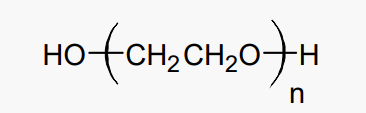

Polyethylene glycol"PEG"

Polyethylene glycol (PEG) that can add a variety of functions.

Wide range of products with various molecular weights.

What are Great about Sanyo Chemical's Polyethylene Glycol "PEG"

1

Water-soluble polymers with a wide range of applications

PEG is highly water soluble and is not hydrolyzed, so it is widely used as a water soluble base for viscosity adjustment and other applications.

The solubility of PEG in water is not affected by the presence of electrolytes. It is soluble in hard water and aqueous solutions of salts, as well as acids and alkalis (except for extremely concentrated acids and alkalis).

2

A wide range of molecular weight products are lined up to provide a variety of functions

Polyethylene glycol (PEG) can provide various functions depending on its molecular weight, such as smoothing, lubrication, thickening/thickening, plasticization, emulsification/dispersion, heat storage, moisture retention, binding, and antistatic.

For example, PEG with high molecular weight is used as a water-soluble binder, PEG with low molecular weight is used as a plasticizer, and PEG is also used as a dispersant, lubricant, heat medium, sensitizer, dust-proofing agent, etc., to express functions suitable for a variety of applications.

(For details, please refer to "Major Applications" and "Relationship between Molecular Weight and Applications" below.)

3

Active as a raw material for many chemical products

Both ends of polyethylene glycol (PEG) are primary alcohols, making it easy to esterify and etherify.

In addition to surfactants, PEG is used as a raw material for numerous chemical products, not limited to polyesters and polyurethanes.

4

Highly Safe

Polyethylene glycol (PEG) is a highly safe compound with low irritation and toxicity.

(Polyethylene glycol for the pharmaceutical industry is separately lined up as "MACROGOL" in the Japanese Pharmacopoeia.

Our "MACROGOL" is a pharmaceutical product for manufacturing only. If you need samples for testing and research or the local formulation, please contact the reagent manufacturer or the local formulation manufacturer).

https://www.sanyo-chemical.co.jp/products/en/pdf/ES20000009A.pdf

"PEG"s are a polyethylene glycol compounds that are used in a variety of fields.

"PEG"

Polyethylene glycol

Sanyo Chemical offers a broad lineup of products ranging from low molecular weight "PEG"s to high molecular weight "PEG"s.

| Average molecular weight | |||

|---|---|---|---|

| small | middle | large | |

| Polyethylene glycols (Number average molecular weight:Mn) | PEG-200 (200) PEG-300 (300) PEG-400 (400) PEG-600 (600) PEG-1500* (550) | PEG-1000 (1000) PEG-1540 (1450) PEG-2000 (2000) | PEG-4000N (3100) PEG-4000S (3400) PEG-6000S (8300) PEG-6000P (8600) PEG-10000 (11000) PEG-13000 (13000) PEG-20000 (20000) |

| Appearance | Liquid or paste | wax (solid) | flake or powder |

Main Applications of Polyethylene Glycol "PEG"

1

Pharmaceuticals

For the pharmaceutical industry, it is handled separately under the name of "MACROGOL" in the Japanese Pharmacopoeia. For details, please refer to the introduction page of "MACROGOL".

https://www.sanyo-chemical.co.jp/products/en/pdf/ES20000009A.pdf

https://www.sanyo-chemical.co.jp/eng/wp/wp-content/uploads/2021/02/PC_No.136.pdf

* Our "MACROGOL" is a pharmaceutical product for manufacturing only. If you need samples for testing and research or local products, please contact the reagent manufacturer or local product manufacturer.

2

Cosmetics and toiletries

Water-soluble Base Agents

Polyethylene glycol (PEG) is safe and water-soluble, so PEG₋1500 can be used as a water-soluble base for cosmetic creams and hand creams, and PEG-400 as a water-soluble base for lotion.

Moisturizers

Polyethylene glycols with small molecular weight such as PEG-300, PEG-400, and PEG-600 are rich in moisturizing properties and can be used as moisturizers for toothpaste, facial cleansing foam, hair care products, and wet wipes.

Binders

PEG-4000S, PEG-6000S, and other PEGs with large molecular weights have a high binder effect and are water soluble, so they can be used as binders for solid face powders and enzymes for detergents.

Anti-caking agent for powedered detergents

PEG-6000S can be used as an anti-caking agent for powdered detergents.

Anti-cracking agent

PEG-6000S can be used as an anti-cracking agent for solid soap.

Anti-clogging agent for liquid detergent

When PEG-200 or PEG-300 is added to liquid detergents such as kitchen detergents, it acts as an anti-clogging agent for liquid detergent containers.

Dust Preventive Agent

PEG-6000S can be used as a dust inhibitor for powder products such as powder cosmetics and powder detergents.

3

Textile

Antistatic Agent

PEG-2000, PEG-4000S, and PEG-6000S can be used as antistatic agents for polyester fibers.

Dyeability modifier

Copolymerization with PEG-1000 and PEG-2000 produces polyester with excellent dyeability.

Glue agent

When polyester, nylon, rayon, and other fabrics are glued and sewn, the glue sometimes sticks to the needle and interferes with the sewing process. It is also effective in preventing the glue from sticking to the fabric.

Punching agent

PEG-400, PEG-600, and PEG-1000 can be used as drilling agents for hollow and porous fibers.

4

Paper Manufacturing

Paper Softeners

Polyethylene glycol (PEG) is suitable as a paper softener and its low volatility ensures a long-lasting softening effect; PEG-200, PEG-300, and PEG-400 are especially suitable as softeners for PVA films and cellophane.

Lubricants

PEG-1540 and PEG-4000S can be blended with starch or protein glue and used as lubricants in calenders in the papermaking process.

Anti-curl agent

When paper is impregnated with PEG-400, curling of paper can be prevented by its moisture retention effect.

5

Rubbers

Internal Lubricant

Adding PEG-4000S to natural and synthetic rubbers during mixing improves flowability, dispersion of fillers such as carbon black, and improves vulcanization speed. In addition, it facilitates the release of rubber from the mold during demolding.

Lubricant for Molding

PEG-4000S can be used as a lubricant when molding natural or synthetic rubber. After molding, PEG can be easily removed from the rubber surface by washing with water.

6

Resins

Lubricants

PEG-6000S can be used as a lubricant for nylon and polyacetal(POM) resins.

Resin processing bath

Since PEG-400 is water soluble, it is easy to clean when used in heating baths for bending PVC pipes.

Plasticizers

PEG-4000S can be used as a plasticizer for urea resin.

Antistatic agent

PEG-4000S and PEG-6000S can be used as kneading antistatic agents for polyester resin, ABS resin, nylon and polyacetal resin.

Resin Modifier

PEG-4000S and PEG-6000S can modify polyester, alkyd, and polyurethane resins by utilizing hydroxyl groups at both ends of PEG to impart flexibility and hydrophilic properties.

7

Metals

Lubricant

PEG-20000 has particularly good lubricity and can be used as a water-soluble press oil base for press working of steel plates.

Quenching oil base

PEG-20000 in aqueous solution has excellent slow cooling properties for steel during quenching, so it can be used as a base for water-soluble quenching oil.

Binders and dust suppressants

PEG-4000S can be used as a binder in powder metallurgy manufacturing using metal powders and as a dust inhibitor for aluminum oxide abrasives.

8

Ceramics

Binder

Mixing PEG-4000S or PEG-6000S with aqueous solutions of polyvinyl alcohol, polyvinyl acetate, or gum arabic in ceramic materials makes them sticky and easy to mold, and prevents them from cracking. When PEG-20000 is used as a binder for fine ceramics, it provides good dispersibility and shape retention, and leaves no sludge after firing.

9

Wood

Crack Preventive Agent

When wood is soaked in an aqueous solution of PEG-600 or PEG-1000, the moisture in the wood is replaced by polyethylene glycol, resulting in smaller dimensional changes and less susceptibility to cracking. In addition, for preservation, deformation of the buried cultural properties can be prevented. deformation of wooden artifacts in archeological sites can be prevented if the moisture is replaced with PEG 4000S for preservation.

10

Agrochemicals

Binder

PEG-6000S can be used as a binder for agrochemical granules.

Formulation Auxiliaries

Effective in adjusting the flowability and preventing caking of powders as well as flowable and dry agrochemical formulations.

11

Chemicals

Raw Materials for Surfactants

Various surfactants can be synthesized using the hydroxyl groups at both ends of polyethylene glycol (PEG). Among them, esterified products with higher fatty acids are typical surfactants used as emulsifiers, dispersants, and detergents.

Raw materials for chemical products

The hydroxyl groups at both ends of PEG are modified (alkyl etherification, amination, carboxylation, glycidyl etherification, esterification, etc.) and used as raw materials for chemical products.

12

Other

Viscosity Regulators

Using PEG-600 or PEG-1000 as a viscosity adjuster for ballpoint pen inks improves ink performance.

Thermal media

PEG-400 and PEG-600 have high boiling point and specific heat and good thermal stability, so they can be used as heat transfer media. They are also easily soluble in water, making them easy to clean.

Sensitizers

PEG-400 can be mixed with saturated aliphatic polyhydric alcohols, etc. and used as a sensitizer to improve the sensitivity and contrast of photosensitive films.

Thermal storage agent

Polyethylene glycol (PEG) is suitable as a heat storage agent because of its high heat of fusion.

Cold storage agent

PEG-200 is water soluble and has a low freezing point, so it can be used as a base agent for cold insulators.

Relationship between molecular weight of polyethylene glycols and applications

| Polyethylene glycols with low molecular weight | Polyethylene glycols with middle molecular weight | Polyethylene glycols with high molecular weight | |

|---|---|---|---|

| Cosmetics and toiletries | Base for cream | Base for cream | Binders for solid face powder or enzymes for detargents |

| Textile | - | Dye improver | Antistatic agent |

| Paper Manufacturing | Fabric softener | Lubricant | Fabric softener |

| Rubbers | - | - | Lubricant |

| Resins | - | - | Lubricant Plasticizers Antistatic agent |

| Metals | - | - | Lubricants Hardening Substrate |

| Ceramics | - | Binder | Binder |

| Wood | Crack prevention agent | Crack prevention agent | Crack prevention agent |

| Agrochemicals | - | - | Granule binder |

| Chemicals | Various raw materials | Various raw materials | Various raw materials |

| Other | Heat transfer medium Desulfurization auxiliaries Refrigerant | - | Heat accumulator |

Main Lineup of Sanyo Chemical's Polyethylene Glycol "PEG"

Physical properties of "PEG" (1)

| Average molecular weight *1 | Hydroxyl value *2 | pH *3 | Color number *4 | Freezing point ℃ | Appearance | |

|---|---|---|---|---|---|---|

| PEG-200 | 200 | 565 | 6.0 | 10 | <-35 | Colorless liquid |

| PEG-300 | 300 | 375 | 5.5 | 10 | <-8 | |

| PEG-400 | 400 | 281 | 5.5 | 10 | 6 | |

| PEG-600 | 600 | 187 | 6.0 | 10 | 21 | |

| PEG-1000 | 1,000 | 113 | 6.5 | 10 *6 | 37 | White wax-like |

| PEG-1500 *5 | 550 | 207 | 5.5 | 10 *6 | 40 | White paste |

| PEG-1540 | 1,450 | 79 | 6.0 | 10 *6 | 45 | White wax-like |

| PEG-2000 | 2,000 | 56 | 5.5 | 10 *6 | 51 | |

| PEG-4000N | 3,100 | 36 | 6.5 | 10 *6 | 55 | White flakes |

| PEG-4000S | 3,400 | 33 | 6.5 | 10 *6 | 56 | |

| PEG-6000P | 8,300 | 13 | 7.0 | 10 *6 | 58 | White powder |

| PEG-6000S | 8,300 | 14 | 6.5 | 10 *6 | 59 | White flakes |

| PEG-10000 | 11,000 | 10 | 6.5 | 10 *6 | 59 | |

| PEG-20000 | 20,000 | 5.6 | 7.0 | 10 *6 | 60 |

*1 Value obtained from hydroxyl value

*2 Pyridine acetate anhydride method

*3 Measured in 5 mass% aqueous solution

*4 APHA

*5 Mixture of PEG-300 and PEG-1540

*6 Measured in 25 mass% aqueous solution

Physical properties of "PEG" (2)

| Specific gravity (25℃/25℃) | Kinematic viscosity ㎜2/s (210°F) | Flash Point ℃ | Vapor pressure Pa (100℃) | Specific heat kJ・㎏₋1K-1 | Heat of melting kJ/kg | Refractive index (25℃) | Surface tension mN/m (25℃) | |

|---|---|---|---|---|---|---|---|---|

| PEG-200 | 1.125 | 4.1 | 196 | 1.3 | 2.2 *7 | - | 1.458 | 44.5 |

| PEG-300 | 1.125 | 5.6 | 225 | 3.9×10‐1 | 2.2 *7 | 160 | 1.462 | 44.5 |

| PEG-400 | 1.125 | 7.1 | 230 | 1.2×10‐2 | 2.2 *7 | 150 | 1.465 | 44.5 |

| PEG-600 | 1.125 | 10 | 246 | 6.9×10‐4 | 2.2 *7 | 150 | 1.467 | 44.5 |

| PEG-1000 | - | 17 | 250 | 4.4×10‐7 | 2.3 *8 | 160 | - | - |

| PEG-1500 *5 | - | 16 | 240 | - | 2.3 *8 | 160 | - | - |

| PEG-1540 | - | 26 | 256 | 2.7 ×10‐10 | 2.3 *8 | 180 | - | - |

| PEG-2000 | - | 42 | 260 | <2.7 ×10‐10 | 2.3 *8 | 180 | - | - |

| PEG-4000N | - | 80 | 270 | - | 2.3 *8 | 180 | - | - |

| PEG-4000S | - | 80 | 265 | - | 2.3 *8 | 180 | - | - |

| PEG-6000P | - | 800 | 256 | - | 2.3 *8 | 190 | - | - |

| PEG-6000S | - | 800 | 256 | - | 2.3 *8 | 190 | - | - |

| PEG-10000 | - | 2,100 | 260 | - | 2.4 *8 | 190 | - | - |

| PEG-20000 | - | 14,000 | 296 | - | 2.5 *8 | 190 | - | - |

*7 Average value from 30 to 60°C

*8 Average value from freezing point to 100°C

Physical Property Data of Sanyo Chemical's polyethylene glycol "PEG"

Polyethylene glycol (PEG) solubility

| PEG-400 | PEG-1540 | PEG-4000S | PEG-20000 | ||||

|---|---|---|---|---|---|---|---|

| 20℃ | 50℃ | 20℃ | 50℃ | 20℃ | 50℃ | 20℃ | |

| water | A | A | A | A | B | A | C |

| methanol | A | A | A | A | C | A | C |

| ethanol | A | A | D | A | D | A | D |

| acetone | A | A | B | A | D | A | D |

| ethyl acetate | A | A | C | A | D | A | D |

| toluene | A | A | C | A | D | A | D |

| ethylcellosolve | A | A | D | A | D | A | D |

| butylcellosolve | A | A | D | A | D | B | D |

| ethyl carbitol | A | A | C | A | D | B | D |

| butyl carbitol | A | A | D | A | D | B | D |

| heptane | D | D | D | D | D | D | D |

| ethyl ether | D | D | D | D | D | D | D |

Explanation of symbols

A:100g or more dissolved in 100mL of solvent.

B:50g or more but less than 100g in 100mL of solvent.

C:1g or more but less than 50g in 100mL of solvent.

D:Less then 1g in 100mL of solvent.

Polyethylene glycol (PEG) compatibility

| PEG-400 | PEG-1500 | PEG-4000S | |

|---|---|---|---|

| nitrocellulose | Compatible | Compatible | Partially compatible |

| ethylcellulose | Incompatible | Incompatible | Incompatible |

| methylcellulose | Partially compatible | Incompatible | Incompatible |

| shellac | Partially compatible | Partially compatible | Incompatible |

| carnauba wax | Incompatible | Incompatible | Incompatible |

| paraffin rubber | Incompatible | Incompatible | Incompatible |

| clandestine wax | Incompatible | Incompatible | Incompatible |

| ester rubber | Incompatible | Incompatible | Incompatible |

| rosin | Compatible | Partially compatible | Partially compatible |

| gum arabic | Incompatible | Incompatible | Incompatible |

| castor oil | Incompatible | Incompatible | Incompatible |

| (Chinese) wood oil | Incompatible | Incompatible | Incompatible |

| mineral oil | Incompatible | Incompatible | Incompatible |

| olive oil | Incompatible | Incompatible | Incompatible |

| casein | Compatible | Compatible | Partially compatible |

| gelatine | Incompatible | Incompatible | Incompatible |

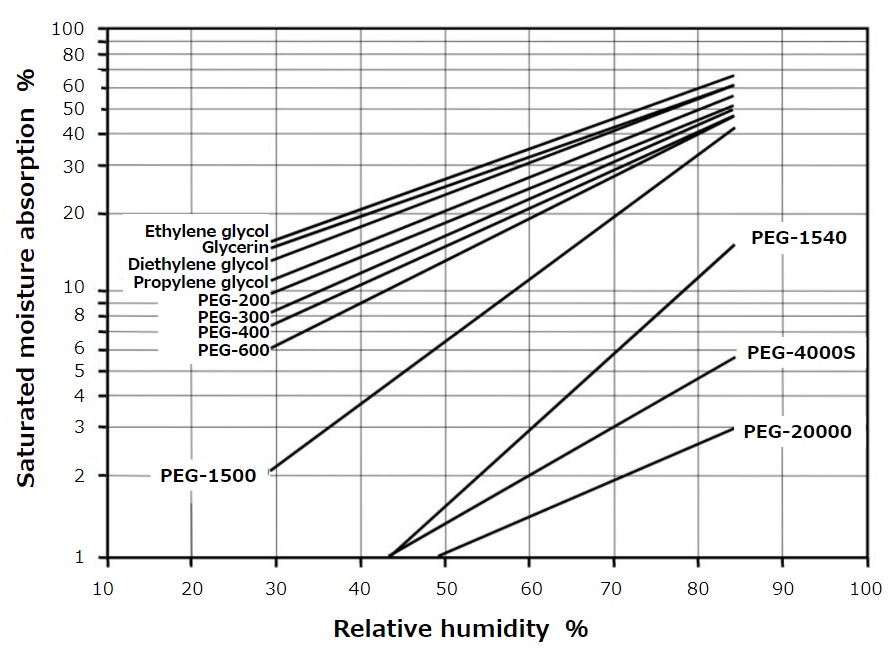

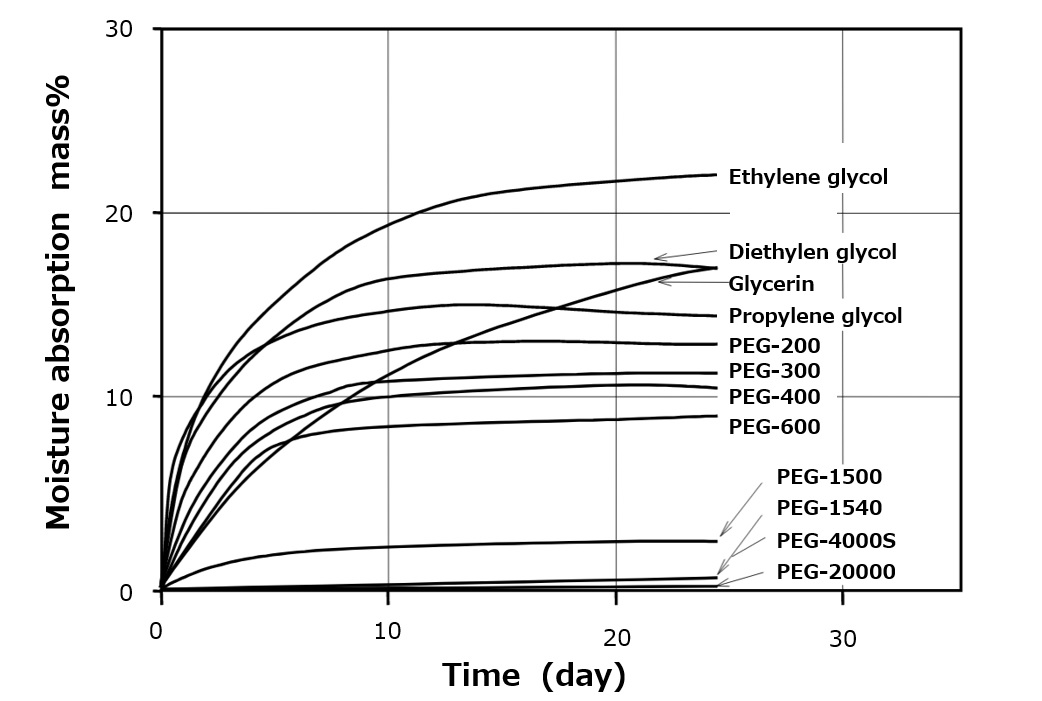

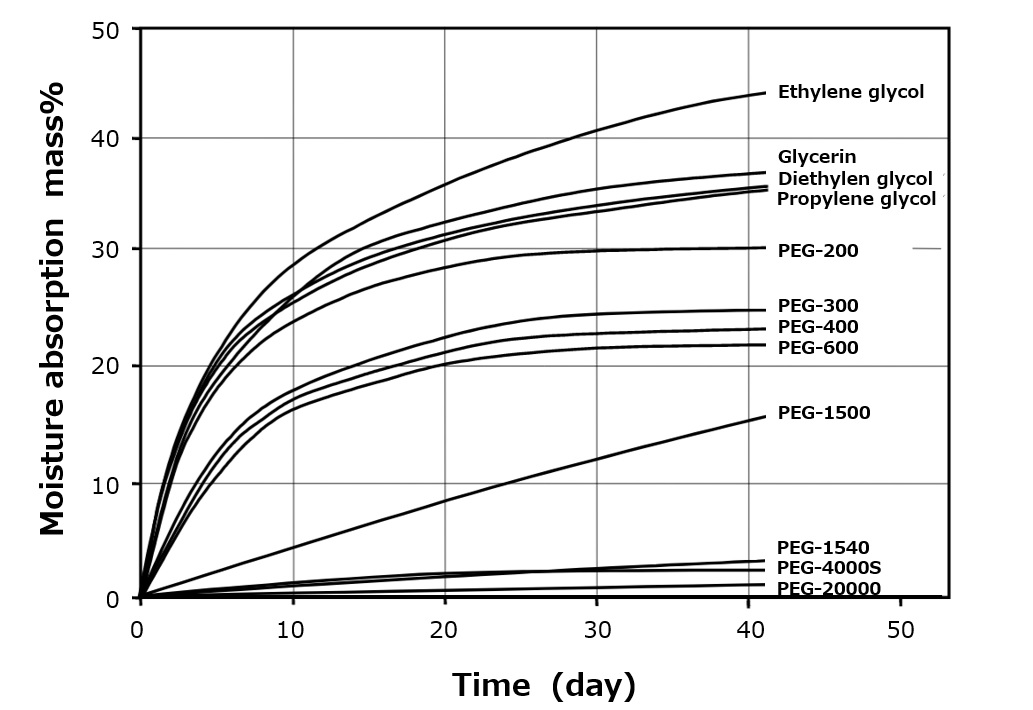

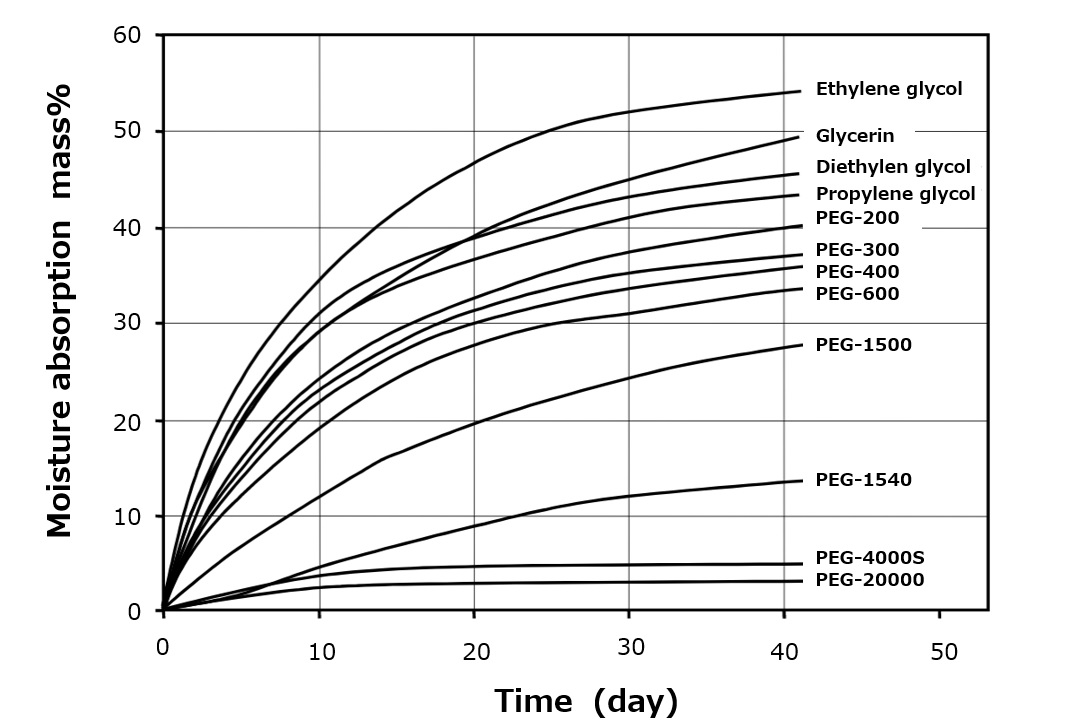

Polyethylene glycol (PEG) hygroscopicity

PEG is hygroscopic, but this hygroscopicity decreases as the molecular weight of PEG increases. For example, PEG-200 shows high hygroscopicity similar to propylene glycol, but PEG-4000S and PEG-20000 show very low hygroscopicity.

Saturated moisture absorption of PEG

Fig. Relative Humidity vs. Saturated Moisture Absorption

Hygroscopicity of PEG at 42% relative humidity

Fig. Relationship between time and moisture absorption at 42% relative humidity

[Test Method]

A 2 g sample was taken in a 20 mL beaker and left in a sealed desiccator with a relative humidity of 42%, and the amount of moisture absorption was measured from the sample's mass change.

Hygroscopicity of PEG at 65% relative humidity

Fig. Relationship between time and moisture absorption at 65% relative humidity

[Test Method]

A 2 g sample was taken in a 20 mL beaker and left in a sealed desiccator with a relative humidity of 42%, and the amount of moisture absorption was measured from the sample's mass change.

Hygroscopicity of PEG at 79.2% relative humidity

Fig. Relationship between time and moisture absorption at 79.2% relative humidity

[Test Method]

A 2 g sample was taken in a 20 mL beaker and left in a sealed desiccator with a relative humidity of 79.2%, and the amount of moisture absorption was measured from the sample's mass change.

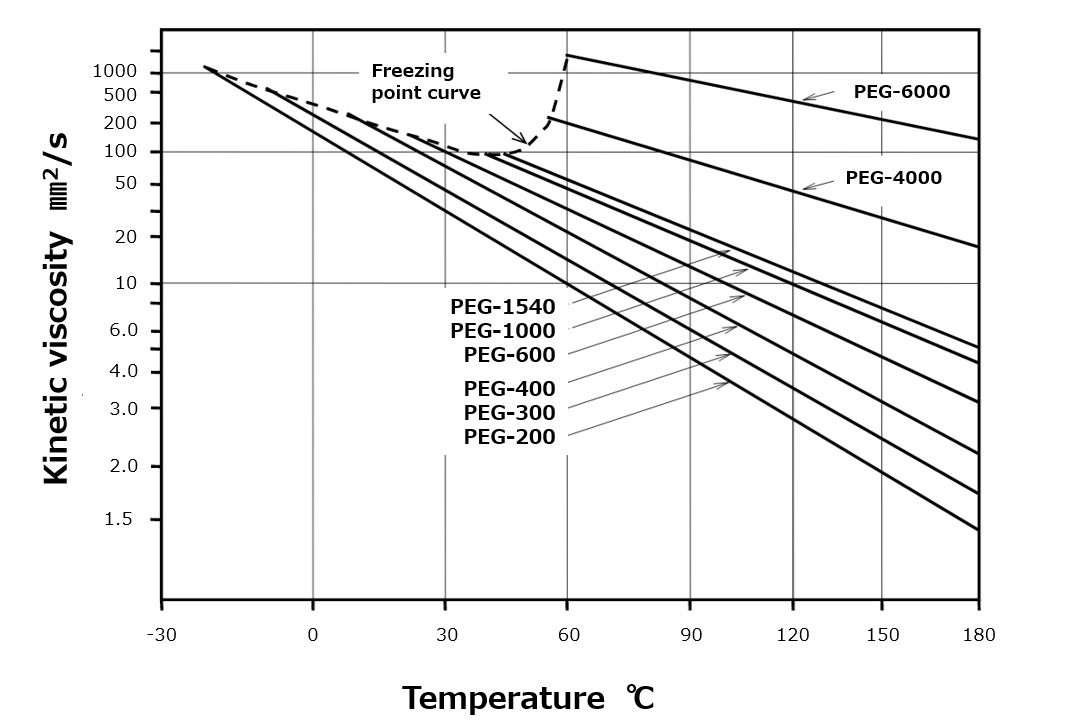

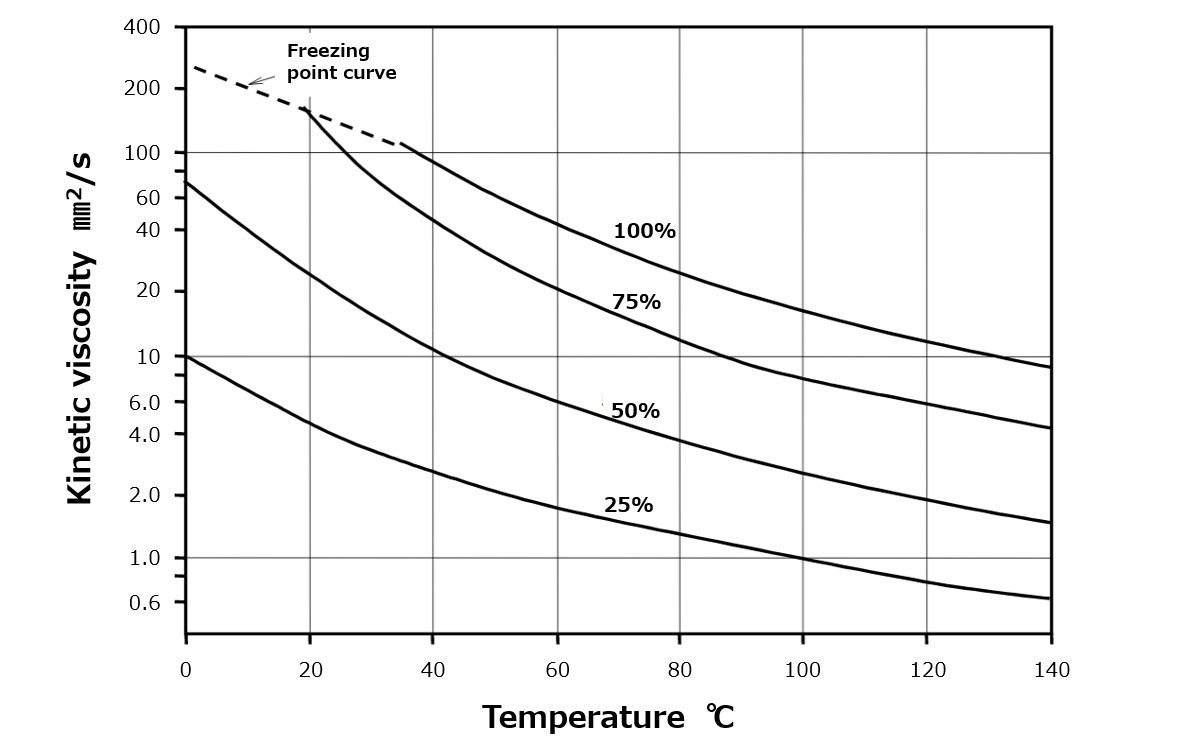

Kinematic viscosity curve of polyethylene glycol (PEG)

Temperature-Kinematic Viscosity Curve of PEG

Fig. Temperature-kinematic viscosity curve of PEG

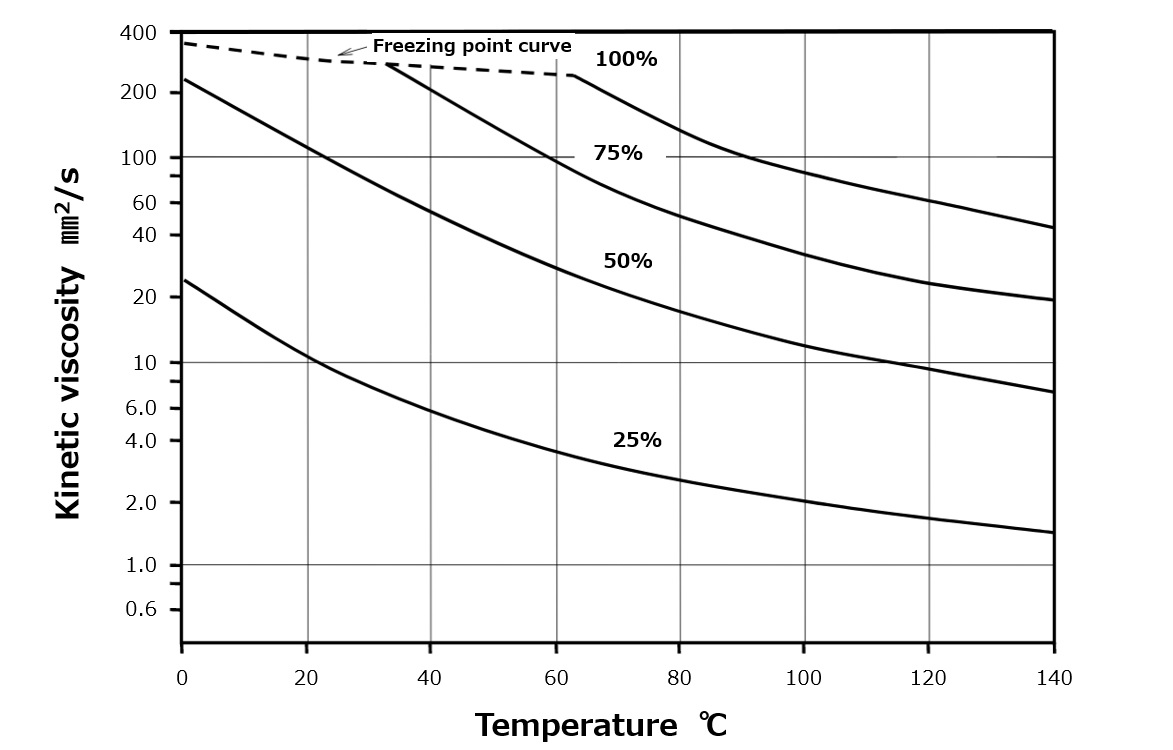

Temperature-kinematic viscosity curves of PEG-1000 and aqueous solutions

Fig. Temperature-kinematic viscosity curves of PEG-1000 and aqueous solutions

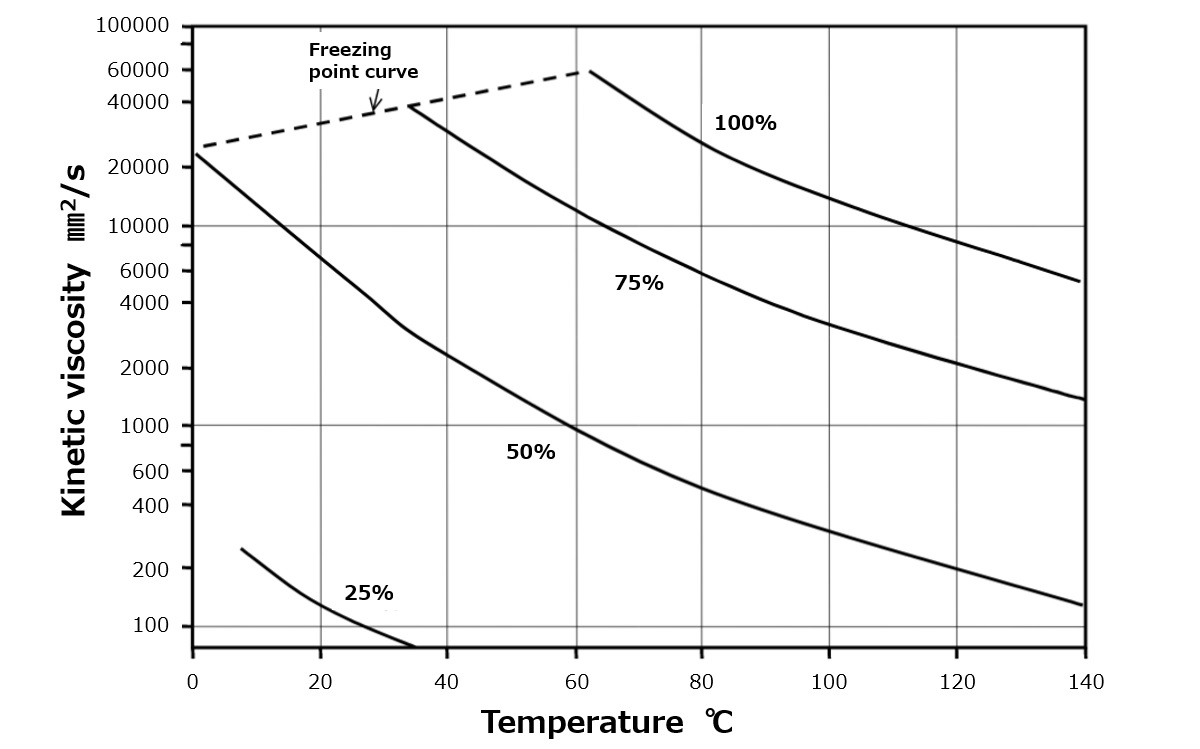

Temperature-kinematic viscosity curves of PEG-4000S and aqueous solutions

Fig. Temperature-kinematic viscosity curves of PEG-4000S and aqueous solutions

Temperature-kinematic viscosity curves of PEG-20000 and aqueous solutions

Fig. Temperature-kinematic viscosity curves of PEG-20000 and aqueous solutions

INCI Name / Packing

| INCI Name | Packing | |

|---|---|---|

| PEG-200 (polyethylene glycol 200) | PEG-4 | Can 20㎏ Drum 230kg |

| PEG-300 (polyethylene glycol 300) | PEG-6 | Can 20㎏ Drum 230kg |

| PEG-400 (polyethylene glycol 400) | PEG-8 | Can 20㎏ Drum 230kg |

| PEG-600 (polyethylene glycol 600) | PEG-12 | Can 20㎏ Drum 230kg |

| PEG-1000 (polyethylene glycol 1000) | PEG-20 | Can 20㎏ Drum 230kg |

| PEG-1500 (PEG-1500 is a mixture of PEG-300 and PEG1540) | PEG-6 and PEG-32 | Can 20㎏ Drum 230kg |

| PEG-1540 (polyethylene glycol 1540) | PEG-32 | Can 20㎏ Drum 230kg |

| PEG-2000 (polyethylene glycol 2000) | PEG-40 | Can 20㎏ Drum 230kg |

| PEG-4000N (polyethylene glycol 4000) | PEG-75 | Bag 20kg |

| PEG-4000S (polyethylene glycol 4000) | PEG-75 | Bag 20kg |

| PEG-6000P (polyethylene glycol 6000) | PEG-150 | Bag 20kg |

| PEG-6000S (polyethylene glycol 6000) | PEG-150 | Bag 20kg Drum 200kg |

| PEG-10000 (polyethylene glycol 10000) | PEG-240 | Bag 15kg |

| PEG-20000 (polyethylene glycol 20000) | PEG-400 | Bag 15kg |

Related Information

Related products

- Polyether products

- Link to Sanyo Chemical's corporate website

Technology topics

This page has been prepared solely for information purposes.

Sanyo Chemical Industries, Ltd. extends no warranties and makes no representations as to the accuracy or completeness of the information contained herein, and assumes no responsibility regarding the suitability of this information for any intended purposes or for any consequences of using this information.

Any product information in this brochure is without obligation and commitment, and is subject to change at any time without prior notice.

Consequently anyone acting on information contained in this brochure does so entirely at his/her own risk.In particular, final determination of suitability of any material described in this brochure, including patent liability for intended applications, is the sole responsibility of the user. Such materials may present unknown health hazards and should be used with caution. Although certain hazards may be described in this brochure, Sanyo Chemical Industries, Ltd. cannot guarantee that these are the only hazards that exist