Pressure Sensitive Adhesives Basics

What is a Pressure Sensitive Adhesive?

Pressure sensitive adhesives are a type of bonding agent that can be quickly laminated and peeled off when needed. Because of their convenience, they are widely used in various applications and fields such as packaging, electronics, optics, automobiles, construction materials, and medicine. In the electronics, optical, and medical fields, there is a particular demand for highly functional adhesives. Among these, the ability to peel off flexibly with light force and the stability of adhesive properties are among the most important functions.

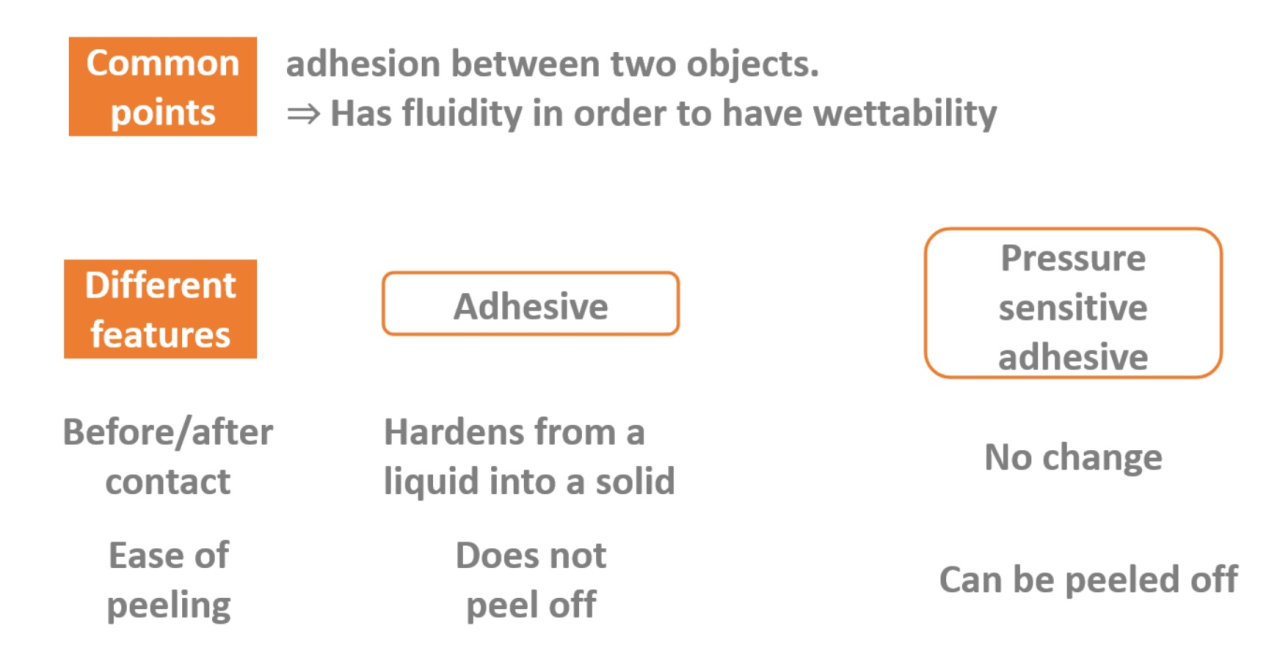

Similarities and Differences between Adhesives and Pressure Sensitive Adhesives

Although both adhesives and and pressure sensitive adhesives have the same purpose (bonding surfaces together) , pressure sensitive adhesives "do not change in state before and after contact with the adherend" and "can be peeled off after bonding”.

Properties Required for Pressure Sensitive Adhesives

| Viscosity | Force required to peel an object from an adhesive |

|---|---|

| Wettability | The ability to firmly contact (wet) the adherend (viscosity) |

| Flowability after application | Little or no flow (elasticity) |

| Tack | Sticky to the touch |

| Holding power | The ability to maintain adhesion and withstand shear |

| Re-sealability | The ability to peeled off without adhesive residue. The requirements are that the adhesion is by physical bonding and that the state of the adhesive does not change before and after contact. |

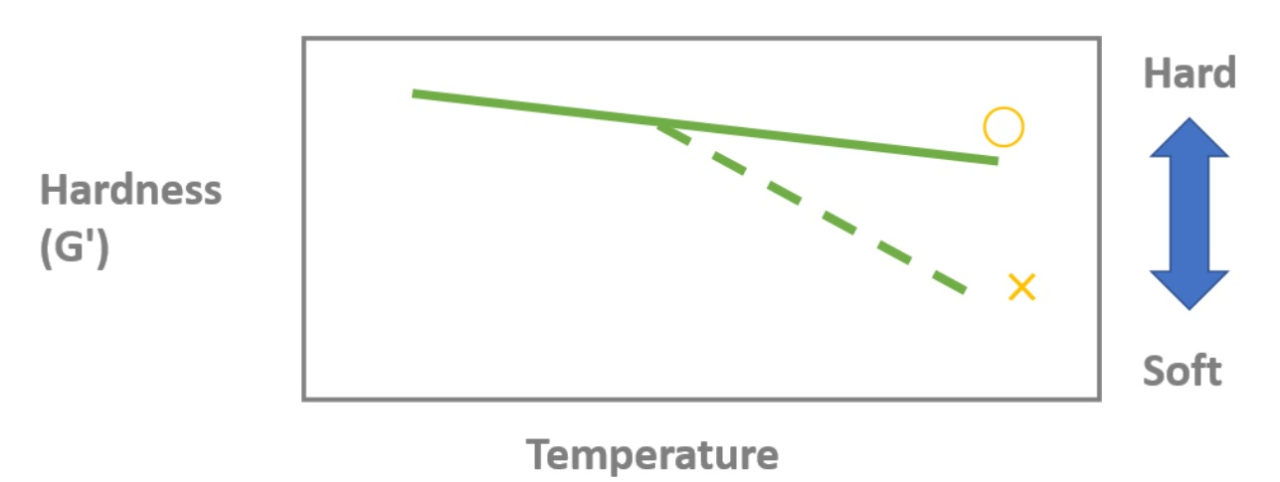

| Small dependence on external factors | Minimal change in adhesive bonding and peeling characteristics due to external factors such as time, temperature, and peeling speed. In the case of temperature, the hardness of the adhesive should be constant over a wide temperature range (index of hardness is the storage modulus (G')). |

Pressure Sensitive Adhesive Design Guidelines

Guideline for Increasing Adhesive Strength and Retention

To increase adhesive strength and retention, the higher the storage modulus (G') of the adhesive , the better.

However, if the elastic modulus becomes too high, the adhesive becomes too hard as an adhesive and the contribution to viscosity is reduced, resulting in a lack of adhesion at the interface with the adherend, so there are peaks in the retention and elastic modulus.

Guideline for improving removability

To ensure that peeling occurs only at the interface between the adhesive and the adherend, and that there is no glue residue or damage to the adherend, the adhesive should have high cohesive strength, and its composition should be designed to provide adhesive characteristics suitable for the purpose.

Types of Pressure Sensitive Adhesives and Their Characteristics

Adhesives are generally acrylic-based, rubber-based, silicone-based, and urethane-based.

Acrylic-based and rubber-based adhesives

- The most widely used because they can be designed in a wide range from fine adhesion to strong adhesion and are relatively inexpensive.

- Highly dependent on external factors such as time, temperature, and peeling speed.

Silicone-based

- Relatively small dependence on external factors such as time, temperature, and peeling speed, and stable adhesion in a wide range of environments.

- Expensive.

- There is concern that low-molecular-weight silicone components may migrate to the adherend and cause contamination.

Urethane adhesive

- Small dependence on time, temperature, peeling speed, etc.

- Excellent oil resistance and abrasion resistance.

- Due to the high polarity of the urethane group, it excels in wettability and adhesion to the adherend, has high moisture permeability, and can easily develop antistatic properties. ⇒ Especially strong in micro-adhesive applications where removability is important.

Temperature Dependence of Hardness in Urethane Adhesives

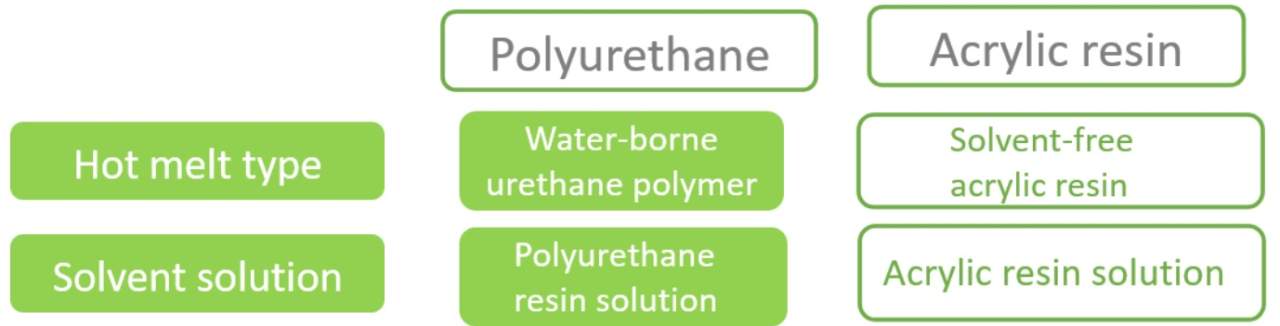

Classification of our adhesives by form and composition

The table below shows the classification of our adhesives by properties, usage form and composition.

We possess design and synthesis technologies for polyurethane resin and acrylic resin-based adhesives, and are specialized in both solventless hot-melt and solvent solution types, enabling us to respond to a variety of applications and needs.

References

- Sanyo Chemical News No. 440

- Sanyo Chemical News No. 509

- Sanyo Chemical News No. 511

- Our Performance Chemicals and Chemicals Function Series No. 3

Related Information and Topics

Related Products

Click here for the product introduction page for POLYTHICK acrylic adhesive base agent

Click here for the product introduction page for POLYTHICK UP urethane adhesive