/box |

| SANMODUR VM-1505F | 1500×500× 50 | 1pce/box |

| SANMODUR VM-8 | 1500×500× 80 | 1pce/box |

| SANMODUR NZ-3M | 1000×500× 30 | 2pcs/box |

| SANMODUR NZ-5M | 1000×500× 50 | 1pce/box |

| SANMODUR HD-3M | 1000×500× 30 | 2pcs/box |

| SANMODUR HD-5M | 1000×500× 50 | 1pce/box |

| SANMODUR NV-1003 | 1000×500× 30 | 2pcs/box |

| SANMODUR NV-1005 | 1000×500× 50 | 1pce/box |

| SANMODUR NV-1010 | 1000×500×100 | 1pce/box |

Example of Model Manufacturing Process Using High Performance Tooling Board " "SANMODUR"

1

Cutting

Cut the tooling board into rough model shapes using a band saw or similar tool.

2

Lamination

To obtain a model of a given thickness, several SANMODUR are laminated together with adhesive, if necessary.

3

Machining

Tooling board is cut using NC machine tools under different conditions in the order of rough machining, medium machining, and finishing.

4

Final processing

After cutting, the tooling board is finished using a file, sandpaper, etc., as necessary.

5

Painting (⇒completion)

Paint finish will be applied as needed.

Example of cutting conditions for high-performance tooling board on a woodworking NC machine tool

(1) Example of cutting conditions when using a high-speed steel ball end mill

Product Name:

SANMODUR MH-E, LC-M

Cutter Name:

High speed steel ball end mill

| Adhesive processing | Cutter diameter :20㎜ Cutter speed :12000rpm Feed speed :6000㎜/min Amount of movement(pick) :15㎜ Depth of cut :10㎜ |

|---|---|

| Processing | Cutter diameter :20㎜ Cutter speed :8000rpm Feed speed :4000㎜/min Amount of movement(pick) :5㎜ Depth of cut :5㎜ |

| Finishing touches | Cutter diameter :10㎜ Cutter speed :6000rpm Feed speed :3000㎜/min Amount of movement(pick) :0.8㎜ Depth of cut :0.5㎜ |

Product Name:

SANMODUR MS-E

Cutter name:

High speed steel ball end mill

| Adhesive processing | Cutter diameter :20㎜ Cutter speed :15000rpm Feed speed :4000㎜/min Amount of movement(pick) :15㎜ Depth of cut :10㎜ |

|---|---|

| Processing | Cutter diameter :20㎜ Cutter speed :10000rpm Feed speed :4000㎜/min Amount of movement(pick) :5㎜ Depth of cut :5㎜ |

| Finishing touches | Cutter diameter :10㎜ Cutter speed :7000rpm Feed speed :3000㎜/min Amount of movement(pick) :0.8㎜ Depth of cut :0.5㎜ |

Product Name:

SANMODUR MDX-M、NO7-K

Cutter Name:

High speed steel ball end mill

| Adhesive processing | Cutter diameter :20㎜ Cutter speed :16000rpm Feed speed :4000㎜/min Amount of movement(pick) :15㎜ Depth of cut :10㎜ |

|---|---|

| Processing | Cutter diameter :20㎜ Cutter speed :10000rpm Feed speed :3000㎜/min Amount of movement(pick) :5㎜ Depth of cut :5㎜ |

| Finishing touches | Cutter diameter :10㎜ Cutter speed :7000rpm Feed speed :3000㎜/min Amount of movement(pick) :0.8㎜ Depth of cut :0.5㎜ |

(2)Example of cutting conditions when carbide ball end mills are used

Product Name:

SANMODUR TW-E、VM

Cutter Name:

Ultra steel ball end mill

| Adhesive processing | Cutter diameter :20㎜ Cutter speed :16000rpm Feed speed :3500㎜/min Amount of movement(pick) :15㎜ Depth of cut :10㎜ |

|---|---|

| Processing | Cutter diameter :20㎜ Cutter speed :10000rpm Feed speed :2000㎜/min Amount of movement(pick) :5㎜ Depth of cut :5㎜ |

| Finishing touches | Cutter diameter :10㎜ Cutter speed :8000rpm Feed speed :2000㎜/min Amount of movement(pick) :0.8㎜ Depth of cut :0.5㎜ |

Product Name:

SANMODUR NZ-M、HD-M、NV

Cutter Name:

Ultra steel ball end mill

| Adhesive processing | Cutter diameter :16㎜ Cutter speed :4000rpm Feed speed :2000㎜/min Amount of movement(pick) :15㎜ Depth of cut :10㎜ |

|---|---|

| Processing | Cutter diameter :12㎜ Cutter speed :4000rpm Feed speed :2500㎜/min Amount of movement(pick) :5㎜ Depth of cut :5㎜ |

| Finishing touches | Cutter diameter :8㎜ Cutter speed :4000rpm Feed speed :2500㎜/min Amount of movement(pick) :0.8㎜ Depth of cut :0.5㎜ |

Related Information

Related Products

-

Urethane products

-

Link to Sanyo Chemical's corporate website

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist