Water-soluble metalworking oil base"UTILIOL"

Water soluble cutting oil base with both lubricity and low foaming

What's great about Sanyo Chemical's water-soluble cutting oil base

"UTILIOL".

1

Water-soluble polyether with excellent galling resistance

Water-soluble metalworking oils are nonflammable, present a low risk of fire, have excellent cooling properties, and contribute to an improved working environment and reduced environmental impact.

"UTILIOL GA-15P" is a water-soluble polyether with excellent galling resistance, suitable as a base for water-soluble metalworking oils.

2

Combination of lubricity and low foaming

Compared to our general-purpose polyether base, "UTILIOL GA-15P" has significantly improved lubricity while maintaining the features of water-soluble metalworking oils. The combination of lubricity and low foaming, which had been an issue with water-soluble processing oils, provides benefits such as reduced environmental impact, improved working environment, and improved cooling efficiency.

3

Capable of machining difficult-to-machine materials such as highly ductile aluminum

"UTILIOL GA-15P" has excellent lubricity, making it applicable for machining difficult-to-machine materials such as aluminum, which is highly ductile.

4

High transparency of processing solution diluted with water

"UTILIOL GA-15P" does not impair visibility due to the high transparency of the processing solution diluted with water.

5

High handling performance

"UTILIOL GA-15P" is a water-soluble polyether base agent with low viscosity, high cloud point, and is non-applicable to hazardous materials under the Fire Service Law, making it easy to store and handle.

Why is low foaming important in water soluble processing oils?

Conventional water-soluble machining oils often have insufficient lubricity, while foaming is a problem when lubricity is improved. Foaming during machining leads to concerns about overflow, insufficient cooling, reduced workability due to difficulty in seeing the machining point, poor machining, and increased use of machining oil.

⇒"UTILIOL GA-15P", which has both lubricity and low foaming, can be used in applications where water-soluble processing oil could not be used due to the above problems.

Intended use

Machine tool lubricants are used in a wide variety of metalworking processes such as cutting, rolling, drawing, pressing, and forging, and their basic functions are lubrication and cooling.

The lubricant reduces friction by entering the gap between the tool and the workpiece or chips, and the cooling effect of the lubricant suppresses heat generated by friction, thereby reducing tool wear and deformation, preventing burning and extending tool life, as well as improving machining accuracy.

1

Cutting process

2

Rolling process

3

Drawing process

4

Pressing process

Properties of "UTILIOL"

"UTILIOL GA-15P" is a water-soluble polyether base agent with low viscosity, high cloud point, and easy storage and handling.

| Polyether base (Our product) | UTILIOL GA-15P | NEWPOL GEP-2800 | NEWPOL PE-61 | BLEMBER LUB-90 |

|---|---|---|---|---|

| Appearance | liquid state | liquid state | liquid state | liquid state |

| Cloud point (1wt%aq.) ℃ | 52 | 74 | 24 | 7 |

| Kinematic viscosity (40°C) mm2/s | 263 | 198 | 144 | 461 |

| Flash Point ℃ | 255 | 240 | 210 | 230 |

Performance of "UTILIOL" as a water-soluble cutting oil base

The table below shows the performance when blended as a water-soluble cutting oil base (compared to our conventional products).

| Polyether base (Our product) | UTILIOL GA-15P | NEWPOL GEP-2800 | NEWPOL PE-61 | BLEMBER LUB-90 | |

|---|---|---|---|---|---|

| Appearance | liquid state | liquid state | liquid state | liquid state | |

| Cloud point ℃ *1 | 52 | > 75 | 26 | 18 | |

| Lubricity*2 | Galling resistant load N | 390 | 156 | 283 | 285 |

| Coefficient of friction (at 100N) | 0.140 | 0.157 | 0.132 | 0.135 | |

| Low foaming *1 | Bubble height (immediately after) cm | 5.2 | 8.2 | 4.5 | 5.3 |

| Bubble height (after 1min) cm | 2.9 | 7.2 | 3.0 | 3.3 | |

<Evaluation method >

Appearance: Visual, Cloud point: Visual

Galling load resistance: SRV method

Bubble height: Biomixer method

Lubricity of "UTILIOL"

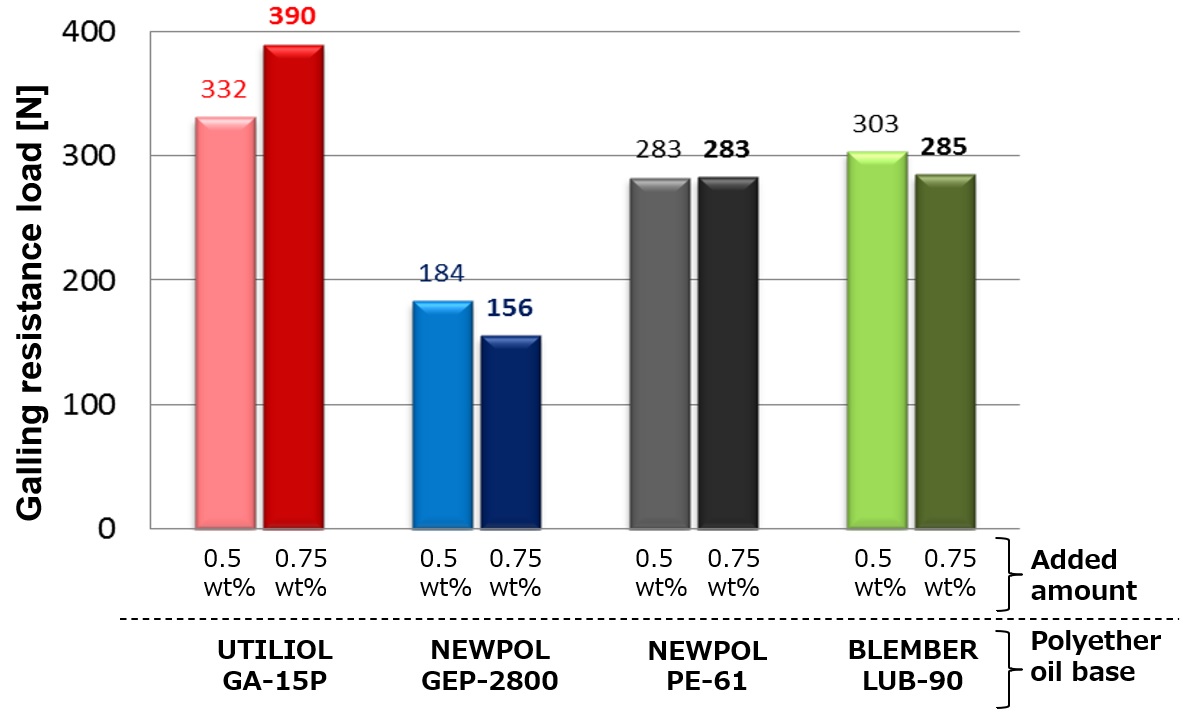

Lubricity Evaluation 1: Galling Resistance Load

Fig. Comparison of galling resistance load (SRV method)

(1) High anti-galling load

"UTILIOL GA-15P" exhibits higher galling resistance load compared to our conventional polyether base.

(2) Improved galling load resistance due to increased concentration

"UTILIOL GA-15P" can improve galling load resistance by increasing its concentration.

<Test conditions (SRV method) >

Lubricity (galling load resistance) was evaluated using an oscillating friction and wear test (SRV tester).

Sample

(Bar graph left): Mixture of each polyether base (0.50wt%), medium-chain fatty acid amine salt (2.40wt%), and water (97.10wt%)

(Right side of the bar graph): Mixture of each polyether base (0.75wt%), medium-chain fatty acid amine salt (2.40wt%), and water (96.85wt%)

Specimen : Steel ball (SUJ-2, Φ 10 mm), steel disk (SUJ-2)

Test conditions : Load 50 → 500 N, frequency 50 Hz, vibration width 1.0 mm, temperature 30°C, immersion jig used

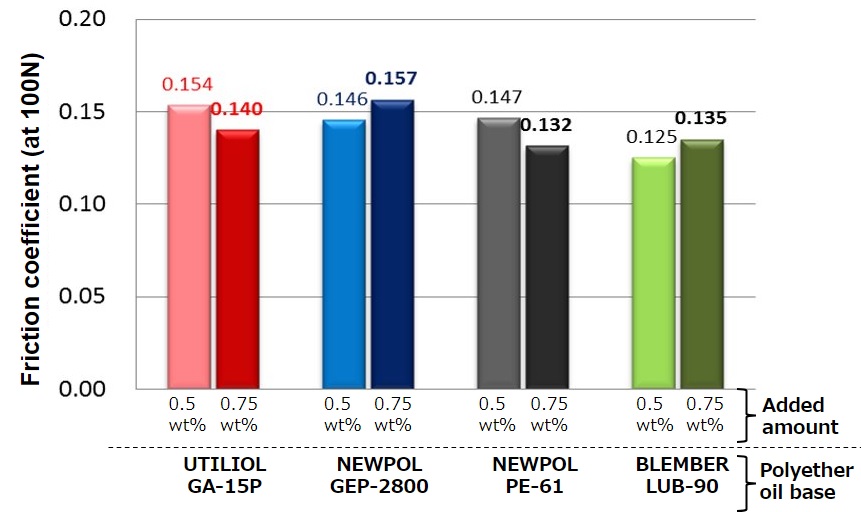

Lubricity Evaluation 2: Friction Coefficient

Fig. Comparison of friction coefficient @ 100N (SRV method)

Low coefficient of friction

"UTILIOL GA-15P" exhibits a low coefficient of friction equivalent to our conventional polyether base material.

<Test conditions (SRV method) >

Lubricity (coefficient of friction) was evaluated using an oscillating friction and wear test (SRV tester).

Sample

(bar graph left): Mixture of each polyether base (0.50wt%), medium-chain fatty acid amine salt (2.40wt%), and water (97.10wt%)

(Right bar graph): Mixture of each polyether base (0.75wt%), medium-chain fatty acid amine salt (2.40wt%), and water (96.85wt%)

Specimen : Steel ball (SUJ-2, Φ 10 mm), steel disk (SUJ-2)

Test condition : Load 100 N (50 → 500 N), frequency 50 Hz, vibration width 1.0 mm, temperature 30°C, immersion jig used

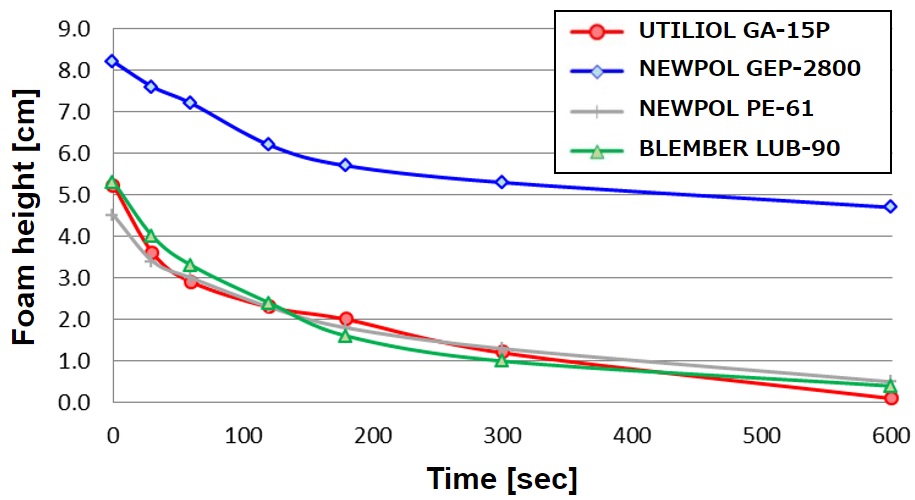

About the low-foaming properties of "UTILIOL"

Fig. Results of low-foaming evaluation (Biomixer method)

Low-foaming properties

UTILIOL GA-15P is a low-foaming polyether base.

Foam bursting speed

UTILIOL GA-15P has a superior foam-breaking rate from 0 to 60 seconds compared to our conventional polyether base.

<Evaluation Method (Biomixer Method)>

A 150mL sample was weighed into a 300mL tall beaker, and low foaming (change over time in foam height after stirring) was evaluated using a biomixer.

Sample: Mixture of each polyether base (0.50wt%), medium-chain fatty acid amine salt (2.40wt%), and water (97.10wt%)

Test conditions: Rotation speed: 11500 rpm, stirring time: 40 seconds, temperature: 23°C

Measurement time: immediately after stirring, 30 seconds after standing, 1 minute, 2 minutes, 3 minutes, 5 minutes, 10 minutes

Related Information

Related products

- Links to Sanyo Chemical's corporate site

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist.