Sulfosuccinate-type anionic surfactant (sodium dioctyl sulfosuccinate)"SANMORIN OT-70"

What's great about Sanyo Chemical's "SANMORIN OT-70", a sulfosuccinate-type anionic surfactant (sodium dioctyl sulfosuccinate)

1

Excellent wetting and penetrating power

"SANMORIN OT-70" is approximately a 70 mass% solution (containing propylene glycol and water as solvents) of a sulfosuccinate-type anionic surfactant (sodium dioctyl sulfosuccinate) that has particularly excellent penetrating power and surface tension lowering ability among surfactants.

It exhibits excellent wetting and penetrating power in applications such as metal and furniture cleaning.

2

Excellent emulsification and dispersion

"SANMORIN OT-70" has excellent emulsifying and dispersing power.

It is used for wetting and dispersion of agrochemical granules and pigments, emulsion polymerization, and emulsion breaking.

"SANMORIN OT-70" is a sulfosuccinate-type anionic surfactant (approximately 70 mass% solution of sodium dioctylsulfosuccinate) with excellent penetration and surface tension lowering ability among surfactants.

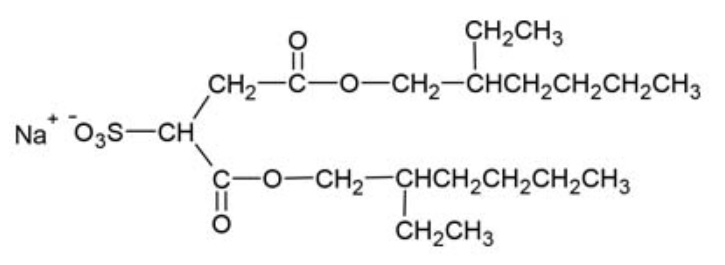

Fig. Molecular structure of the main Ingredient of "SANMORIN OT-70"

(sodium dioctyl sulfosuccinate)

| Appearance | Pale yellow liquid |

|---|---|

| pH | Approx. 6 (1 mass% aqueous solution) |

| Active ingredient | Approx. 70 mass% (evaporation residue after drying at 150°C for 90 min) |

Sulfosuccinate-type anionic surfactant (sodium dioctyl sulfosuccinate) "SANMORIN OT-70" Application Examples

Household cleaners

When "SANMORIN OT-70" is added as an ingredient to household cleaning agents, it improves the cleaning power by increasing the penetration of grease and other contaminants on ventilation fans and stove tops.

Example of Stove Top Cleaner Formulation

| Ingredient name | Amount (by mass) |

|---|---|

| SANMORIN OT-70 (Sulfosuccinate type anionic surfactant) | 0.4 |

| Ethanol | 30.0 |

| Isopropylcarbitol | 10.0 |

| Water | remaining quantity |

| Total amount | 100.0 |

Wettability improver for paper coating liquids

"SANMORIN OT-70" is used to improve the wettability of the coating solution on paper during the production of coated paper.

"SANMORIN OT-70" is added to the coating solution. The amount added varies depending on the coating solution formula and the type of paper, but generally ranges from 20 to 100 ppm for paper.

Emulsifier for emulsion polymerization of styrene

"SANMORIN OT-70" is used as an emulsifier for emulsion polymerization alone or in combination with a nonionic surfactant, and is suitable for emulsion polymerization of emulsions with large particle size.

Pigment dispersants for paints and inks

"SANMORIN OT-70" is suitable as a dispersing agent for waterborne and emulsion paints. It provides high wetting properties for hydrophobic pigments.

Agricultural applications

Disintegrant spreader (dispersant and binder) for agrochemical granule formulation: It has excellent penetrating power among surfactants and imparts disintegration and spreading properties to granule formulations.

Base for agrochemical spreaders: Provides spreading properties to plants and insects.

Performance data of sulfosuccinate-type anionic surfactant (sodium dioctyl sulfosuccinate) "SANMORIN OT-70"

Permeability

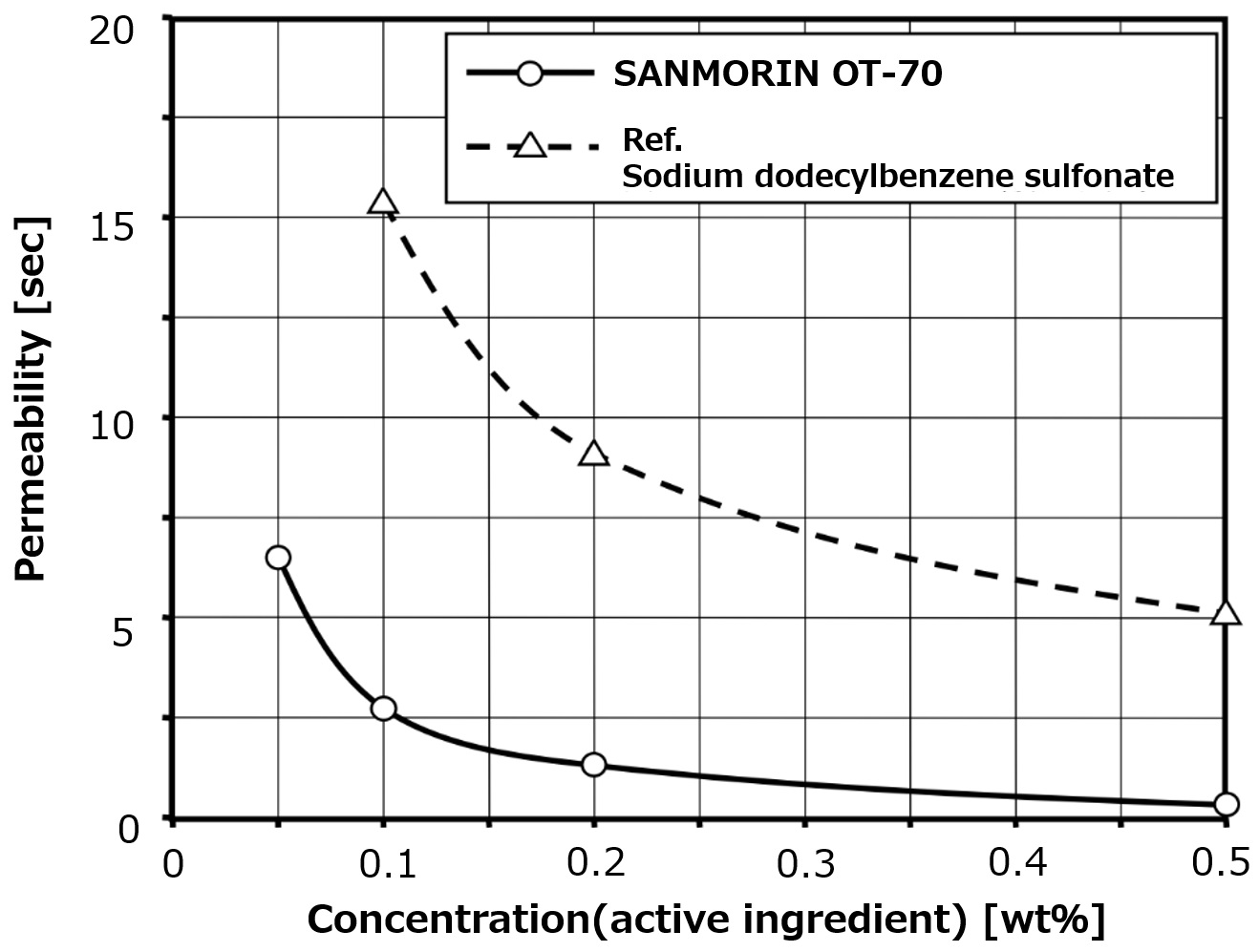

As shown in the figure below, "SANMORIN OT-70" has excellent permeability.

Fig. Relationship between concentration (active ingredient) and penetration power of "SANMORIN OT-70"

Test Method

Sample

Samples were prepared by diluting "SANMORIN OT-70" and sodium dodecylbenzenesulfonate with water to the prescribed concentration (active ingredient).

Measuring method

A degreased cotton canvas piece (15 x 15 x 0.7 mm) was gently placed on the solution surface at 20°C, and the time required for the cotton canvas piece to submerge under the water and begin to sink was measured.

The shorter time required means better permeability.

Surface tension lowering capacity

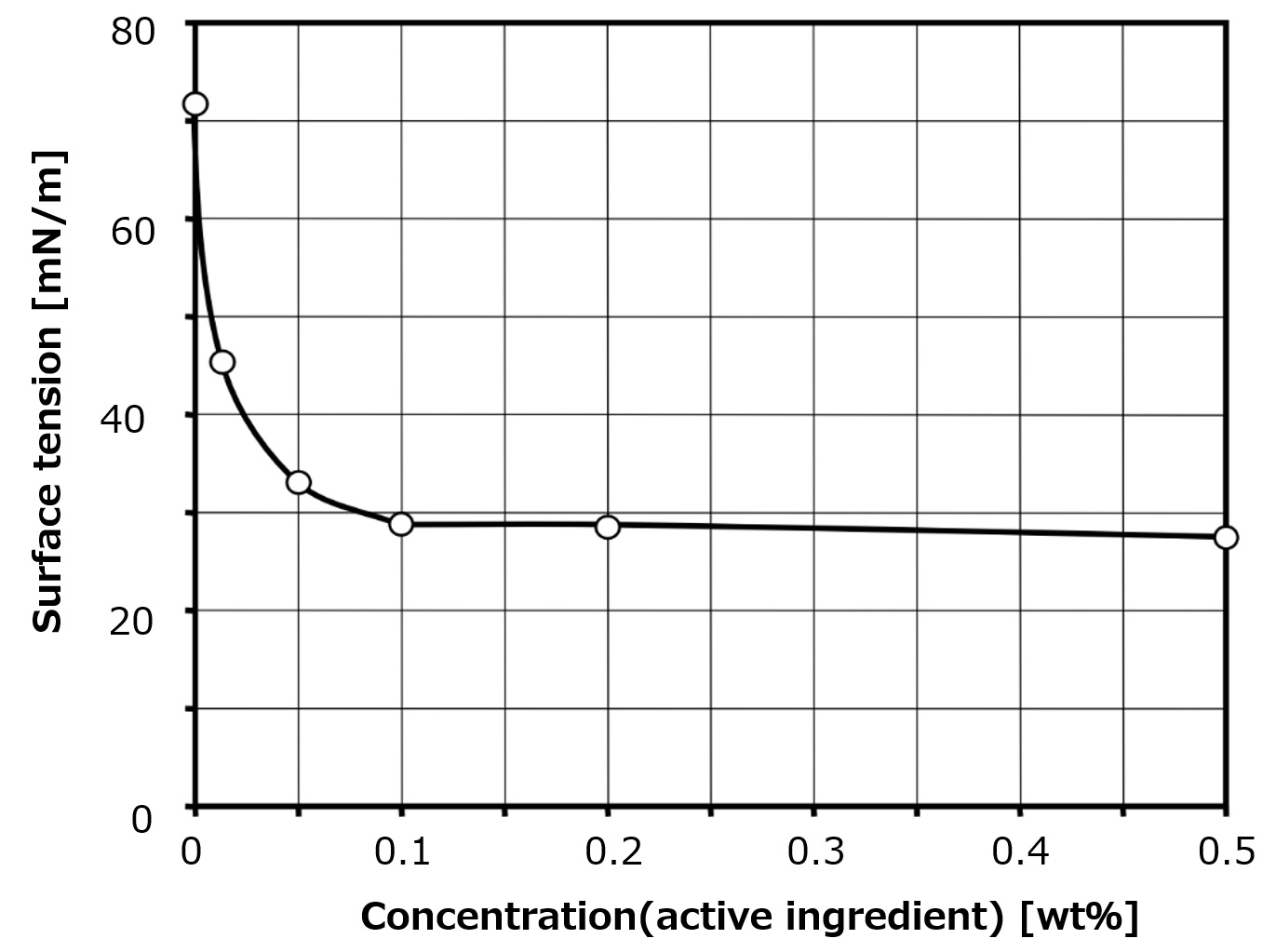

As shown in the figure below, "SANMORIN OT-70" has excellent surface tension lowering ability.

Fig. Relationship between concentration (active ingredient) and surface tension of "SANMORIN OT-70"

Test Method

Sample

Samples were prepared by diluting "SANMORIN OT-70" to the prescribed concentration (active ingredient) with water.

Measuring method

The surface tension of the sample was measured at 25°C using a Wilhelmy-type automatic surface tension meter [CBVP-A3 type manufactured by Kyowa Interface Science Co., Ltd.

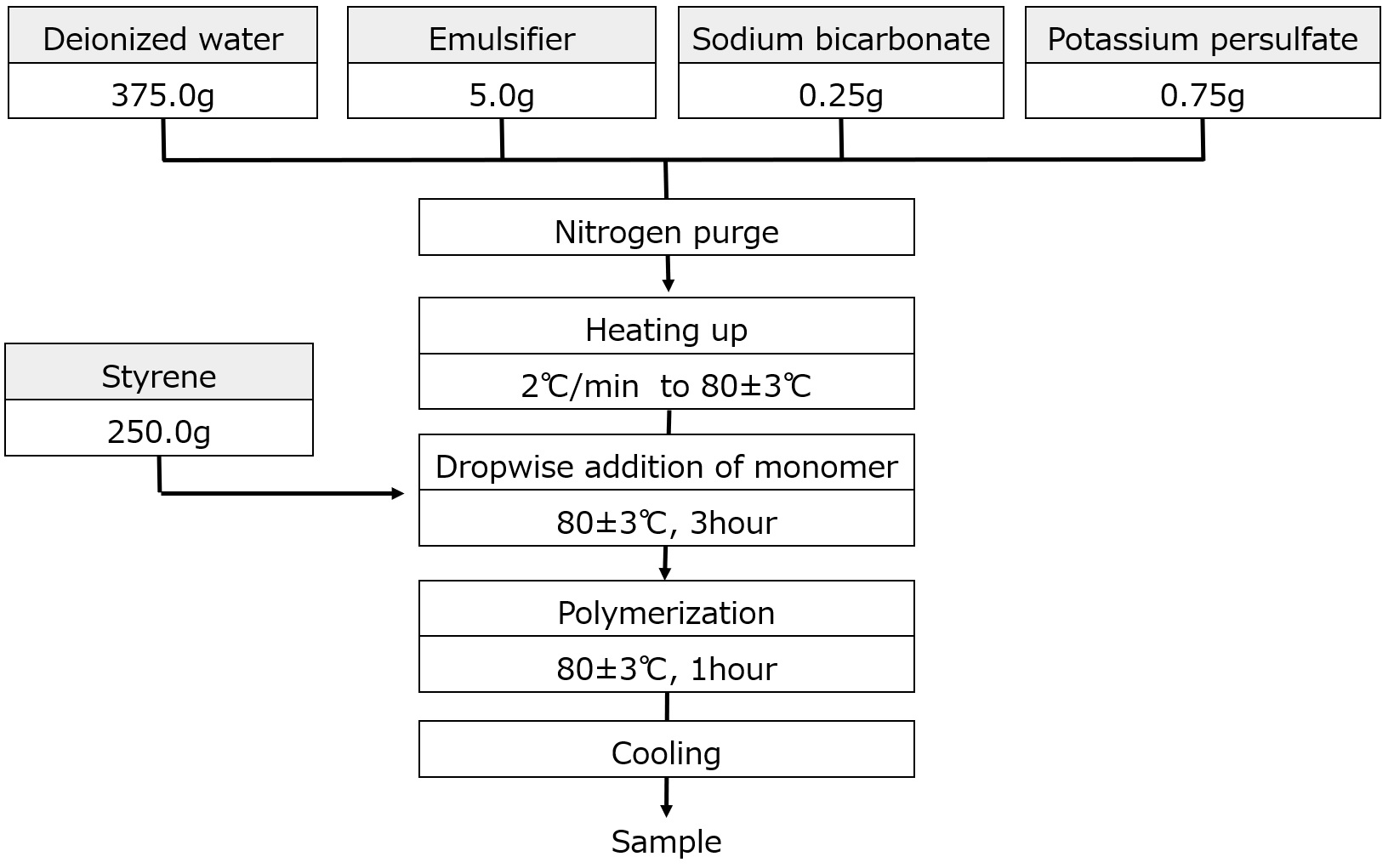

Emulsification power as emulsifier for emulsion polymerization of styrene

The following table shows the emulsifying power of "SANMORIN OT-70" when used as an emulsifier for styrene emulsion polymerization.

Comparative evaluation results of emulsifying power

| Measured items\Emulsifiers | SANMORIN OT-70 Sodium dioctyl sulfosuccinate |

Ref. Sodium lauryl sulfate |

Ref. Sodium dodecylbenzenesulfonate |

|---|---|---|---|

| Monomer polymerization conversion mass% |

99 | 99 | 99 |

| Viscosity of polymer emulsion mPa・s(25°C) |

150 | Not measurable because of gelation during polymerization |

Not measurable because of gelation during polymerization |

| Particle size of polymer emulsion (μm) |

Less than 0.1 | ||

| Stability of polymer emulsion (25℃) |

Stable for more than 1 year |

Test Method

Sample

Polymer emulsions prepared by the method shown below were used as samples.

Fig. Sample preparation method

Sample preparation method

Method of measuring monomer polymerization conversion

After drying the sample at 130°C for 90 minutes, the mass of the sample was measured, and the percentage of the mass to the theoretical evaporation residue of the polymer emulsion was defined as the monomer polymerization conversion.

Method of Measuring Viscosity of Polymer Emulsion

The viscosity was measured using a BL viscometer at 25°C and 60 rpm.

Method of Measuring Particle Size of Polymer Emulsion

The cumulant average particle size of emulsion particles in the sample was measured by dynamic light scattering.

Method of measuring the stability of polymer emulsions

Samples were stored in a thermostatic oven at 25°C, and their appearance was visually judged at each predetermined period.

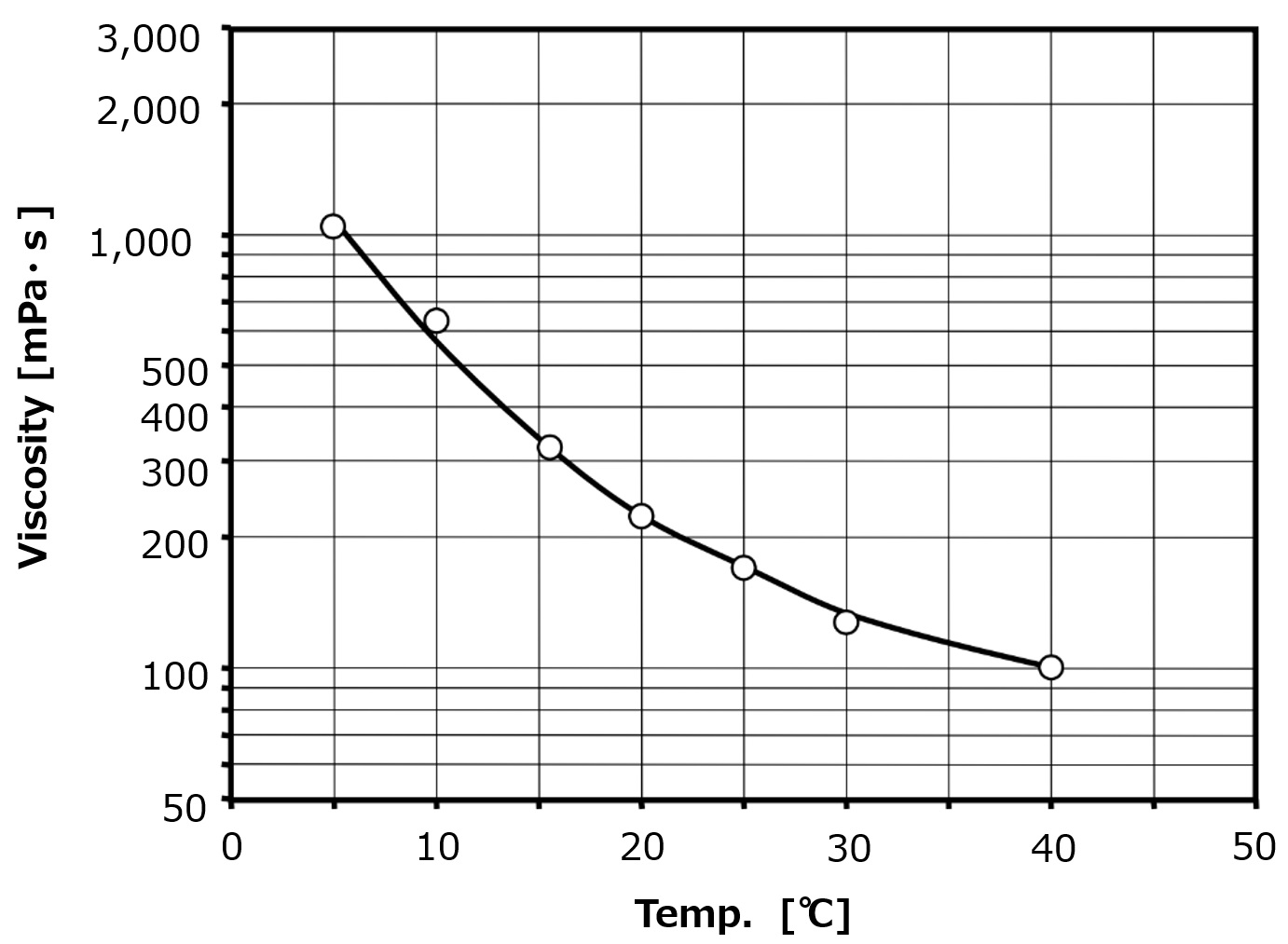

Temperature-viscosity curve of "SANMORIN OT-70"

The temperature-viscosity curve of "SANMORIN OT-70" is shown below.

Fig. Temperature-viscosity curve of "SANMORIN OT-70"

[Test Method]

Sample

The sample was "SANMORIN OT-70".

Measuring method

The viscosity of the sample was measured at a specified temperature using a BL viscometer.

Usage

It can be used alone or in combination with other surfactants (except cationic surfactants) as a wetting agent, penetrating agent, household or industrial cleaner, emulsifier, or dispersant.

Concentrations vary depending on the application and the type of agent used in combination, but the standard range is 0.05-10% by mass.

Precautions against misuse

"SANMORIN OT-70" is an anionic agent. If it is used in combination with a cationic agent, it may cause agglomerates and fail to perform as expected. Do not use "SANMORIN OT-70" together with cationic agents.

If "SANMORIN OT-70" is used under strongly alkaline or acidic conditions, it may lose its effectiveness due to hydrolysis. Do not use "SANMORIN OT-70" under strongly alkaline or acidic conditions.

Before handling this product, be sure to read the "Safety Data Sheet" (SDS) for this product and its sub-materials (chemicals). The SDS can be obtained here.https://www.sanyo-chemical.co.jp/products/en/sds/

Related Information

Related Products

-

Link to Sanyo Chemical's corporate website

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist